Differential gear forming die

A gear forming and differential technology, applied in metal extrusion dies and other directions, can solve the problems of insufficient prestress and low die life, and achieve the effect of easy installation and manufacturing, improving bearing capacity and service life, and saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

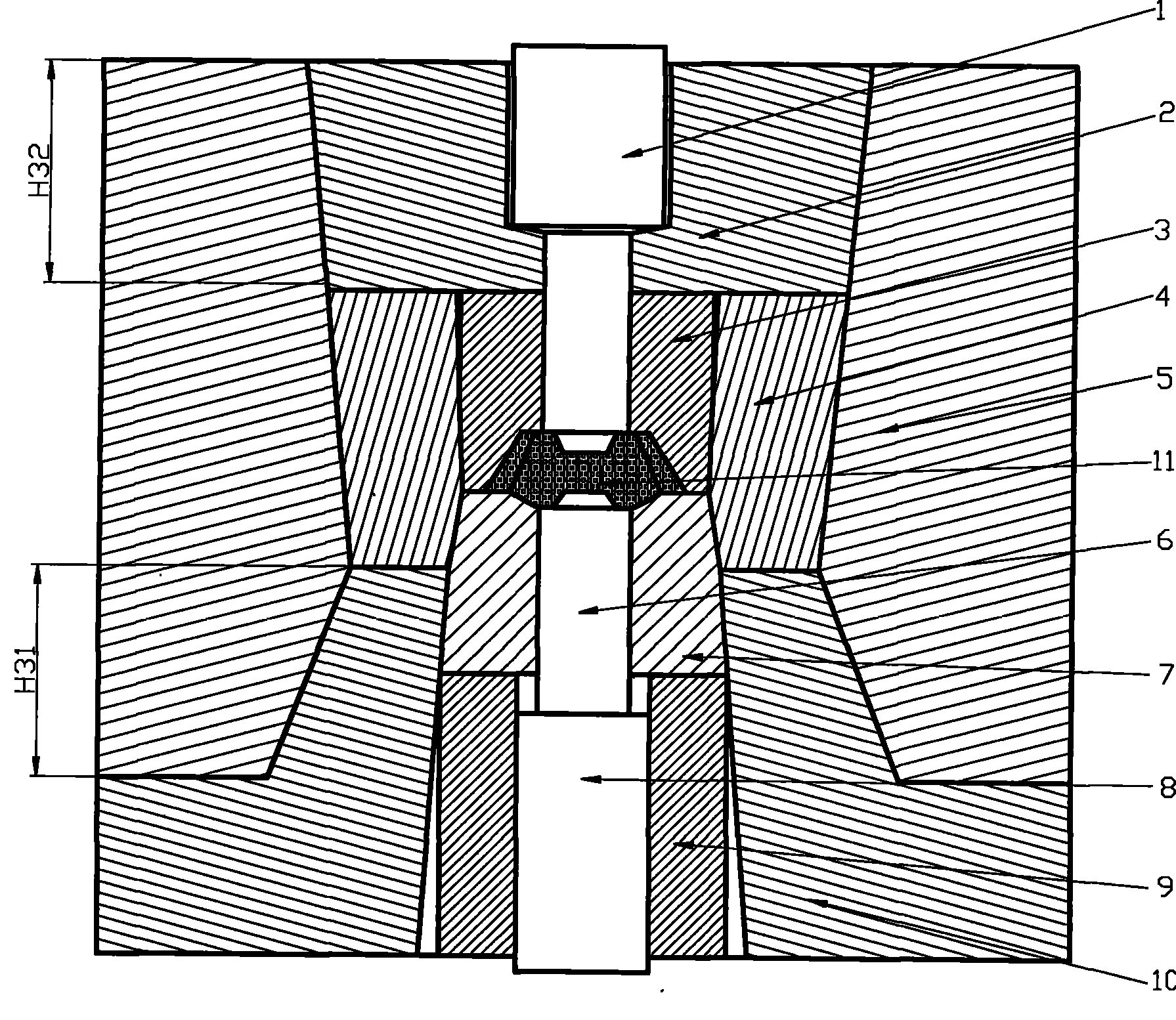

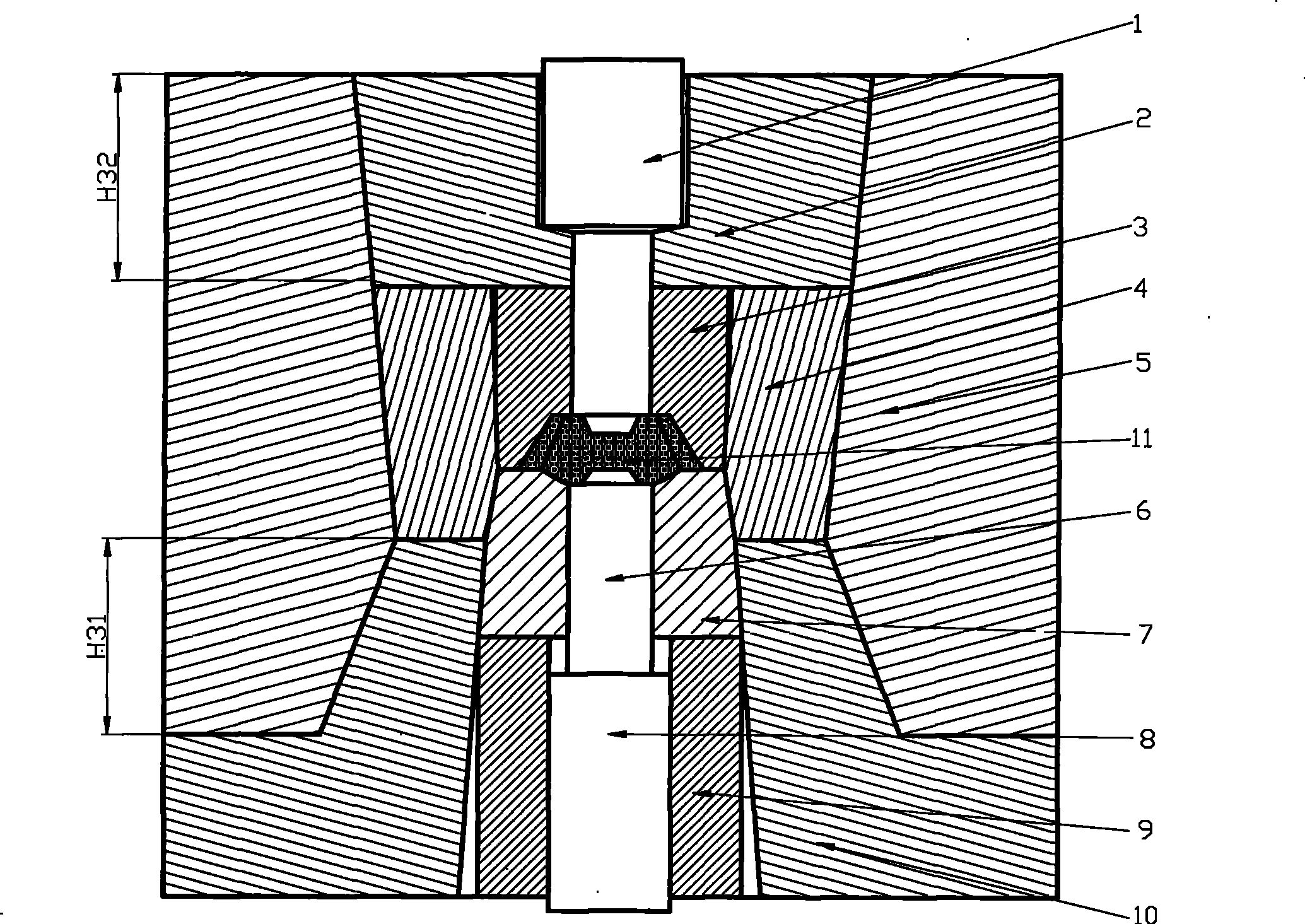

[0021] As shown in Figure 1, the present invention consists of upper and lower dies arranged up and down. The structure of the upper die is as follows: the upper punch 1 passes through the upper die pad 2 and the upper die 3 in turn, and the upper die 3 is covered with an upper die The prestressed inner ring 4 and the prestressed outer ring 5 of the upper die; the structure of the lower die is: the lower push rod 8 passes through the lower die pad 9 and contacts the lower punch 6, and the lower punch 6 passes through the lower die 7; the lower die The pad 9 and the lower die 7 are covered with a lower die prestressing ring 10 . After extrusion, the forging 11 is located in the cavities of the upper die 3 and the lower die 7 .

