A grinding machine tool for inner wall of square tube port

A grinding and machine tool technology, which is applied in the field of grinding machine tools for the inner and side walls of square tube ports, which can solve the problems of easily scratched staff and inability to realize automatic blanking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

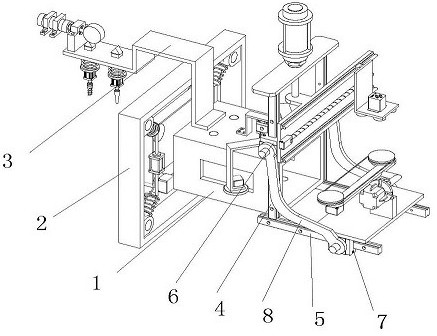

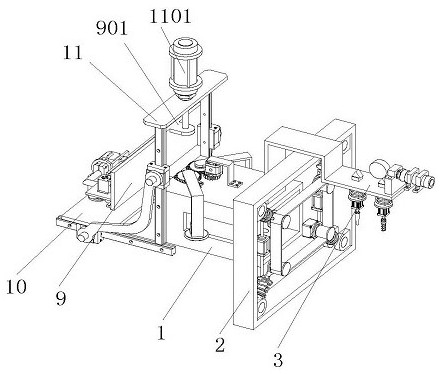

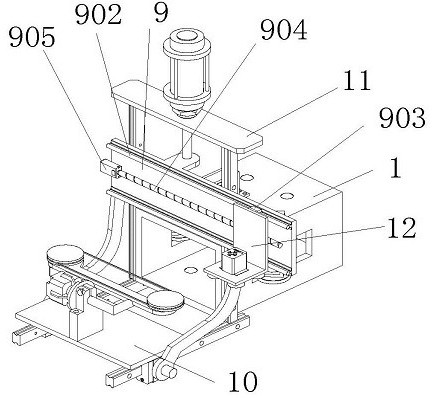

[0032] In order to make the objectives, technical solutions and advantages of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described herein are merely intended to illustrate the invention and are not intended to limit the invention.

[0033] In the description of the present invention, it is to be understood that the term "longitudinal", "horizontal", "upper", "lower", "front", "post", "left", "right", "vertical", The orientation relationship between "horizontal", "top", "bottom", "inside", "outside", etc. is based on the orientation or positional relationship shown in the drawings, but is intended to facilitate the description of the present invention, not an indication or I suggest that the device or component must have a specific orientation, constructed and operated in a particular direction, and thus is not to be construed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com