A variable temperature indoor hot water heating radiator

A heat sink and temperature type technology, applied in the field of variable temperature indoor hot water heating radiators, can solve the problems of uncontrollable speed and flow of hot water, insufficient release of hot water heat energy, increased workload of hot water pumps, etc. Reach the effects of caliber size affecting sensitivity, improving deformation sensitivity and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

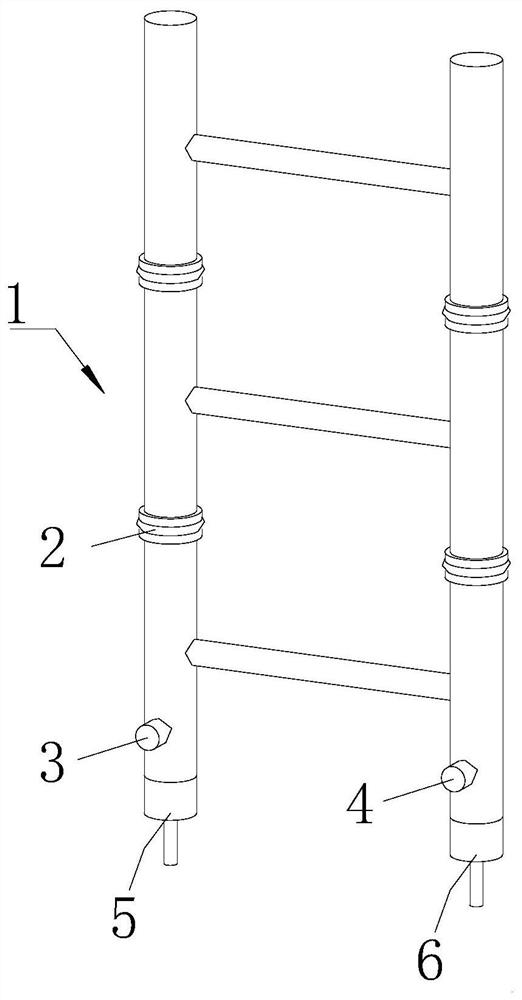

[0040] Specific embodiment one: please refer to Figure 1-6 A temperature-variable indoor hot water heating radiator includes a cooling assembly 1 , a water inlet 3 , a water outlet 4 , a water inlet control assembly 7 and an outlet water control assembly 8 .

[0041] The water inlet 3 supplies water to the cooling assembly 1 .

[0042] The water outlet 4 drains water for the cooling assembly 1 .

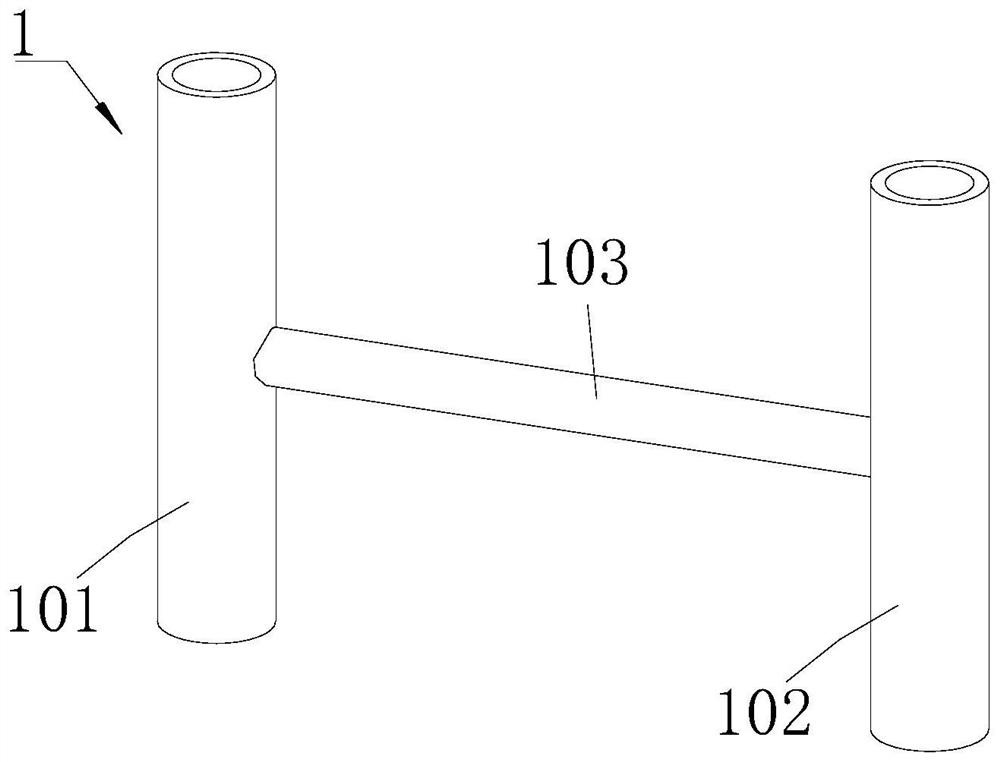

[0043] The heat dissipation assembly 1 includes an upper return pipe 101 , a lower return pipe 102 and a heat dissipation pipe 103 .