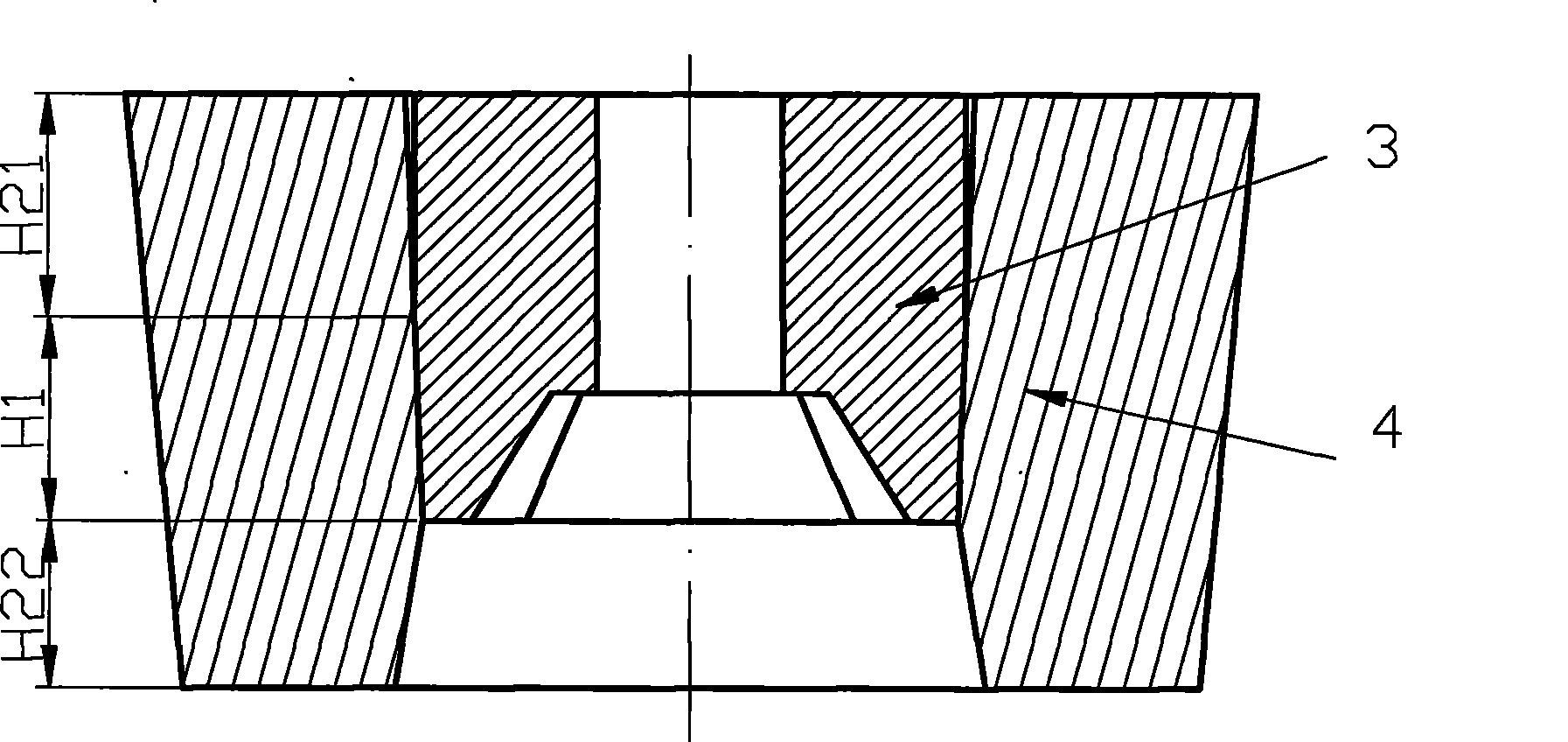

[0022] As shown in Fig. 1 and Fig. 2, the optimal size relationship of the upper die pad 2, the upper die 3, the upper die prestressed inner ring 4 and the upper die prestressed outer ring 5 is: H31=H32=H21+H22+ H1, H21=H22=H1;

[0023] In the formula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com