Static pressure air floatation supporting device with extrusion film assisting in pressure stabilization and control method

A technology of supporting device and extruding film, applied in the directions of bearings, shafts and bearings, mechanical equipment, etc., can solve problems such as adverse effects on the stability of floating bodies, and achieve the effects of avoiding resonance, suppressing low-frequency vibration, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

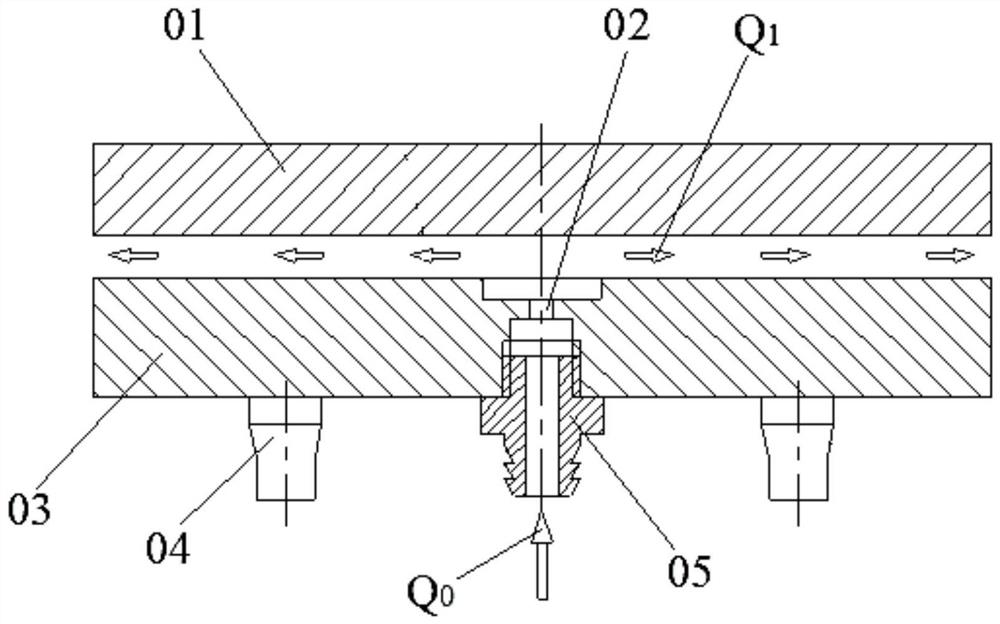

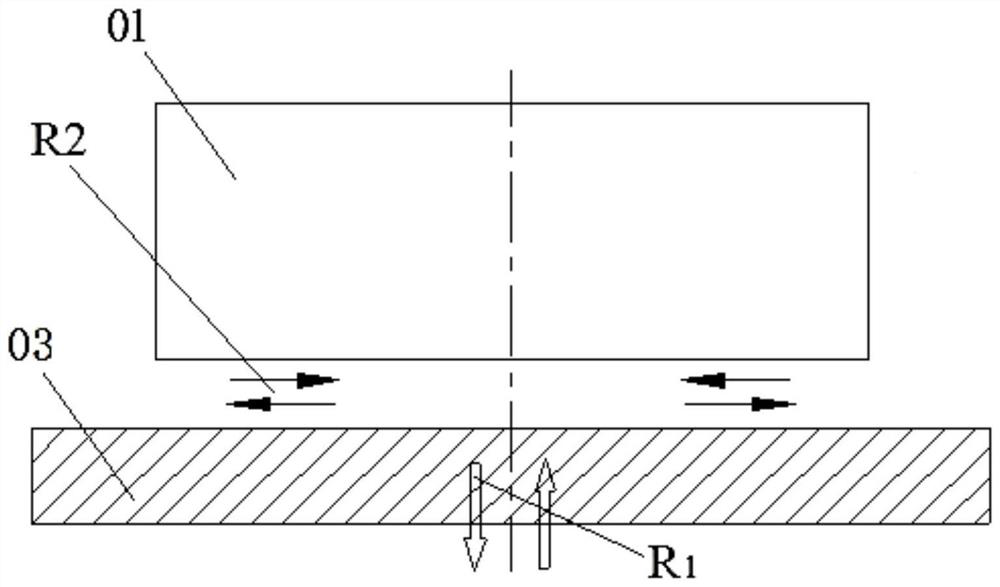

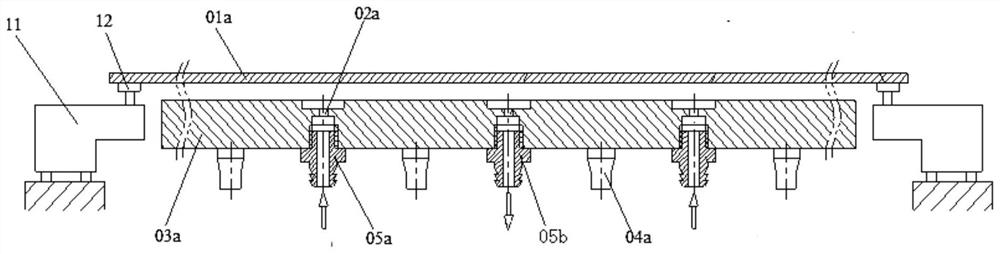

[0016] Such as figure 1 As shown, the basic device of the present invention includes a floating body 01 and a carrier 03 facing up and down, wherein the floating body 01 is on top and the carrier 03 is on the bottom, and the lower surface of the floating body 01 and the upper surface of the carrier 03 are parallel to each other. An axial vertical throttling hole 02 and a mounting hole are provided in the middle of the carrier 03, wherein the upper end of the throttling hole 02 is located on the upper surface of the carrier 03, the lower end of the throttling hole 02 communicates with the upper end of the mounting hole coaxially, and the lower end of the mounting hole Located on the lower surface of the carrier 03. The air supply nozzle 05 is used as the air supply device in the basic device of the present invention, and the air supply nozzle 05 is coax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com