Construction process of building ecological roof system

A technology of roofing system and construction technology, which is applied in the direction of roofing, buildings, building components, etc., can solve the problems of low thermal insulation and heat resistance performance of the roof, high energy consumption of the roof, etc., and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

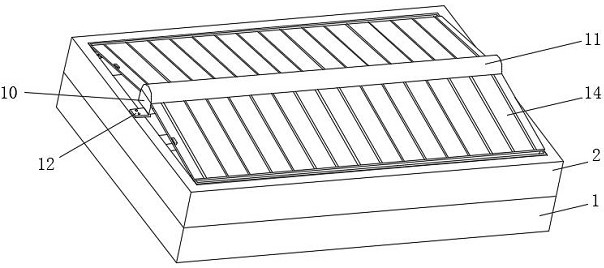

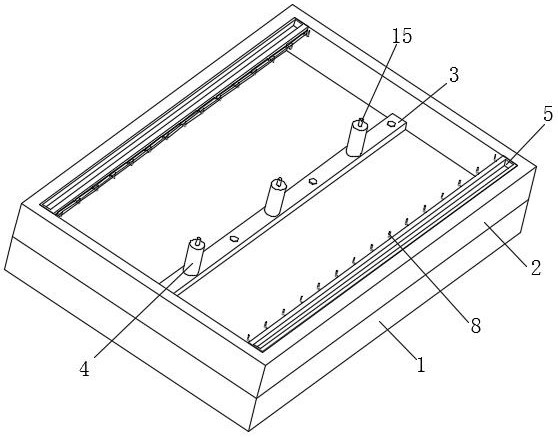

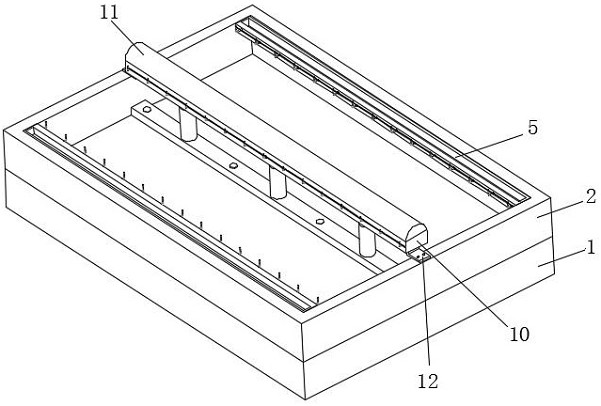

[0032] see Figure 1-7 , a kind of construction technique of building ecological roofing system, comprises the following steps:

[0033] Step 1: Clean the top of the building body 1 in advance, level the top of the building body 1, and spray a waterproof coating on the top of the building body 1. In the process of spraying the waterproof coating, the waterproof coating must be applied twice, and every The thickness of the paint for one pass is 1, and the next pass should be carried out after the previous pass is completely dry. The waterproof coating can prevent moisture from corroding the top of the building body 1;

[0034] Step 2: Measure the top of the building body 1 and the front and rear inner walls of the parapet 2, and mark and punch holes on the top of the building body 1 and the front and rear inner walls of the parapet 2, and the parapet 2 is fixedly connected to the top of the building body 1 Four sides, and the lower end of the retaining wall 2 on the back is pr...

Embodiment 2

[0039] see Figure 1-7 , a kind of construction technique of building ecological roofing system, comprises the following steps:

[0040]Step 1: Clean the top of the building body 1 in advance, level the top of the building body 1, and spray a waterproof coating on the top of the building body 1. In the process of spraying the waterproof coating, the waterproof coating must be painted 3 times, and each time The thickness of the paint for one pass is 1.5 mm, and the next pass should be carried out after the previous pass is completely dry. The waterproof coating can prevent moisture from corroding the top of the building body 1;

[0041] Step 2: Measure the top of the building body 1 and the front and rear inner walls of the parapet 2, and mark and punch holes on the top of the building body 1 and the front and rear inner walls of the parapet 2, and the parapet 2 is fixedly connected to the top of the building body 1 Four sides, and the lower end of the retaining wall 2 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com