Novel demulsification method for crude oil produced liquid

A technology for producing fluid and demulsification, which is applied in the fields of chemical dehydration/demulsification, petroleum industry, processing of hydrocarbon oil, etc., and can solve the problem of less improvement in process methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Preparation of emulsified crude oil: When the time interval between crude oil production and liquid sampling is long, the mixed sample of crude oil and water will be separated for a long time. Use a four-bladed stirring rod at 550r / min, 45°C water bath, and mechanically stir for 40 minutes to make the crude oil Re-emulsify, and then carry out the demulsification test.

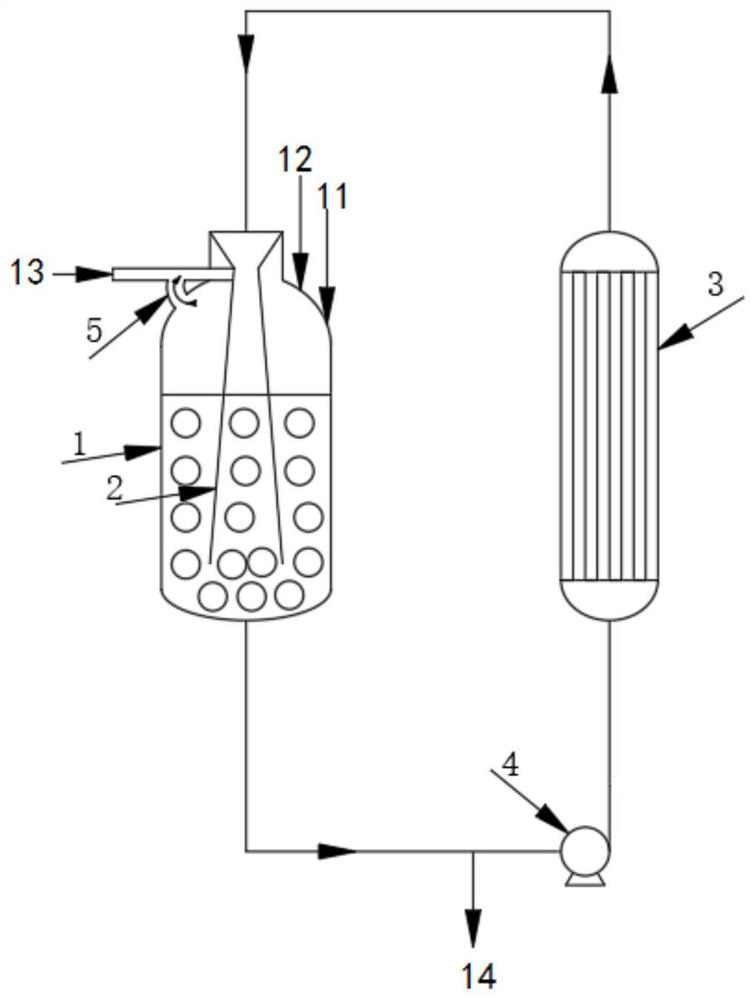

[0029] Demulsification experiment of the present invention: a certain amount of re-emulsified crude oil (or directly extracted crude oil production fluid), a certain amount of demulsifier through the feed port (demulsifier feed port 11 and crude oil production fluid feed Port 12) into the reaction kettle, turn on the circulation pump 4 to make the liquid in the kettle flow slowly, the liquid material is kept at a certain temperature through the temperature control of the heat exchanger, fill in the process gas to the system pressure of 1MPa and then empty it, repeat the reaction of the replacement injecti...

Embodiment 1

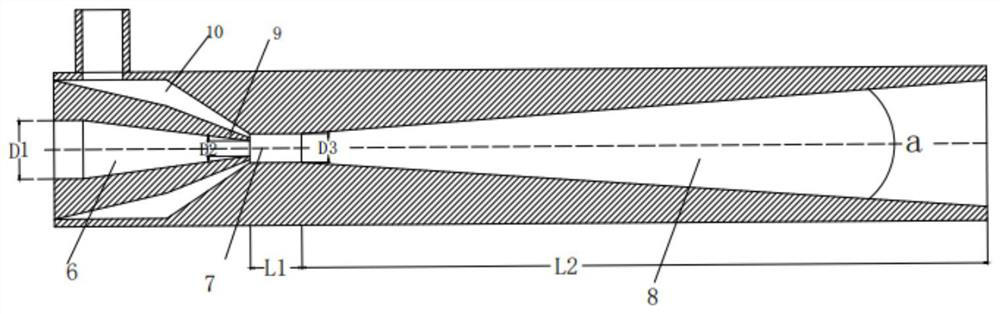

[0036] The ratio of opening diameter D1 of inlet section of Venturi injector used in this example: inner diameter of nozzle D2: inner diameter of air chamber closing D3: length of mixing section L1: length of diffusing section L2 is 38:3:4:350 : 1500, the opening angle of the diffusion section is 10°.

[0037] Preparation of emulsified crude oil: Due to the long time interval from sampling time, the mixed sample of crude oil and water has been placed for a long time to stratify. Use a four-bladed stirring rod at 550r / min, 45°C water bath, and mechanically stir for 40 minutes to re-emulsify the crude oil, and then carry out Demulsification experiment as follows.

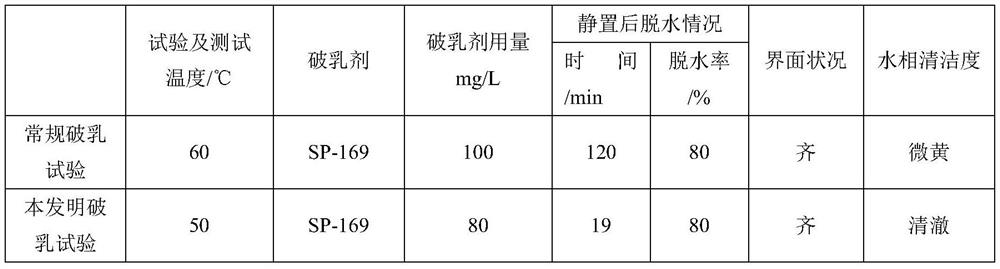

[0038] Demulsification experiment of the present invention: add a certain amount of re-emulsified crude oil, a certain amount of demulsifier (SP-169, consumption is 80mg / L) in the reaction kettle through the feed port, open the circulation pump 4 to make the liquid in the kettle Flow slowly, the liquid material is co...

Embodiment 2

[0044] The ratio of the opening diameter D1 of the inlet section of the venturi injector used in this example: the inner diameter of the nozzle D2: the inner diameter of the gas chamber closing D3: the length of the mixing section L1: the length of the diffusion section L2 The ratio is 38:3.5:5:220 : 1150, the opening angle of the diffusion section is 4°.

[0045] Demulsification experiment of the present invention: add the freshly produced crude oil production fluid and a certain amount of demulsifier (AE8051, the dosage is 75mg / L) into the reaction kettle through the feed port, and turn on the circulation pump 4 to make the liquid in the kettle flow slowly , the liquid material is controlled by a heat exchanger to maintain a temperature of 45 ° C, filled with methane gas to a system pressure of 1 MPa, and then vented, and repeated 3 times to replace the air in the jet loop reactor. After the last replacement, keep the pressure of the reaction system to the demulsification pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com