Internal spiral injection type solid-liquid engine grain

An engine and internal screw technology, applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve problems such as uneven receding of the combustion surface, achieve combustion control and precise power adjustment, improve mechanical performance, and enhance internal transmission. hot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

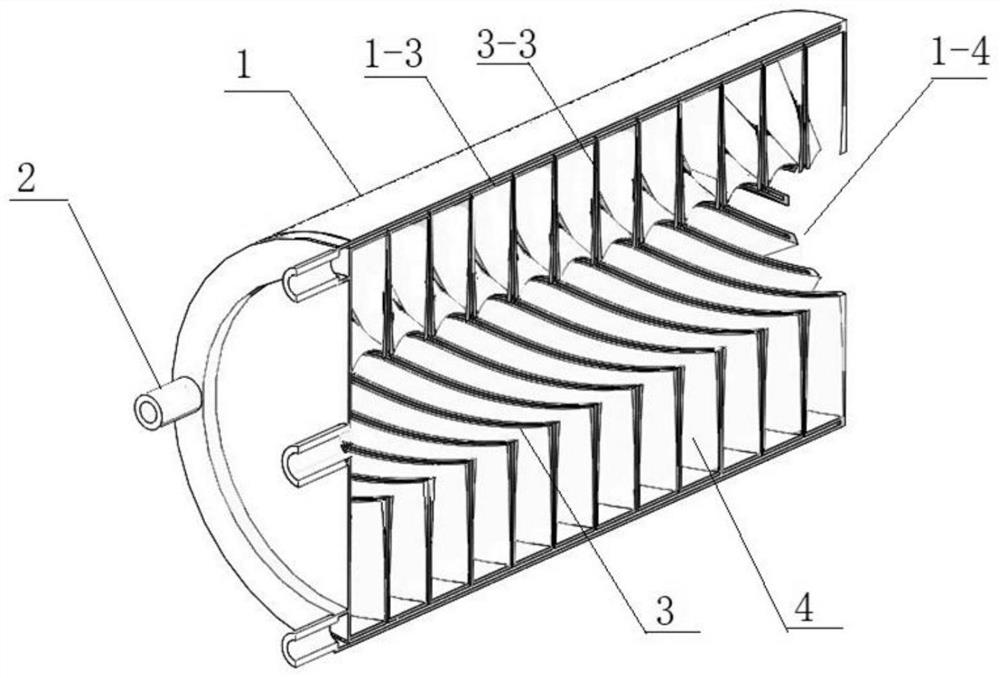

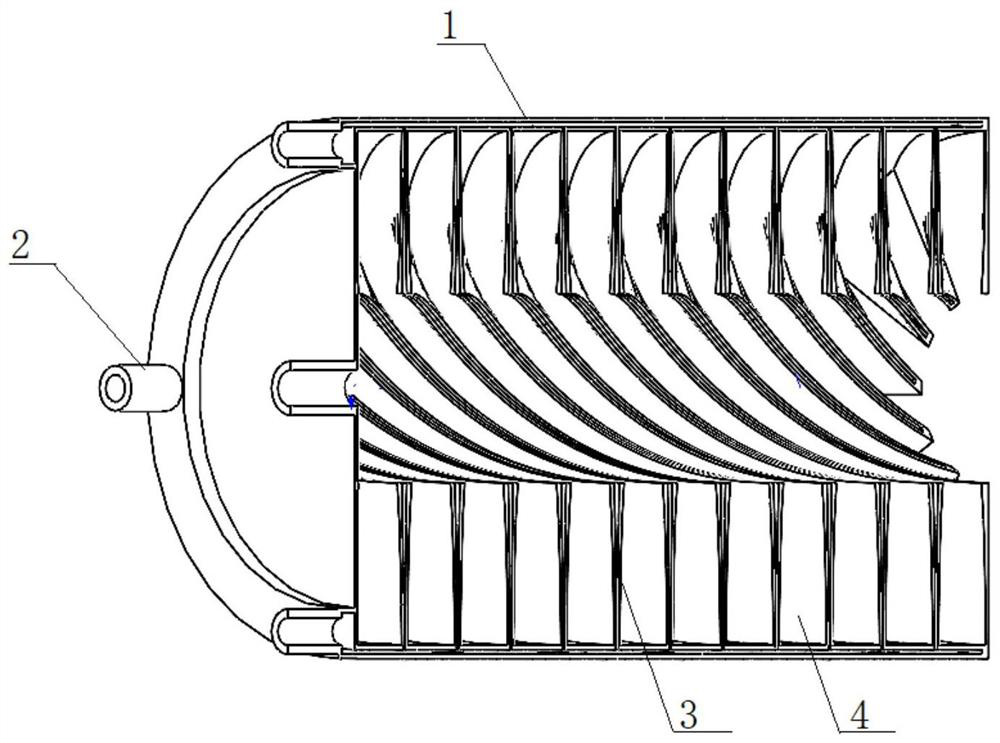

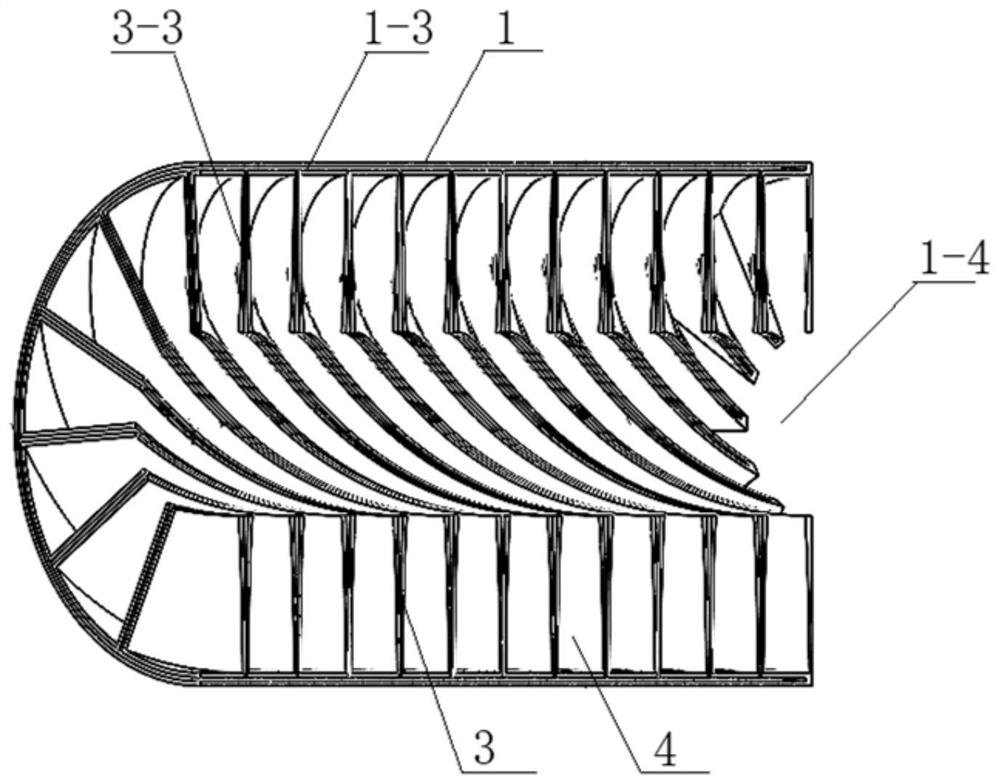

[0028] Such as Figure 1 to Figure 4 As shown, an internal spiral injection solid-liquid engine grain, the grain includes a metal frame body 1, and the metal frame body 1 is integrally formed by additive manufacturing technology; the metal frame body 1 is set as a hollow structure, There are multiple sets of uniformly arranged hollow spiral structure blades inside, and a fuel medium 4 is nested between each adjacent two sets of hollow spiral structure blades. The fuel medium 4 is a conventional solid-liquid engine fuel such as paraffin-based fuel, HTPB , PMMA, etc. The end of the metal frame body 1 is provided with an air inlet pipe 2, and the oxidant is evenly injected from the helix of the hollow spiral structure blade after passing through the air inlet pipe 2.

[0029] Through the special structural design of the grain, the technical breakthrough of uniform and spiral injection of oxidant inside the solid-liquid engine grain is realized, so that the uniform retreat of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com