Joining a laminated core to a shaft

A lamination and lamination group technology, applied in the direction of magnetic circuit shape/style/structure, electromechanical devices, magnetic circuit rotating parts, etc., can solve problems such as adhesive durability limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

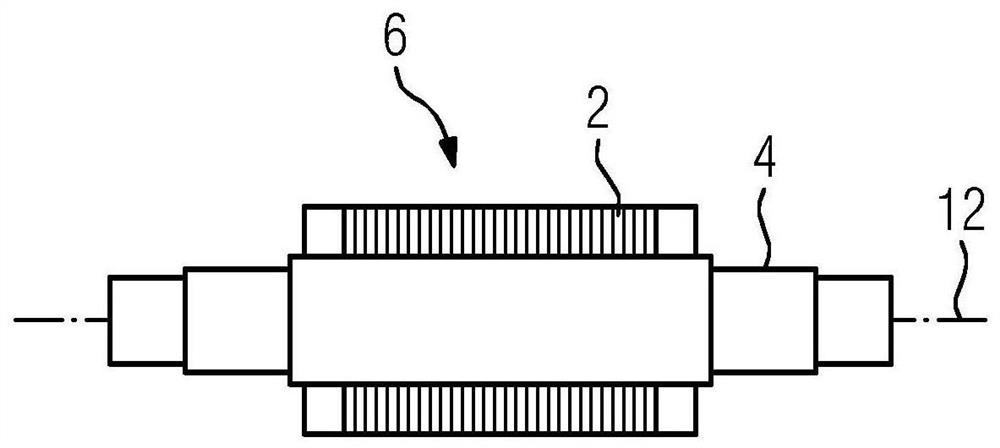

[0044] figure 1 In principle, a longitudinal section through a shaft 4 is shown, on which the laminated core 2 of the rotor 6 is positioned. This shows the end state that the builder of the motor strives to achieve between the lamination pack 2 and the shaft, in order to transfer the torque of the motor 24 to the shaft 4 via the rotor 6, or vice versa in the case of a generator lead into the motor.

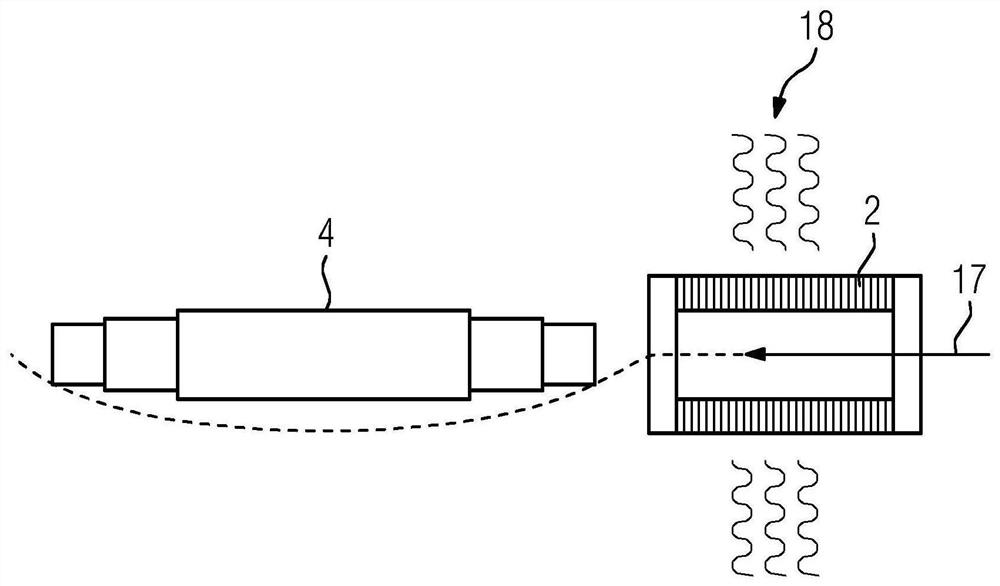

[0045] figure 2 A production method according to the prior art is schematically shown, in which the laminated core 2 is pressed axially onto the shaft 4 by an axial joining force 17 with additional heating 18 of the laminated core 2 . In this case, there is always the risk of buckling of the shaft 4 (indicated by dashed lines) in the event of an excessively high axial joining force 17 . In this case, however, joining force 17 ultimately determines the torsion resistance and torque transmission properties of laminated core 2 and shaft 4 .

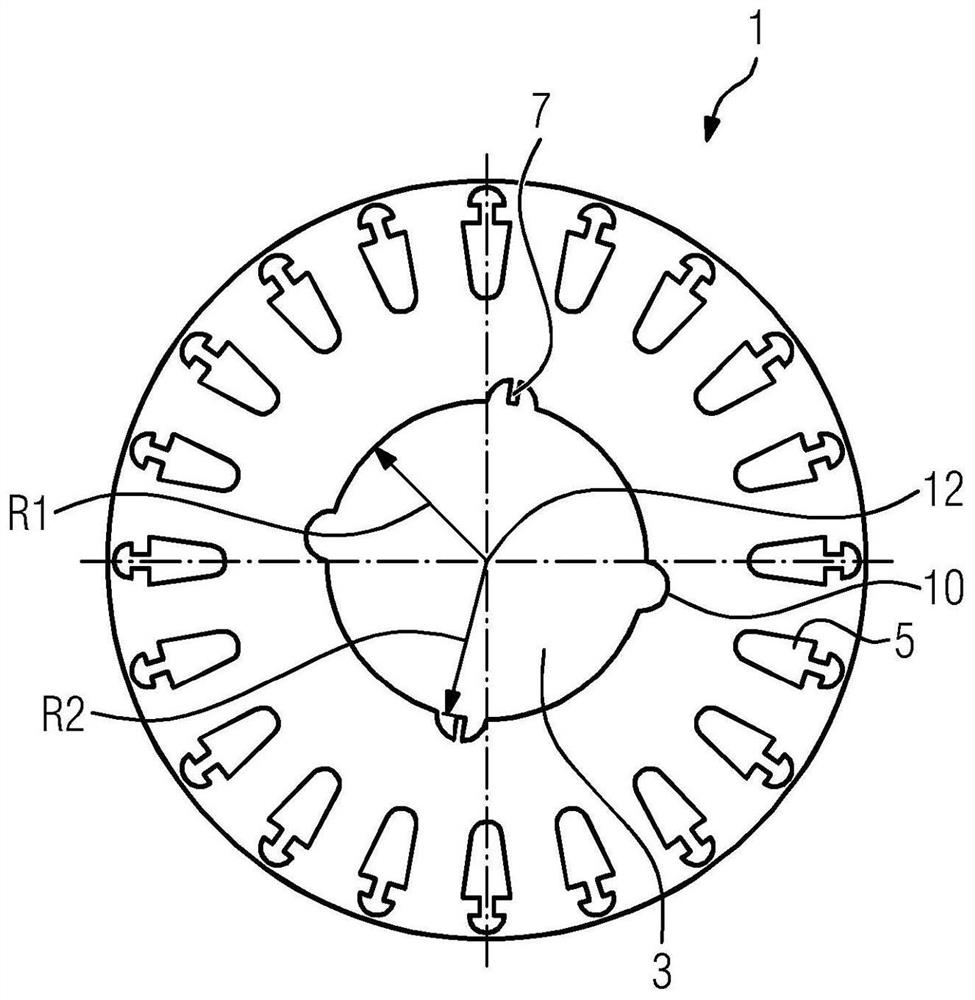

[0046] image 3 The present laminat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com