An injection molding processing device for an electric machine permanent magnet

A technology of injection molding and permanent magnets, which is applied in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve the problems of reducing the stability of magnets, affecting the performance of magnets, and uneven magnetic strength of magnets, so as to improve the effect and work The effect of high efficiency and good homogenization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be described clearly and completely below with reference to the accompanying drawings in the embodiments of the present invention.

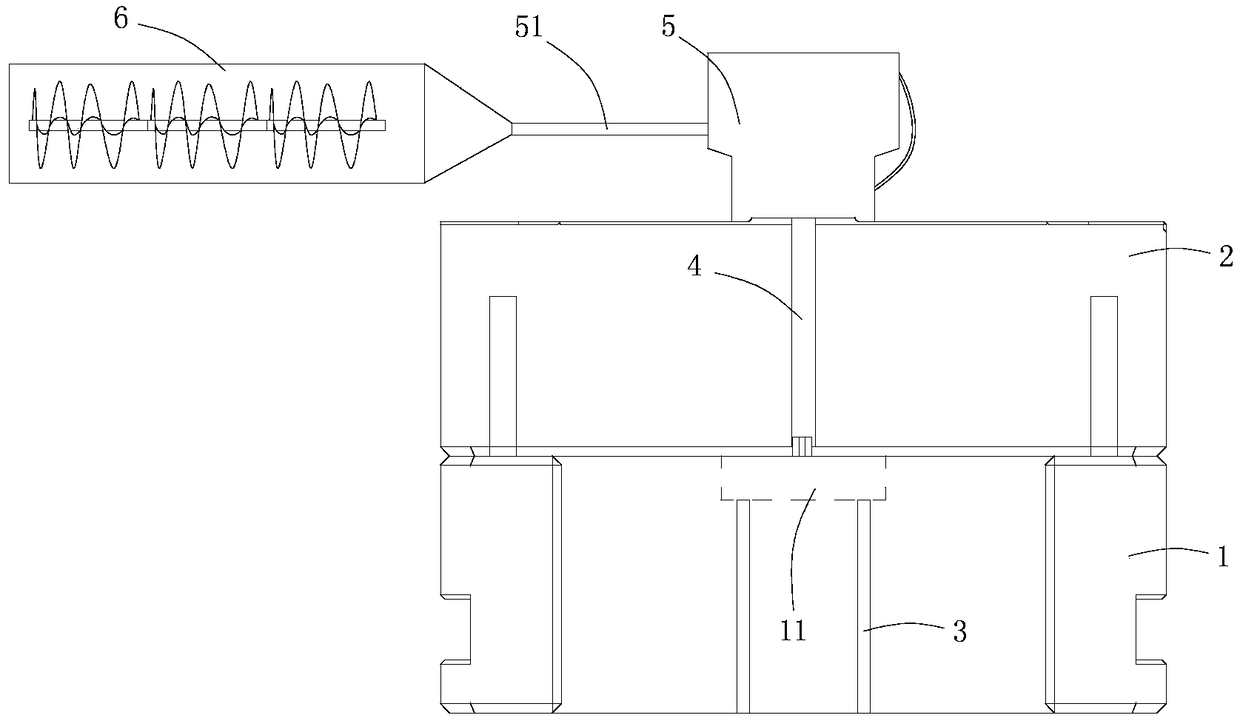

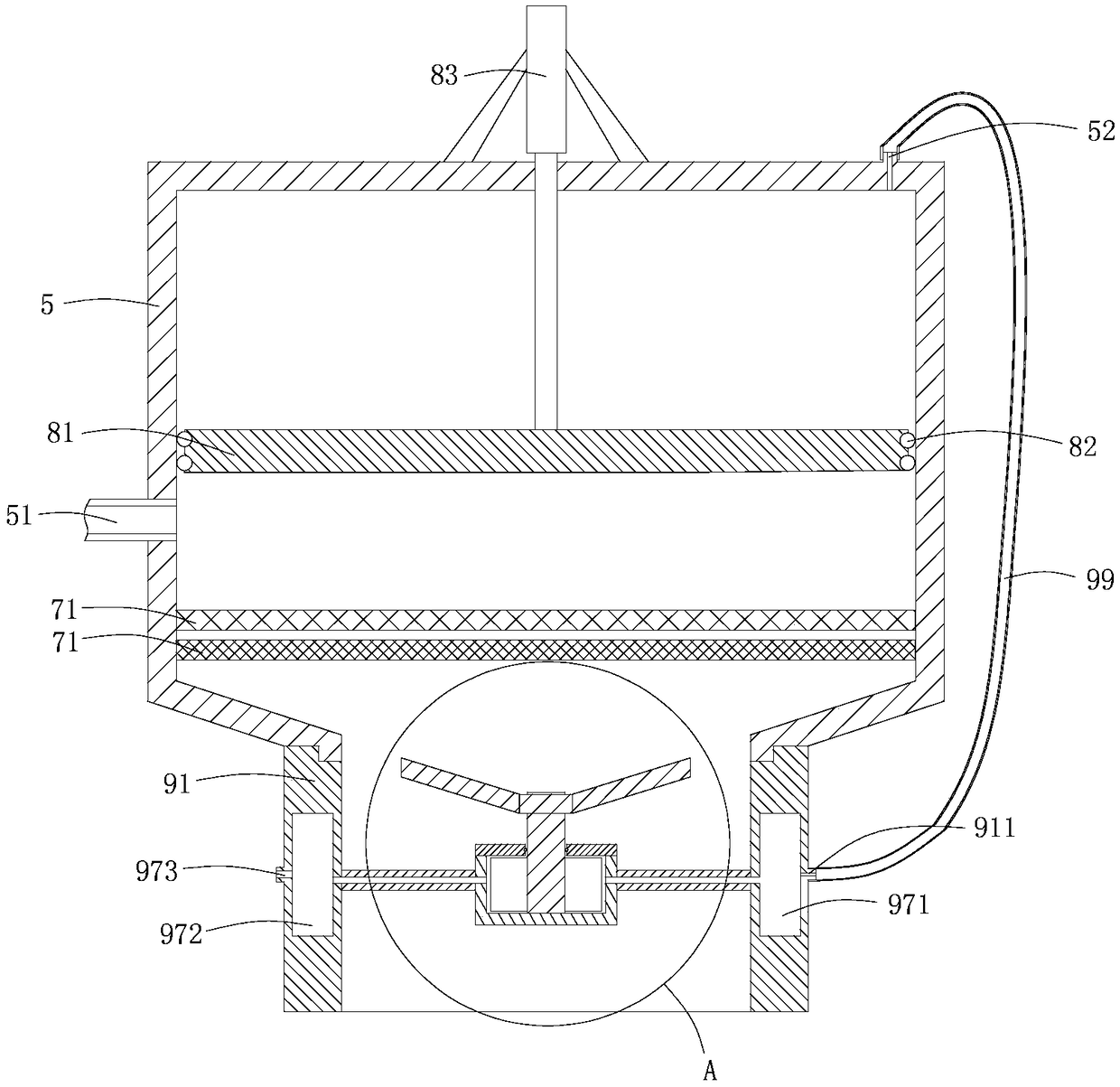

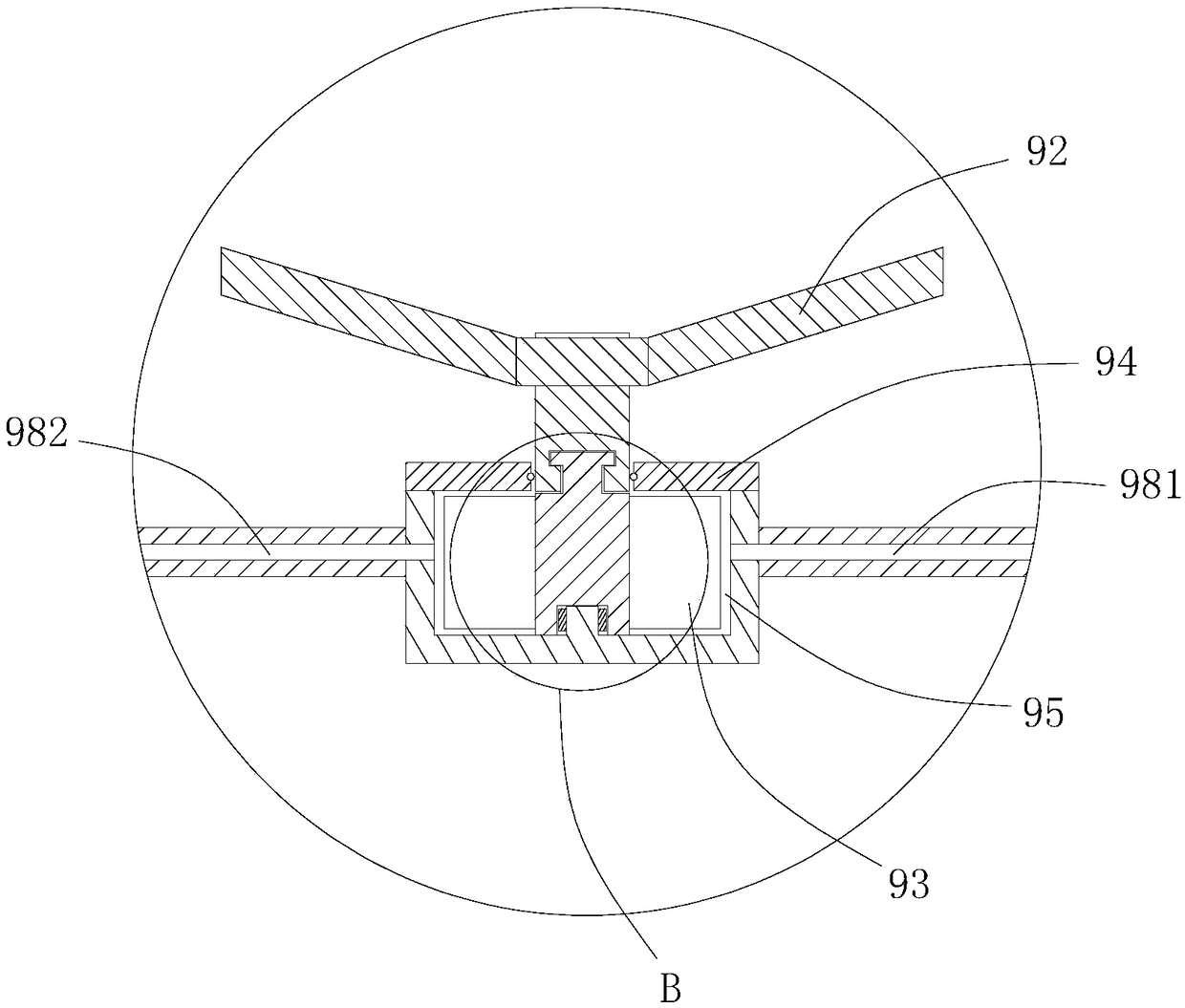

[0029] like Figure 1-5 As shown, an injection molding equipment for motor permanent magnets includes a plasticizing device 6, a lower mold 1, an upper mold 2, an ejector pin 3, an injection channel 4, a material storage chamber 5, an impurity filter device and a turbulence device; the The injection cavity 11 is set on the lower mold, and the specific shape is determined according to the requirements in the actual processing process; there is a mold foot between the upper mold 2 and the lower mold 1, and the mold foot can be driven by a cylinder to realize expansion and contraction, thereby making the upper mold The mold 2 can move up and down relative to the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com