Fan assembly and inverter

A fan assembly and inverter technology, applied to pump components, electrical components, non-variable pumps, etc., can solve the problems of increasing the vibration of the fan assembly, increasing the noise of the fan assembly, and increasing the aerodynamic noise, etc., to achieve improved Effects of transmission loss, efficient heat dissipation, and noise improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

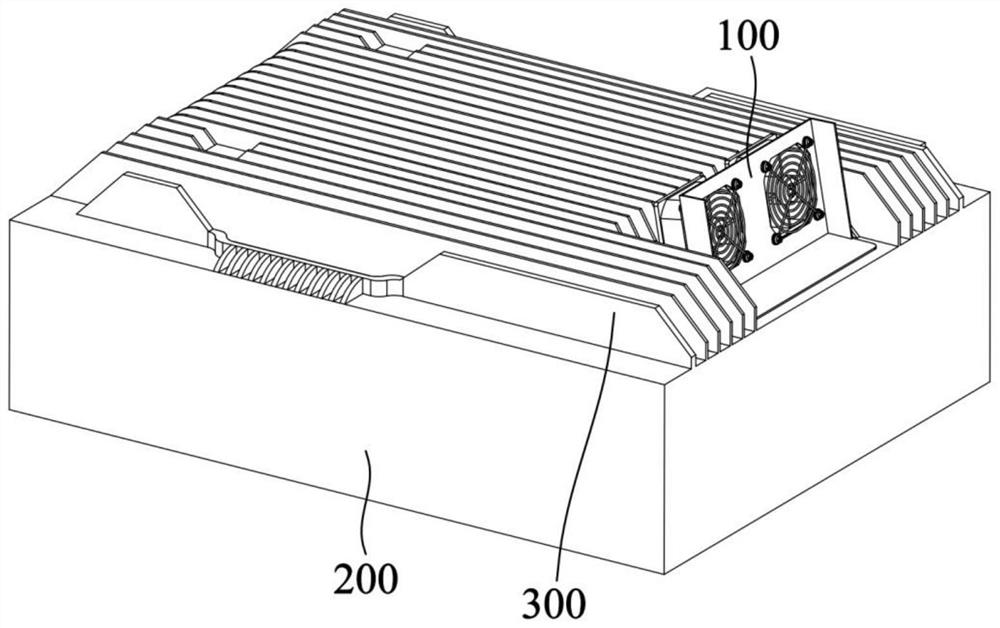

[0052] Such as figure 1 As shown, the present embodiment provides a fan assembly 100, the fan assembly 100 is mainly used to dissipate heat for an inverter, but is not limited thereto, and may also dissipate heat for other devices.

