A hoop prestressed reinforced tunnel segment and its manufacturing method

A tunnel segment and prestressing technology, applied in tunnels, tunnel lining, earthwork drilling, etc., can solve the problems of weakening segment strength and difficulty in passing steel strands, so as to improve water seepage resistance, save manpower, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

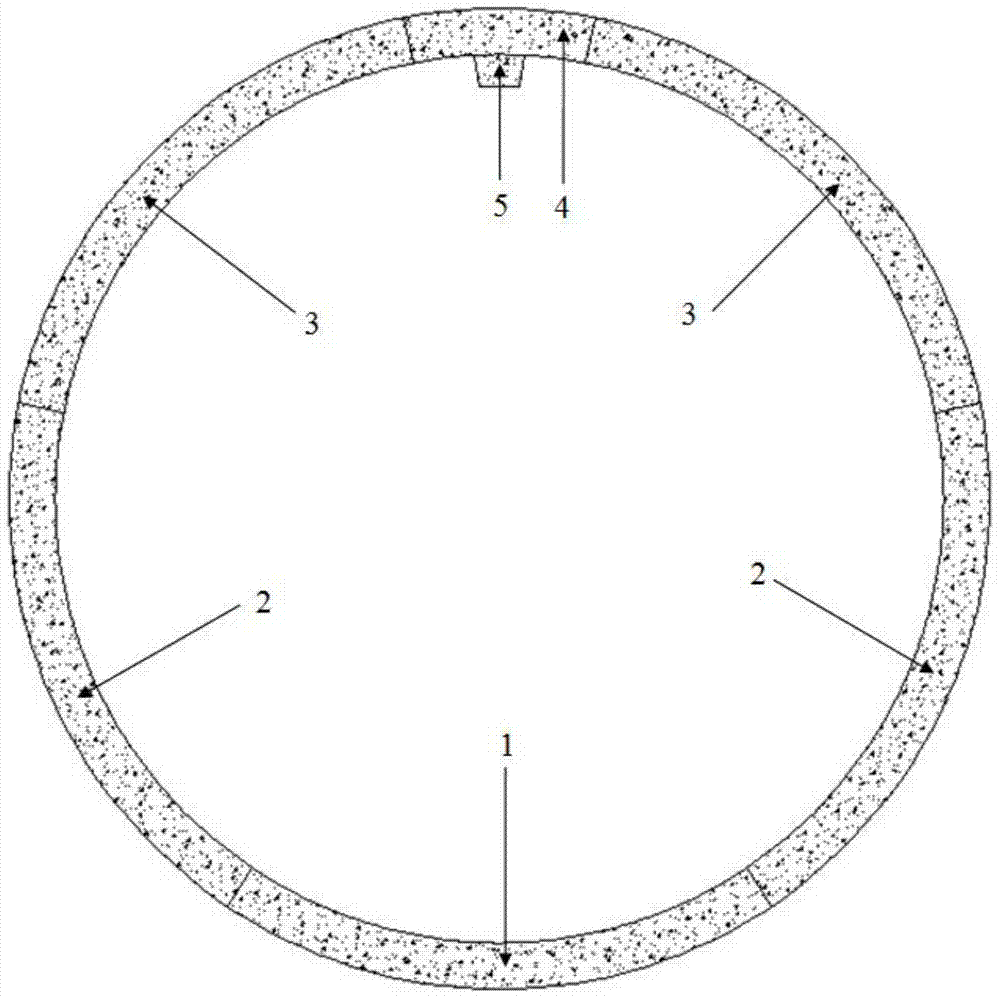

[0040] Embodiment: A kind of hoop prestressed reinforcement tunnel segment, its lateral structure is as follows figure 1 and Figure 6 As shown, including arch bottom block 1, the two ends of arch bottom block 1 are respectively provided with an adjacent block 2, the end of any adjacent block 2 is close to a connecting block 3, and the capping block is between the two connecting blocks 3 4;

[0041] The outer sides of the arch bottom block 1, the adjacent block 2, the connecting block 3 and the capping block 4 are all provided with reserved grooves 7, and there are at least three reserved grooves 7. After the end of each reserved groove is extended, a closed pure circle can be formed.

