Device for measuring steel wire position of slicing machine

A slicer and steel wire technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of increased product scrap rate, economic loss, and inability to determine whether it meets the best cutting state, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

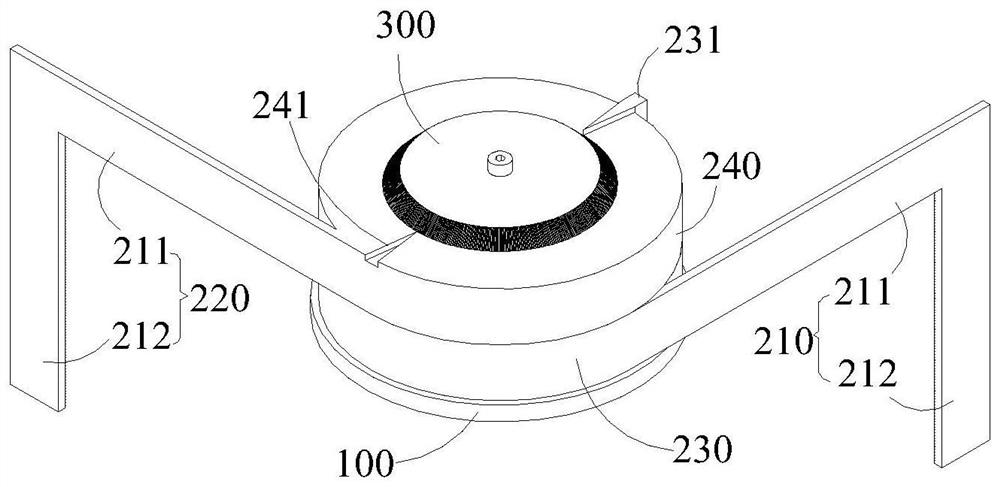

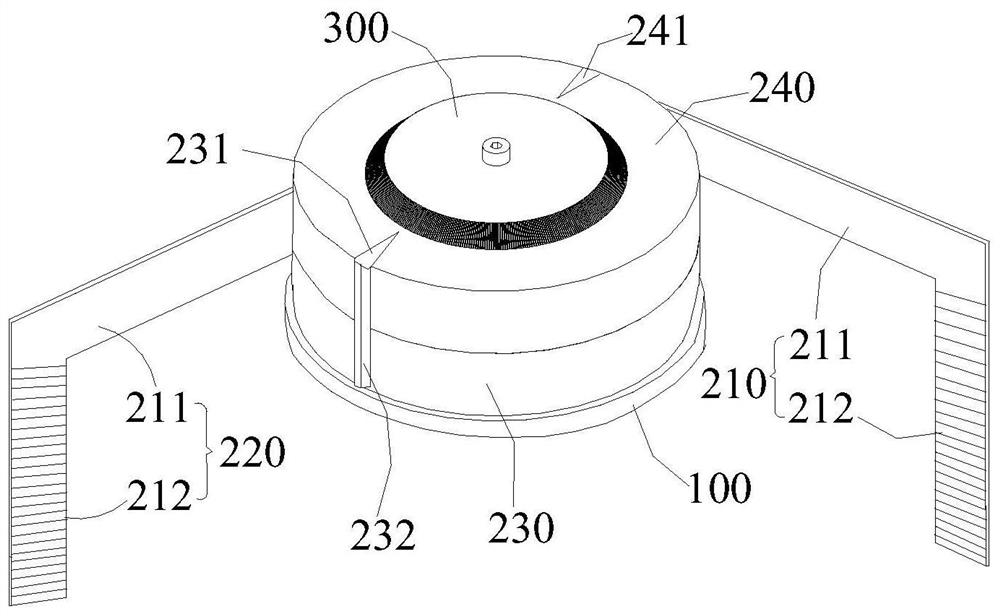

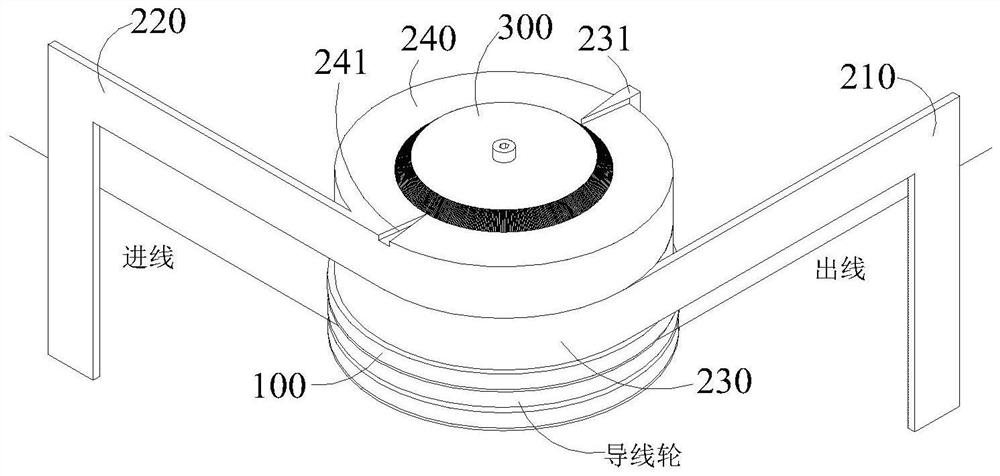

[0041] (1) Measure the angle between the incoming and outgoing wires of the steel wire and adjust the angle between the incoming and outgoing wires to the best state, please refer to Figure 1 to Figure 8 , the specific operation is: the device is installed on the guide wheel, so that the vertical arm 212 of the first measuring arm 210 and the vertical arm 212 of the second measuring arm 220 are respectively attached to the outgoing line and the incoming line of the steel wire, from the dial 300 Read the scales pointed to by the first indicator needle 231 and the second indicator needle 241 respectively. If the absolute value of the scale difference between the indicator needles is 180°, the angle between the incoming line and the outgoing line is 90°. If indicated If the angle between the needles is not 180°, you need to adjust the position of the guide wheel until the angle between the first indicator needle 231 and the second indicator needle 241 is 180°, then the angle betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com