High-temperature-resistant gas one-way valve

A gas one-way valve, high-temperature resistant technology, applied in the field of valves, can solve problems such as equipment failure production accidents, affecting the interests and safety of enterprises, and non-functioning one-way valves, achieving good sealing and heat insulation performance, improving service life, and facilitating Control the effect of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

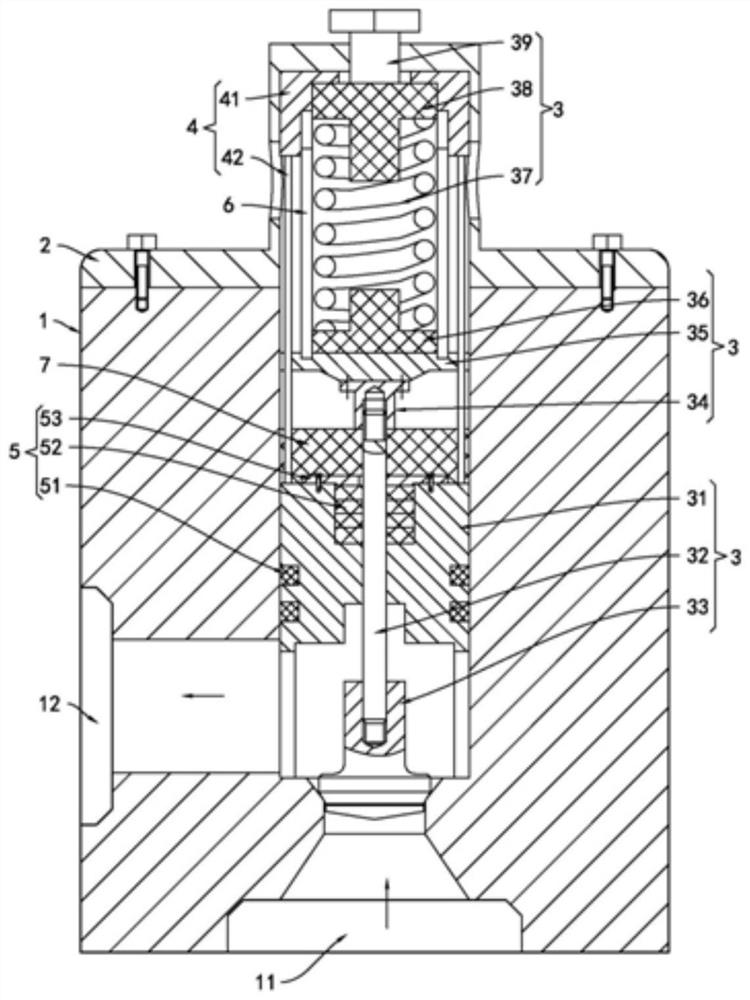

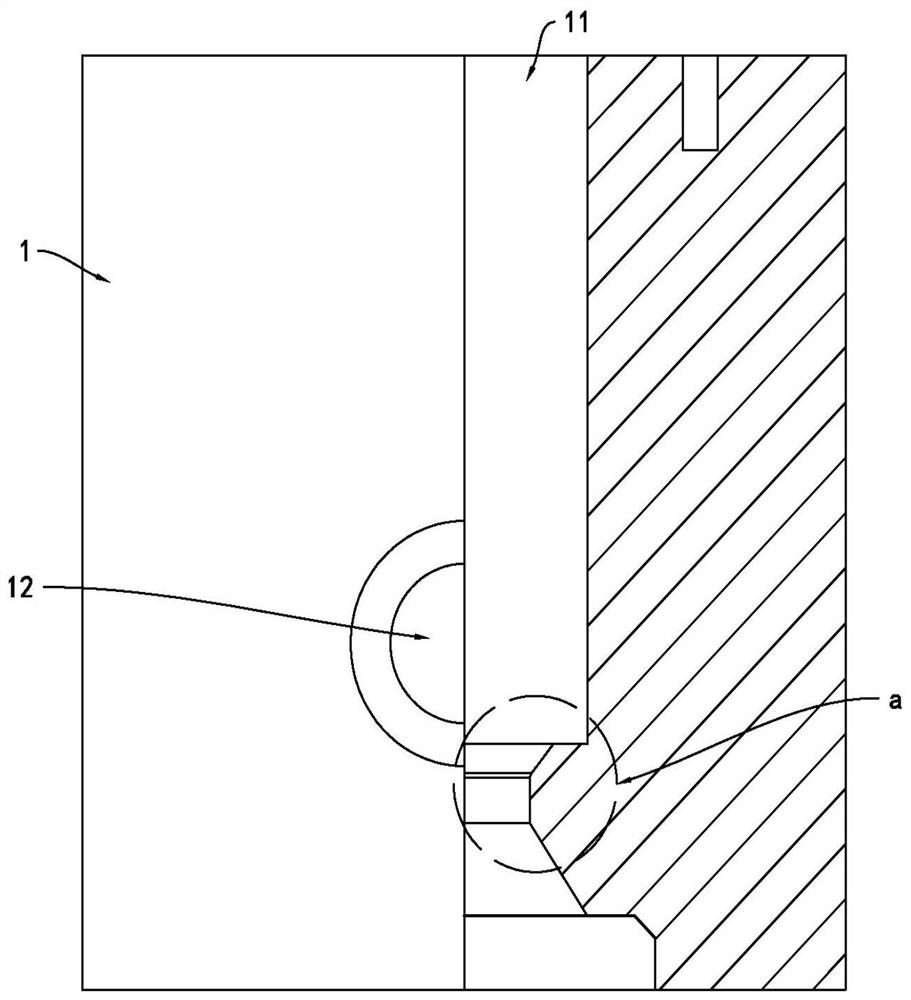

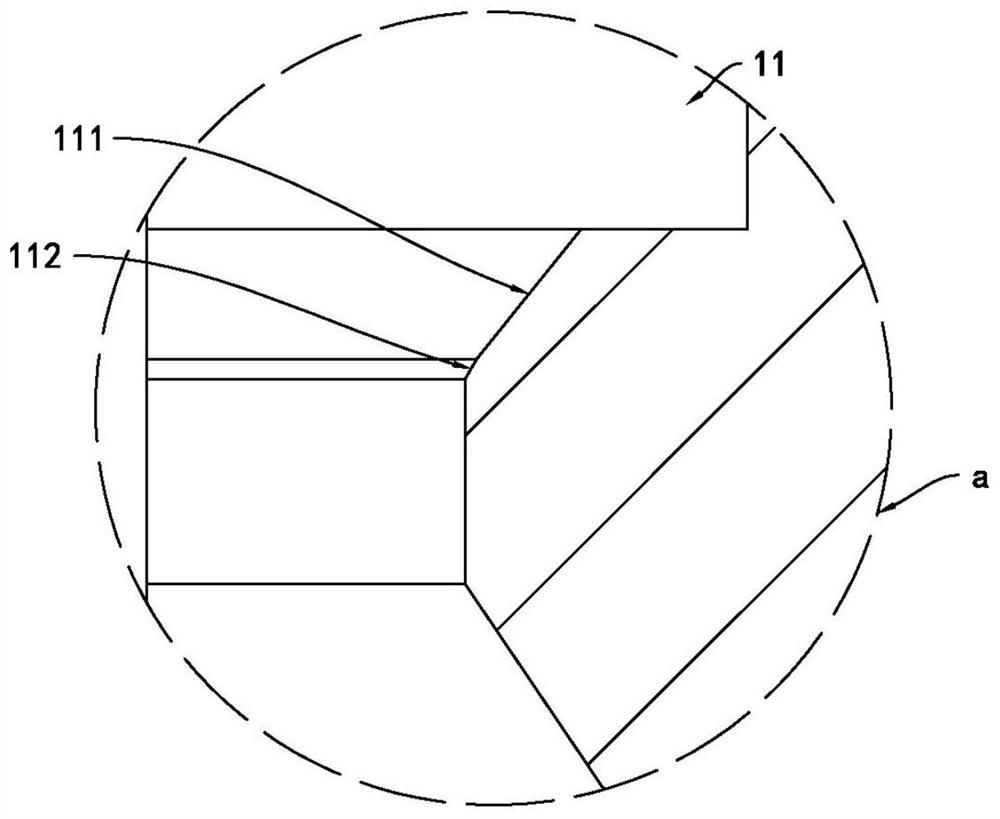

[0030] A kind of high temperature resistant gas one-way valve of the present invention, as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, the valve body 1 is included, the bottom end of the valve body 1 is provided with a first cavity 11, the side wall of the valve body 1 is provided with a second cavity 12, the first cavity 11 communicates with the second cavity 12, and the first cavity A valve cover 2 is installed on the top of the cavity 11, the first cavity 11 is provided with a stepped hole 111, the stepped hole 111 is located below the second cavity 12, and a tapered sealing surface 112 is ground on the stepped hole 111; the sealing valve body 1 A spool assembly 3 is provided, and the spool assembly 3 is located in the first cavity 11; a compression assembly 4 is installed on the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com