Steel belt and manufacturing process thereof

A manufacturing process and technology for steel strips, applied in the field of steel strips and their manufacturing processes, can solve problems such as inability to move and punch holes in steel strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention will be further described in detail with reference to the accompanying drawings.

[0031] According to a steel strip manufacturing process of the present invention, the embodiment is combined Figure 1 to Figure 10 shown, where it can be seen that:

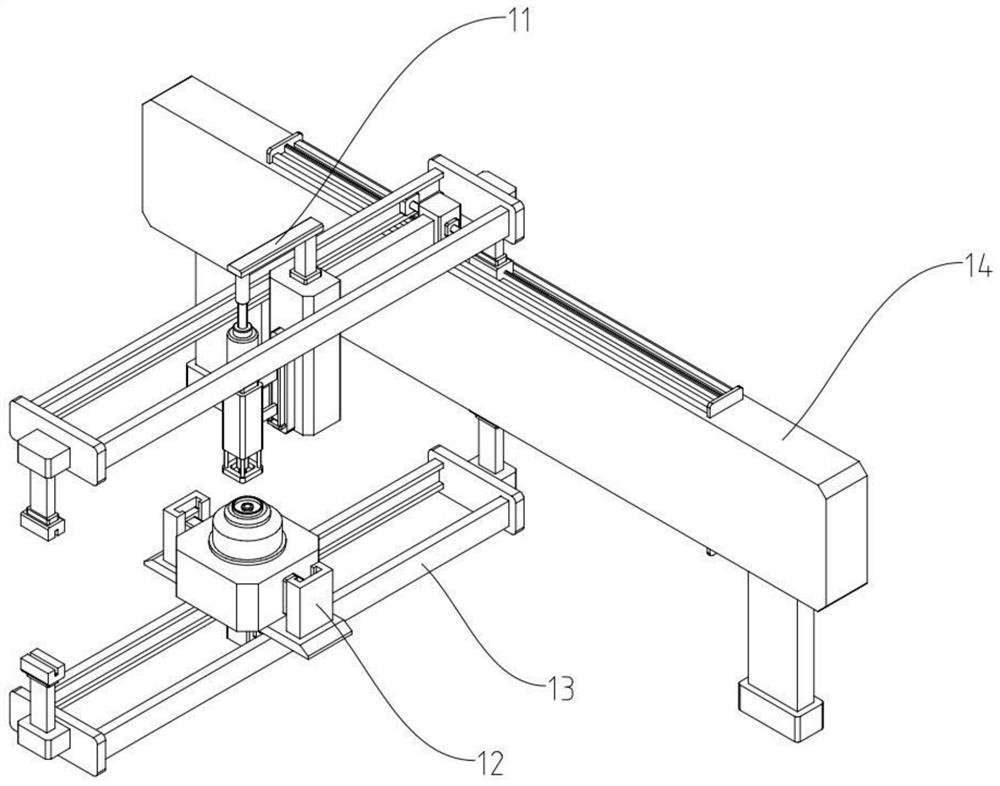

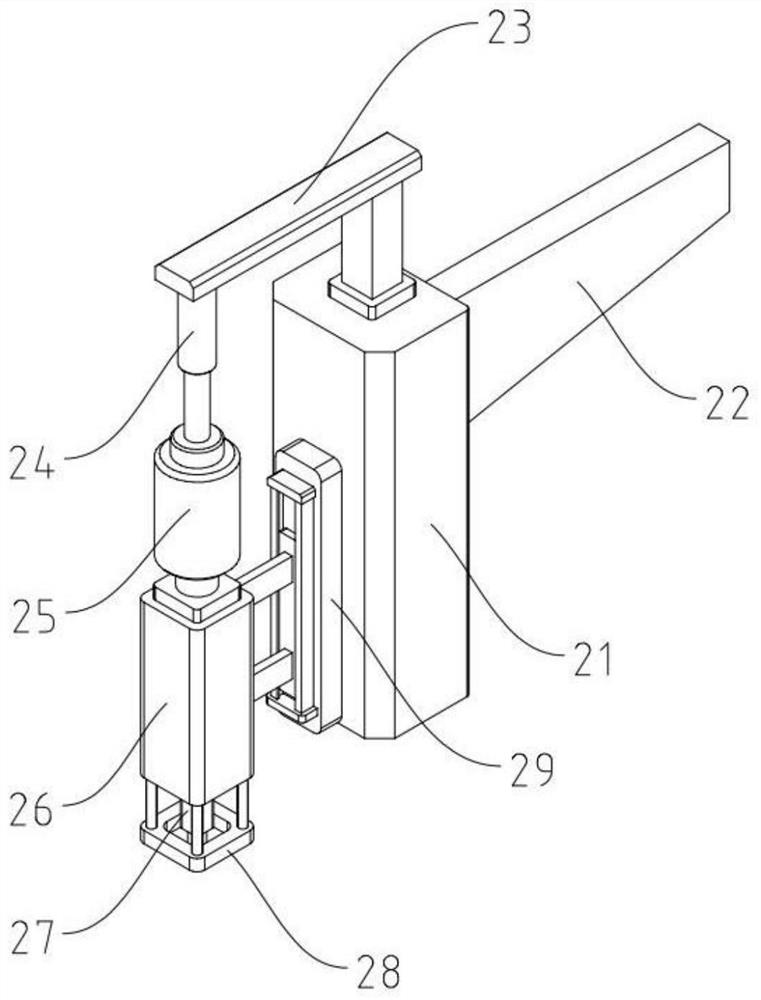

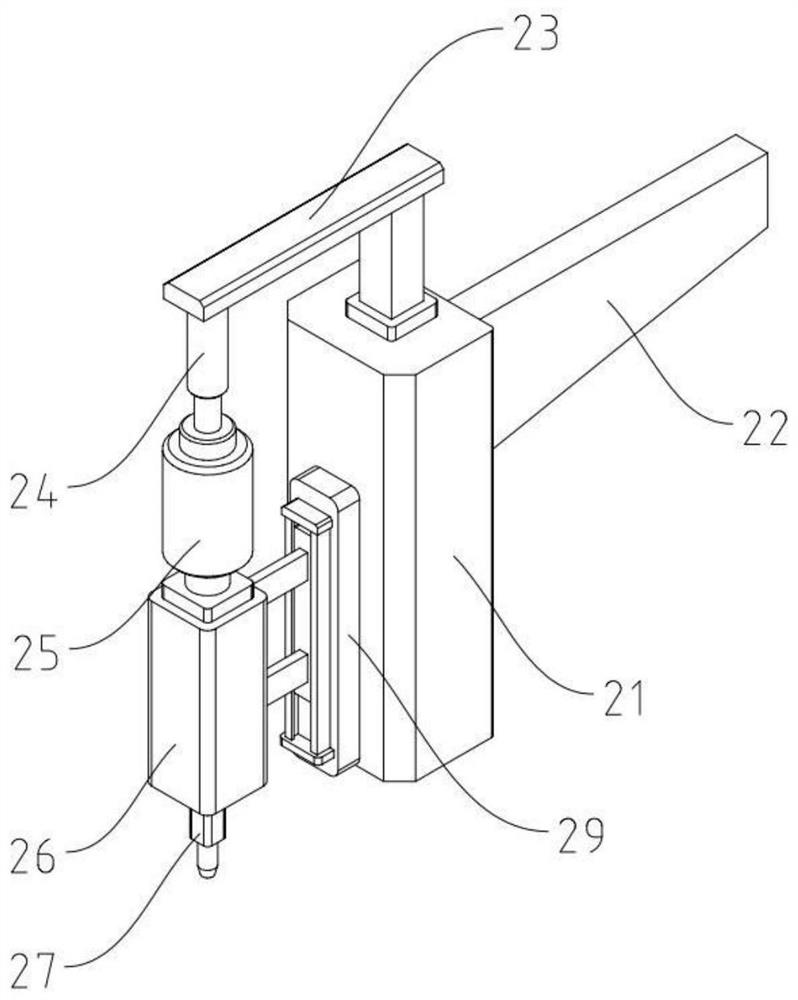

[0032] Attached below figure 1 , 2 , 3, 4, 5, 8, 9 for detailed description. The steel strip manufacturing process can carry out the moving punching work on the steel strip during the normal conveying process of the steel strip without stopping the conveying of the steel strip. The main function realization part of the steel strip manufacturing process includes stamping equipment 11 and stamping die 12 . Wherein the stamping equipment 11 and the stamping die 12 are respectively arranged on two moving traveling structures 13, the stamping equipment 11 and the stamping die 12 are respectively slidingly connected with the two moving traveling structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com