Cutting tool convenient to replace and used for machining of numerical control machine tool

A technology that is convenient for replacement and CNC machine tools, applied in the field of CNC machine tools, can solve the problems of low efficiency of milling cutter replacement and complicated installation and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

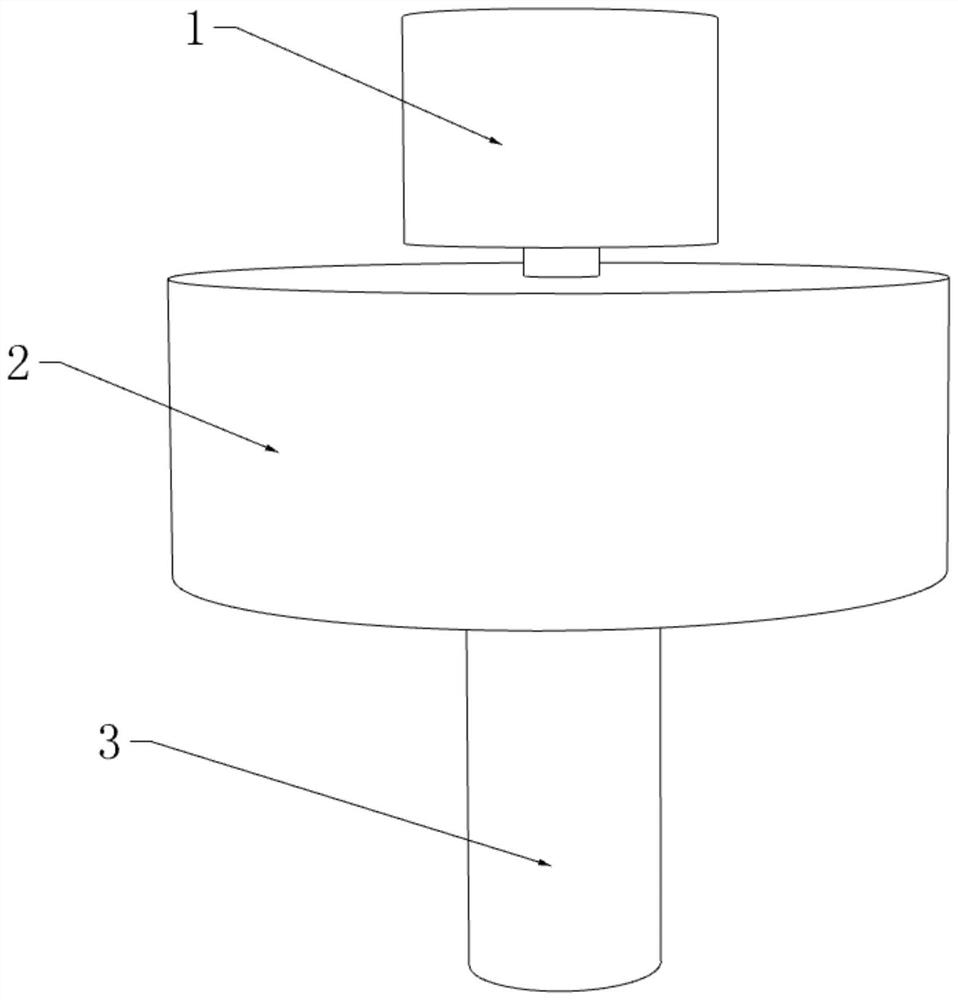

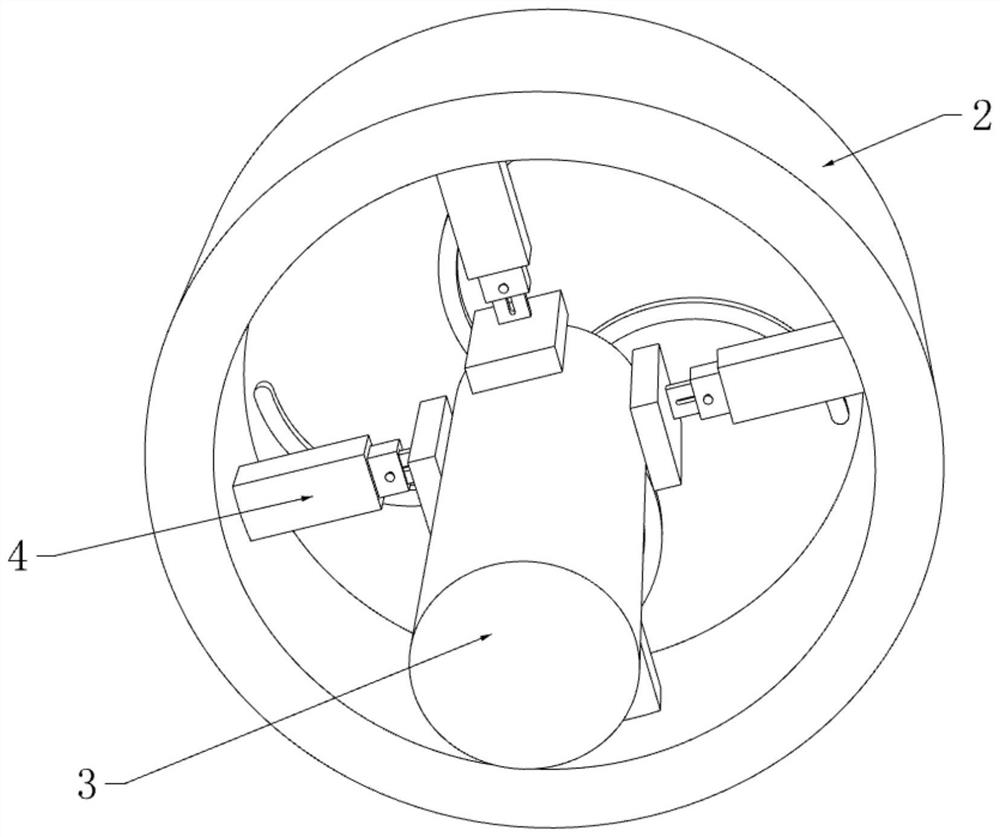

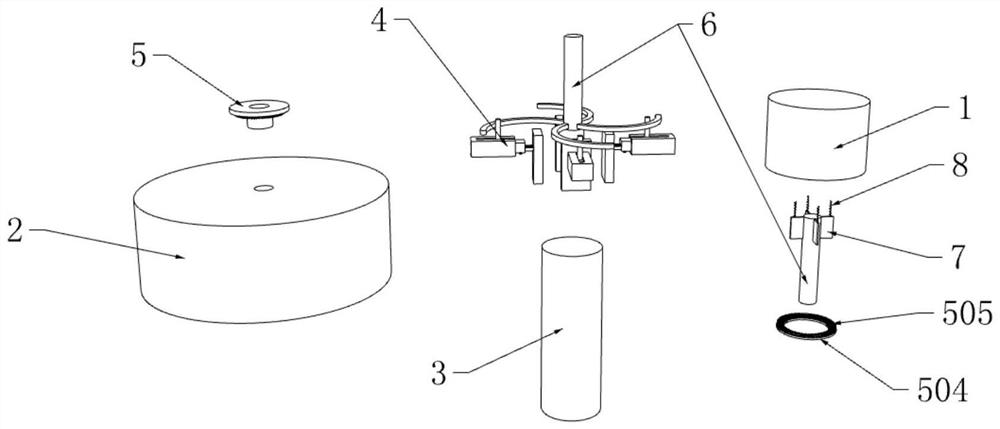

[0035] refer to figure 1 , figure 2 and Figure 8 , a cutting tool that is conveniently replaced for CNC machine tool processing, including an adjusting cap 1, a mounting part 2 and a milling cutter mounting head 3, the adjusting cap 1 and the mounting part 2 are both arranged in a hollow structure, and the bottom end is provided with an opening for milling The knife installation head 3 is installed inside the installation part 2 .

[0036] refer to image 3 and Figure 8 , the inside of the adjustment cap 1 is provided with a mounting groove 102, and the inside of the adjustment cap 1 is provided with a limit groove 101 distributed in an annular array around the installation groove 102, and the drive rod 6 is slidably installed inside the installation groove 102, and the drive rod 6 The rod body of the rod body is fixedly connected with a limiting plate 7 in a circular array and corresponding to the limiting groove 101. The end of the driving rod 6 extends to the inside ...

Embodiment 2

[0042] refer to Figure 6 , Figure 7 and Figure 9-11 One end of the third mounting plate 405 is slidably installed inside the second mounting plate 404, the top inner wall of the second mounting plate 404 is provided with a movable groove 4012, and the movable plate 408 is slidably installed inside the movable groove 4012, and the movable groove 4012 The first return spring 409 distributed in a rectangular array is fixedly connected between the top inner wall and the top of the movable plate 408, and the bottom end of the movable plate 408 is fixedly connected with a push rod 407, and the push rod 407 slides through the third mounting plate 405 and the first mounting plate 405. The bottom side walls of the second mounting plate 404 extend to the bottom of the second mounting plate 404 and are fixedly connected with an anti-off block. The bottom of the movable plate 408 is equipped with two groups of first positioning teeth 4010 that are symmetrically distributed. Two sets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com