[0044] The upper whirling pipe 101 communicates with the lower whirling pipe 102 through a cooling pipe 103 .

[0045] There are multiple heat dissipation components 1 , and the plurality of heat dissipation components 1 are distributed from top to bottom and connected end to end, two adjacent upper return pipes 101 are connected, and two adjacent lower return pipes 102 are connected.

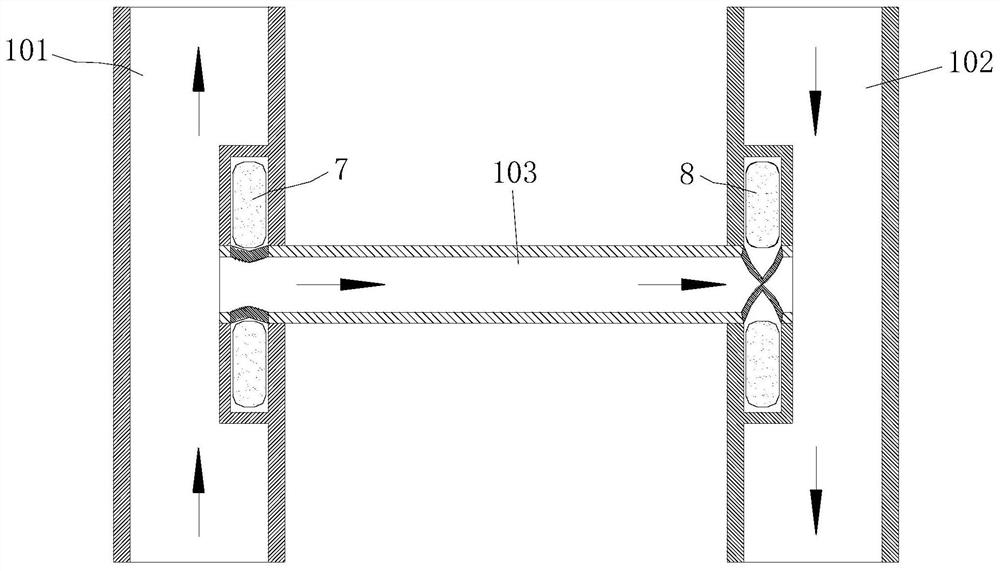

[0046] The water inflow control assembly 7 includes a water i...

specific Embodiment 2

[0060] Specific embodiment two: please refer to Figure 7-8 A temperature-variable indoor hot water heating radiator is different from the specific embodiment 1 in that the side wall of the upper pipe 101 is provided with a water inlet. A plurality of water inlet airbags 701 are uniformly arranged around the water inlet. The water inlet membrane 703 is fixed inside the water inlet air bag 701 . The cooling pipe 103 is detachably connected to the outer end of the upper turning pipe 101, and the upper turning pipe 101 communicates with the cooling pipe 103 through a water inlet.

[0061] The side wall of the lower whirling pipe 102 is provided with a water outlet. A plurality of water outlet airbags 801 are uniformly arranged around the water outlet. The water outlet diaphragm 803 is fixed inside the water outlet air bag 801 . The heat dissipation pipe 103 is detachably connected to the outer end of the lower return pipe 102, and the lower return pipe 102 communicates with t...

specific Embodiment 3

[0063] Specific embodiment three: please refer to Figure 9 A variable temperature indoor hot water heating radiator, on the basis of the specific embodiment 1, the inner wall of the downpipe 102 is fixed with an acceleration bump 804 . The acceleration bump 804 is located on the inner wall of the lower turning pipe 102 at the same height as the communication port between the cooling pipe 103 and the lower turning pipe 102 . When the hot water in the downpipe 102 is discharged from top to bottom, the caliber suddenly becomes smaller, the flow rate of the hot water suddenly increases, and the water pressure suddenly decreases, so that the hot water in the cooling pipe 103 tends to move down the downpipe 102 .

[0064] The diameters of the acceleration bumps 804 in each heat dissipation assembly 1 are different, and the diameters of the acceleration bumps 804 gradually increase from high to low according to the horizontal height, so that the lower the heat dissipation assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com