Super high-rise building foundation raft construction method

A foundation raft and construction method technology, which is applied in the direction of basic structure engineering, construction, excavation, etc., can solve the problems of low standardization, impact on construction period, lack of unified and effective water retaining means, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

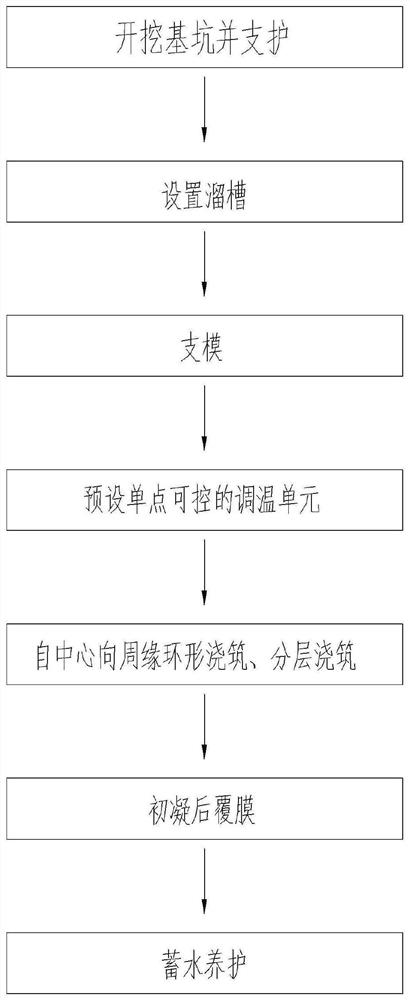

[0041] Such as figure 1 As shown, the concrete steps of the foundation raft construction method of this super high-rise building provided by this embodiment are as follows.

[0042] The first step is to excavate the foundation pit and support it. Take Shandong Rizhao Haiyun Plaza as an example. The plane size of the foundation raft in this project is 62*55 meters, and the thickness is 4.2 meters. The height difference between the inner part of the foundation pit and the ground is 3.6 meters, and the height difference between it and the auxiliary road of Qingdao Road is about 18 meters. The total volume of concrete is 16,000 cubic meters.

[0043] The second step is to set the main chute and the auxiliary chute, the main chute is connected with the center of the foundation pit, and the auxiliary chute is arranged in the foundation pit. Since the highest difference occurs at the auxiliary road of Qingdao Road, the main chute is set from the auxiliary road of Qingdao Road to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com