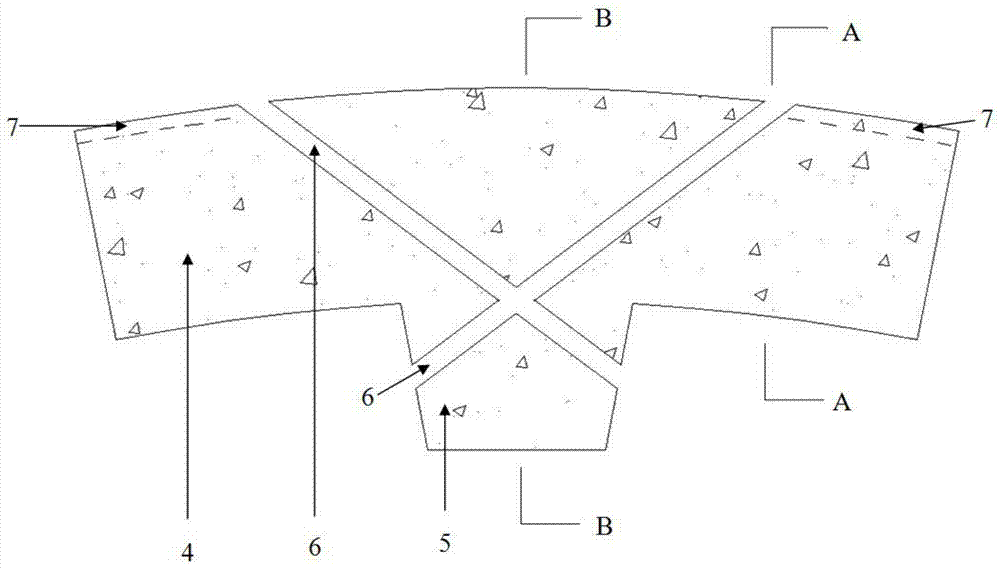

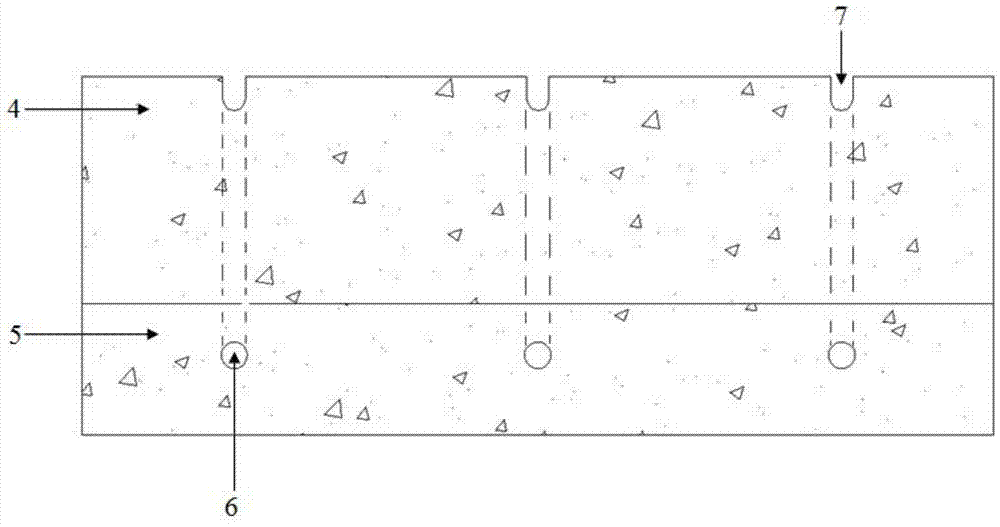

[0042] refer to Figure 2-Figure 4 As shown, there are reserved channels 6 inside the capping block 4. On the basis of having three reserved grooves 7, the number of reserved channels 6 is 6, and every two reserved channels 6 correspond to each other, and the corresponding The direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com