Flexible Cover Window and Manufacturing Method of Flexible Cover Window

A manufacturing method and flexible technology, applied in chemical instruments and methods, identification devices, instruments, etc., can solve the problems of low mechanical strength, expensive, folded parts of polymer membranes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

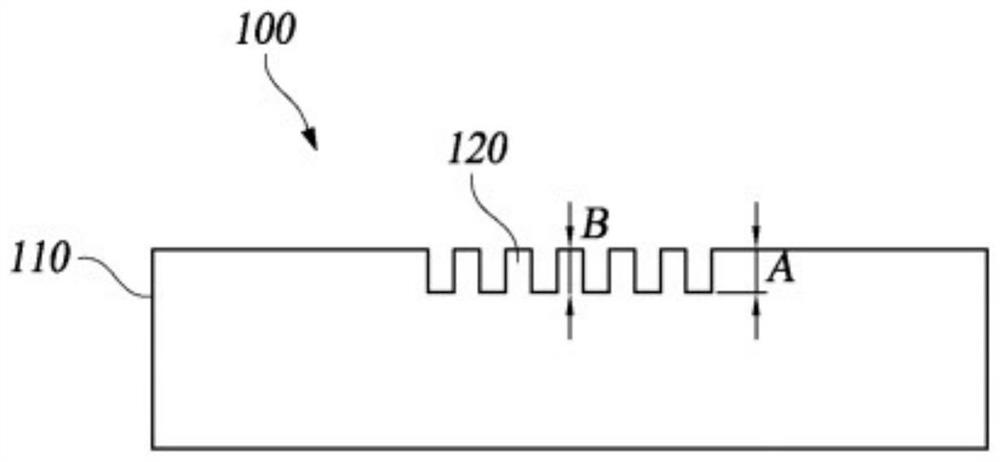

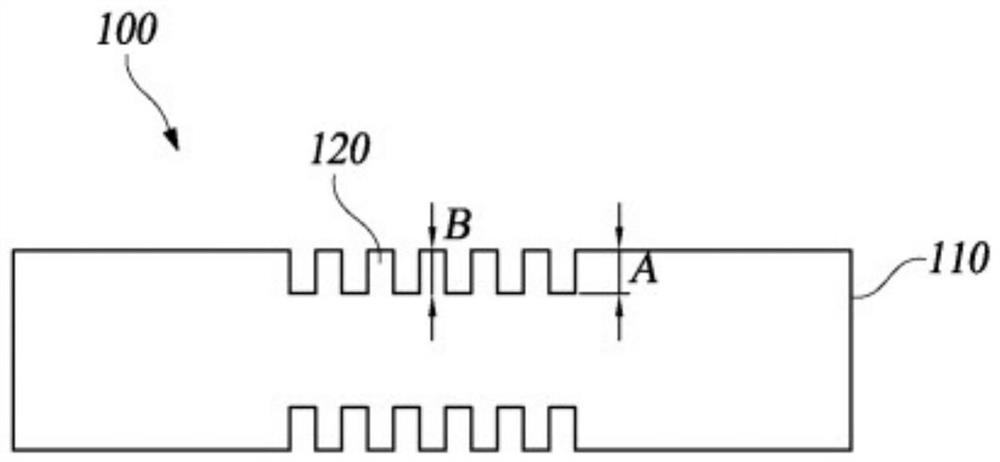

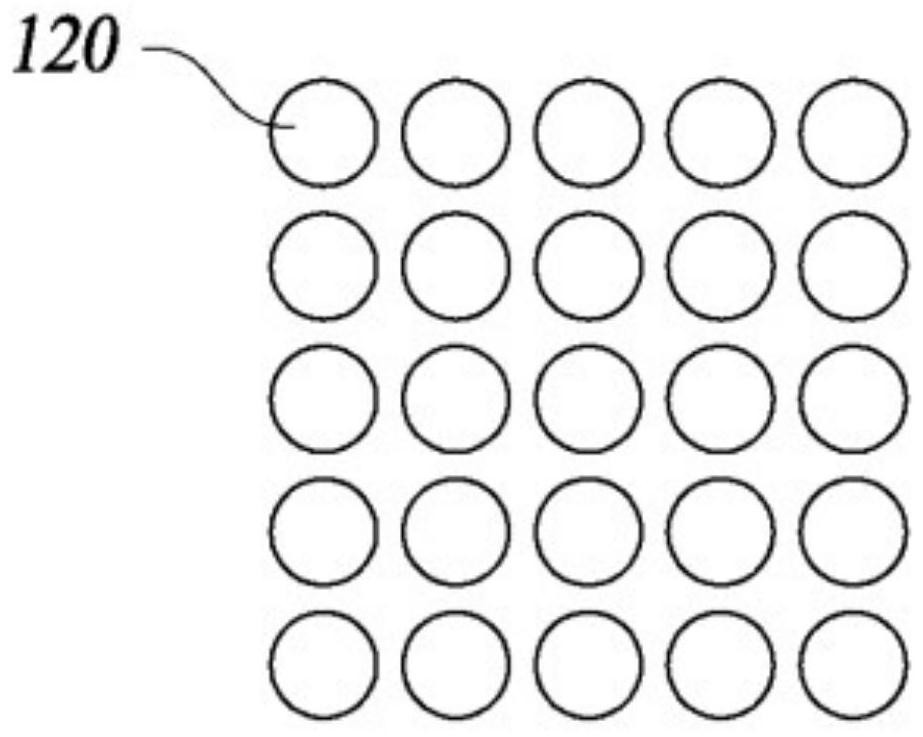

[0053] The present invention relates to a flexible cover window, and more particularly, to a flexible cover window in which a pattern portion for impact compensation is formed on a glass substrate to disperse impact force and improve impact resistance, thereby securing strength characteristics and folding characteristics, and the same Manufacturing method.

[0054] That is, by forming the impact-compensating pattern portion on the folded portion of the glass substrate, the impact is dispersed between the patterns when the pen is impacted, thereby improving rigidity against pen-down and satisfying both the strength characteristic and the folding characteristic.

[0055] Hereinafter, the present invention will be described in detail with reference to the drawings. Figure 1A is a schematic cross-sectional view of a case where a pattern portion for impact compensation is formed on one side of a folded portion according to an embodiment of the present invention, Figure 1B is a sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap