Vacuum-compatible planar optical element adjusting device

An optical element and adjustment device technology, applied in the field of optical instruments, can solve the problems of complex displacement adjustment structure of optical elements, unfavorable vacuum environment application, etc., and achieve the effects of increasing adjustment dimensions and structural transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

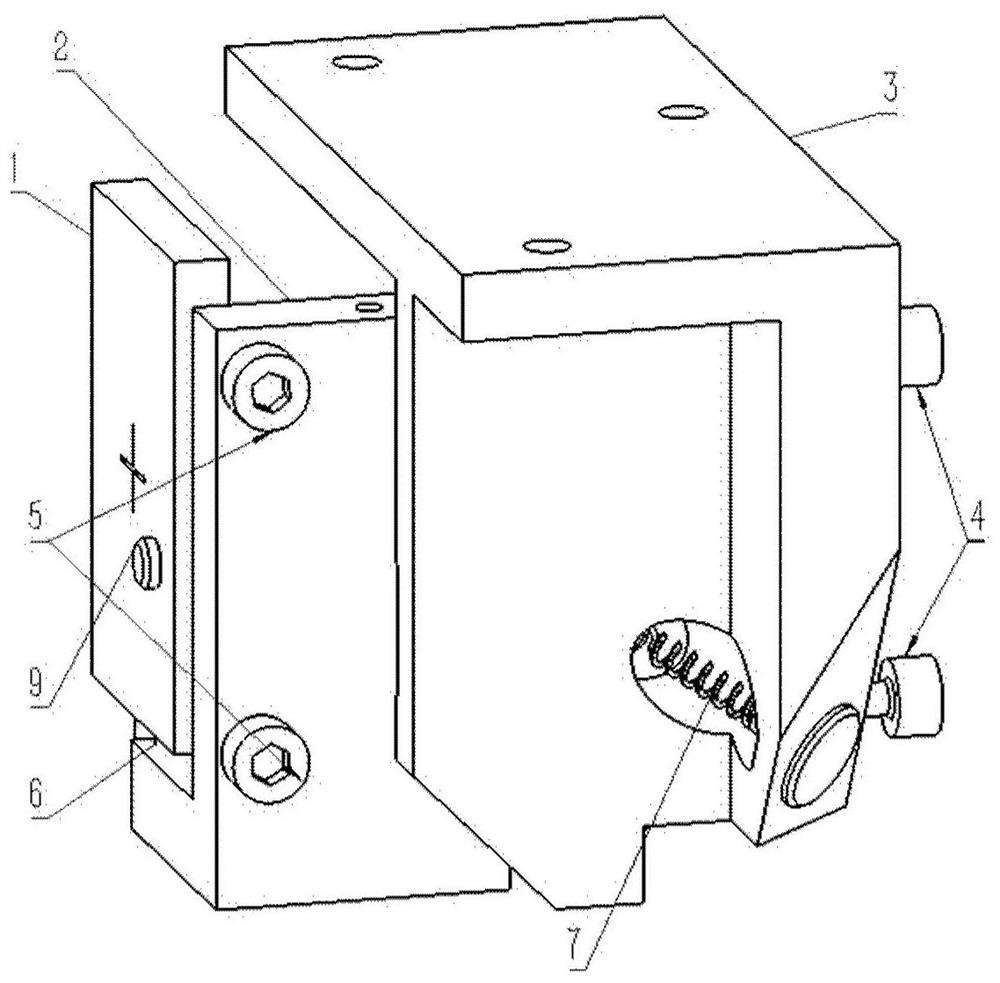

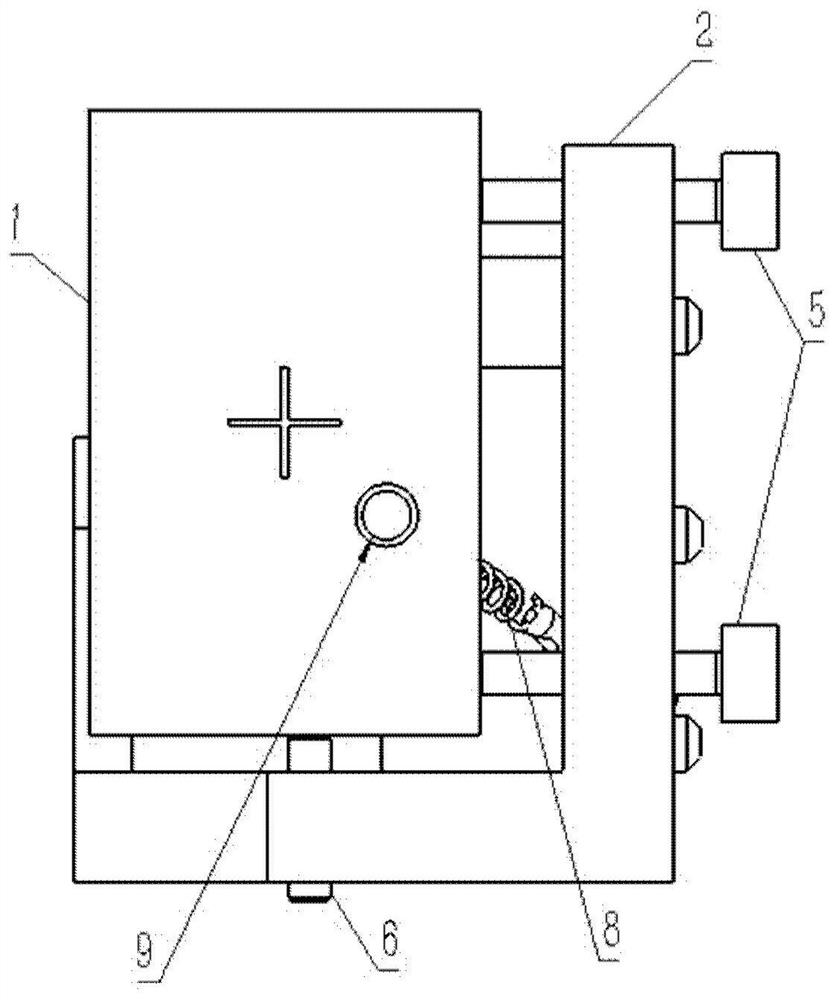

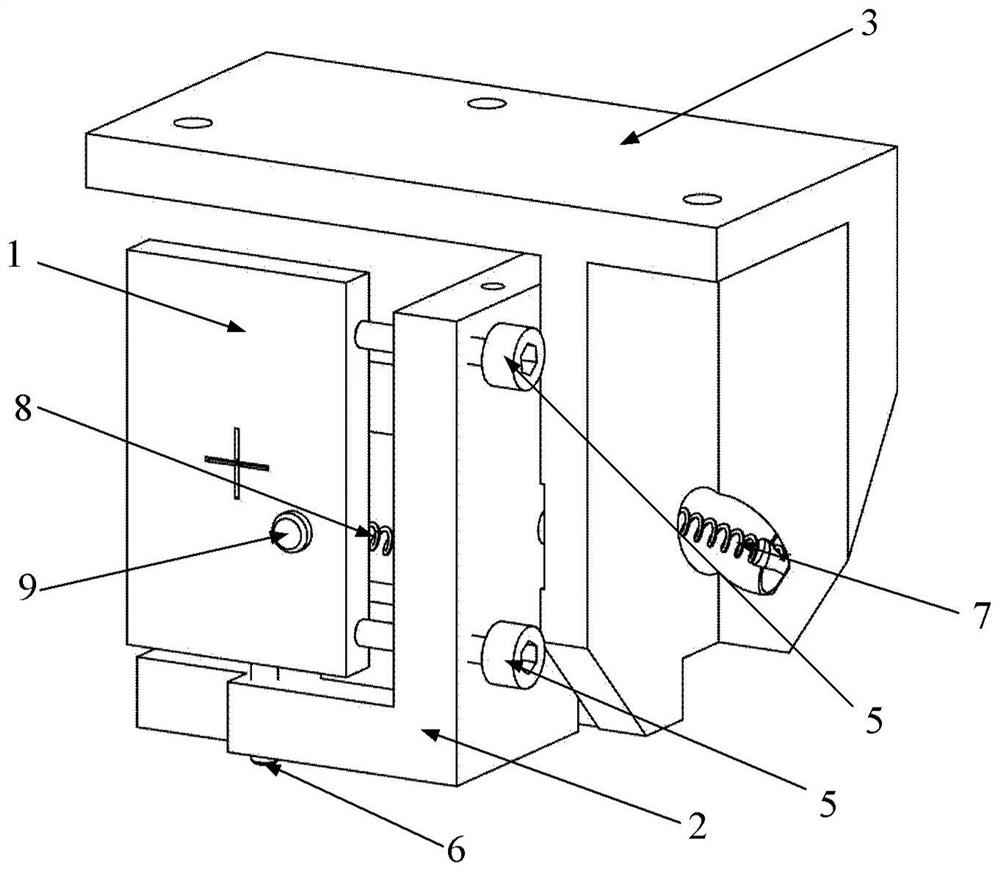

[0042] In an embodiment of the present disclosure, a vacuum compatible planar optical element adjustment device is provided, such as Figures 1 to 3 Shown, described preparation method comprises:

[0043] A planar optical element 1, including mutually perpendicular optical surfaces, side surfaces and bottom surfaces;

[0044] The first adjustment bracket 2 is connected with the planar optical element 1 and can move the planar optical element 1 within the plane where the optical surface is located;

[0045] The second adjustment bracket 3 is connected with the first adjustment bracket 2 and can move the planar optical element 1 in the plane where the side surface is located.

[0046] In the embodiment of the present disclosure, the planar optical element 1 includes a pin 9, and the pin 9 is connected to the first adjustment bracket 2 through a first spring 8, and the first spring 8 holds the plane The optical element 1 is connected against the first adjustment bracket 2 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com