Paper connecting machine and braking system thereof

A braking system and paper splicing machine technology, applied in manufacturing tools, ceramic forming machines, auxiliary forming equipment, etc., can solve the problems of replacing paper rolls and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

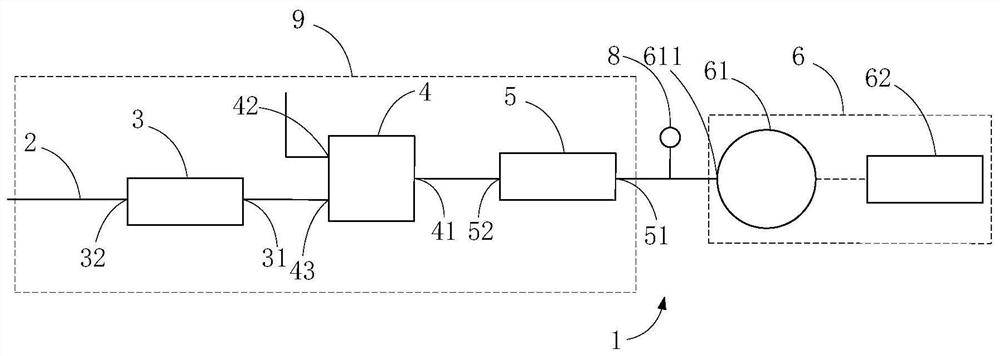

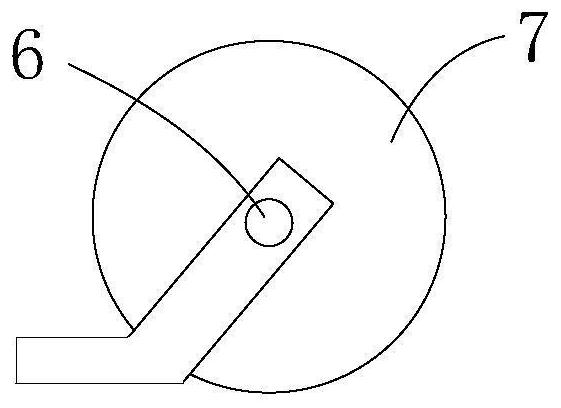

[0030] Such as figure 1 as shown, figure 1 The braking system 1 of the splicer in this embodiment is shown. The brake system 1 is installed on the paper splicer. The braking system 1 is used for braking the replacement paper roll 7 on the splicer. The braking system 1 includes a pneumatic brake 6, a pressure sensor 8, a driving assembly 9 and a controller. The controller is electrically connected to the drive assembly 9 . The drive assembly 9 is connected to the pneumatic brake 6 . Such as figure 2 As shown, the pneumatic brake 6 can be arranged at one end of the rotating shaft of the paper roll 7 . The pneumatic brake 6 can apply resistance to the rotation of the paper roll 7 to tension and straighten the paper tape output by the paper roll 7 . The driving assembly 9 provides driving force for the operation of the pneumatic brake 6, and the power provided by the driving assembly 9 is controlled by the controller.

[0031] The pneumatic brake 6 may be a normally open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com