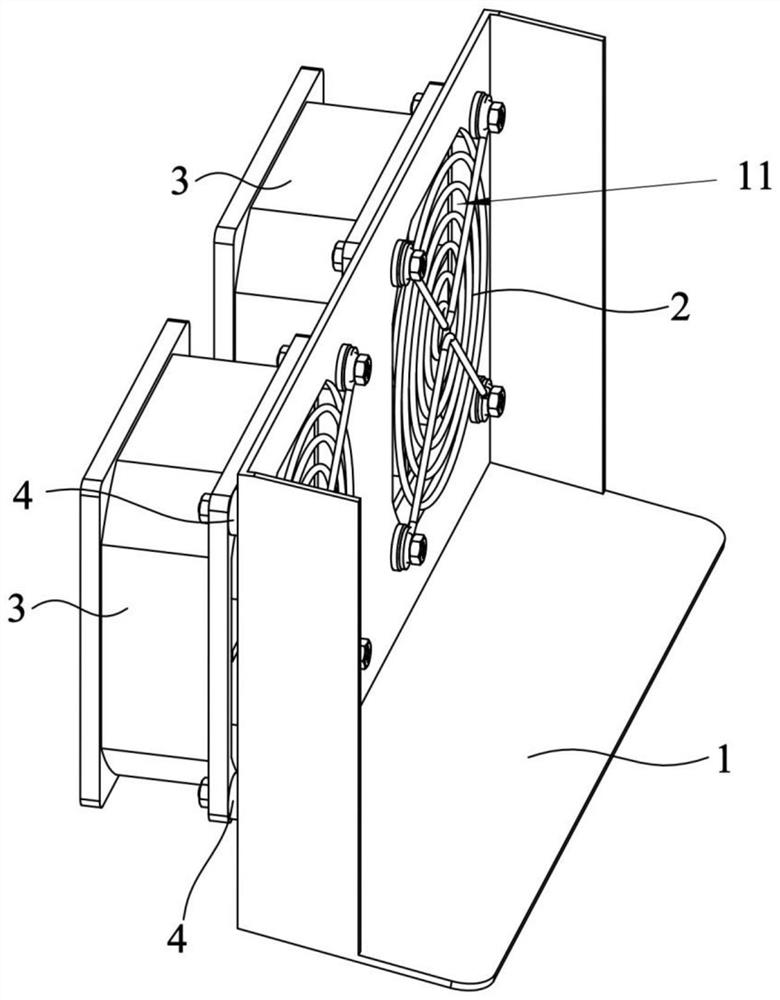

[0053] Specifically, as figure 2 As shown, the fan assembly 100 provided in this embodiment includes a fan bracket 1, a fan guard 2 and a fan main body 3, the fan bracket 1 is provided with an air inlet 11, the air inlet 11 is covered with the fan guard 2, and the fan main body 3 is installed On the fan bracket 1 and facing the air inlet 11, the fan guard 2 can ensure the air circulation at the air inlet 11, and also protect the fan main body 3 to prevent foreign matter from entering the fan main body 3 and causing danger. Avoid accidentally touching the fan body 3 to ensure personal safety. The main body of the fan 3 rotates so that the air passes through the fan guard 2 from the air inlet 11 to realize air circulation and realize the effect o...

Embodiment 2

[0082] The structure of the fan assembly 100 disclosed in this embodiment is basically the same as that of Embodiment 1. The difference between the fan assembly 100 disclosed in this embodiment and Embodiment 1 lies in that: the fan main body 3 and the noise reduction mounting part 4 are integrally formed.

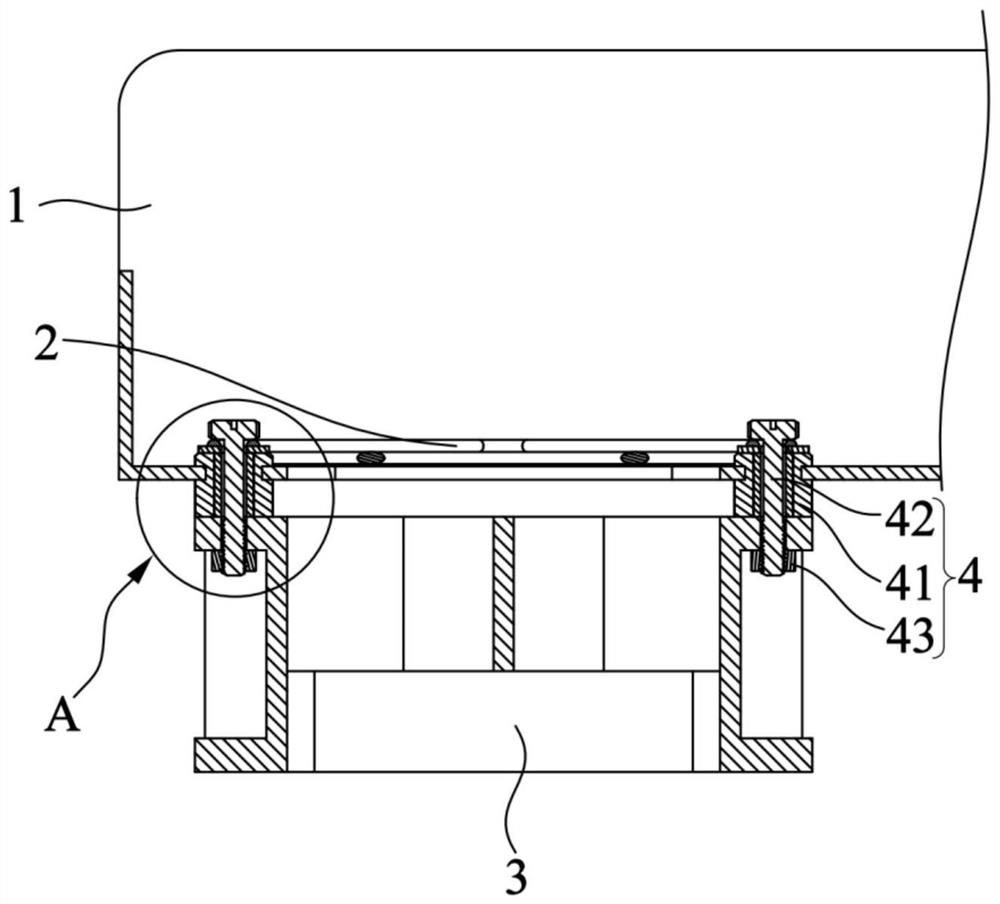

[0083] Specifically, as Figure 7 As shown, the fan body 3 and the vibration-damping foot pad 411 are integrally formed, which improves the connection stability between the fan body 3 and the vibration-damping foot pad 411, and facilitates the installation of the fan body 3 on the fan bracket 1. Only the vibration-damping The clamping groove 4112 of the foot pad 411 is clamped into the third installation hole 12 and passes through.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap