Thrust small fillet measuring tool convenient to position

A measurement tool and small fillet technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of measurement result influence, small scope of application, and poor positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

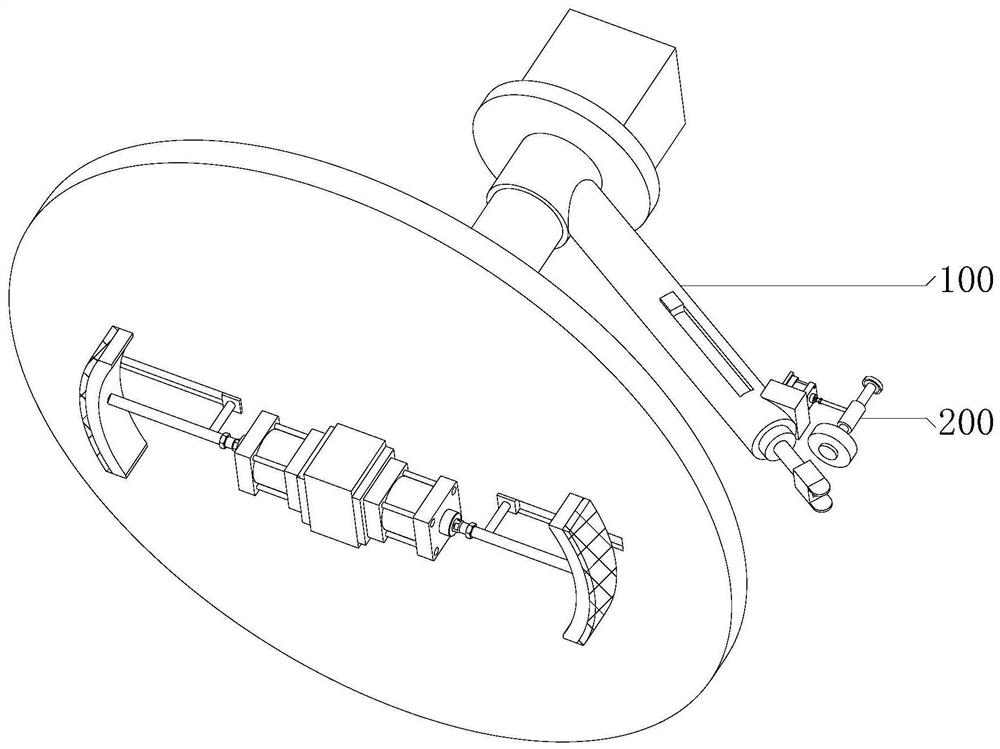

[0034] see Figure 1-5 , the present invention provides a technical solution: a conveniently positioned thrust small fillet measuring tool, including a base mechanism 100 and a positioning mechanism 200, the positioning mechanism 200 is arranged on the base mechanism 100, and is used to make the base mechanism 100 and the shaft cover Relatively fixed, the precise positioning of the basic mechanism 100 is realized, and the influence of the inaccurate positioning of the basic mechanism 100 on the detection results is avoided.

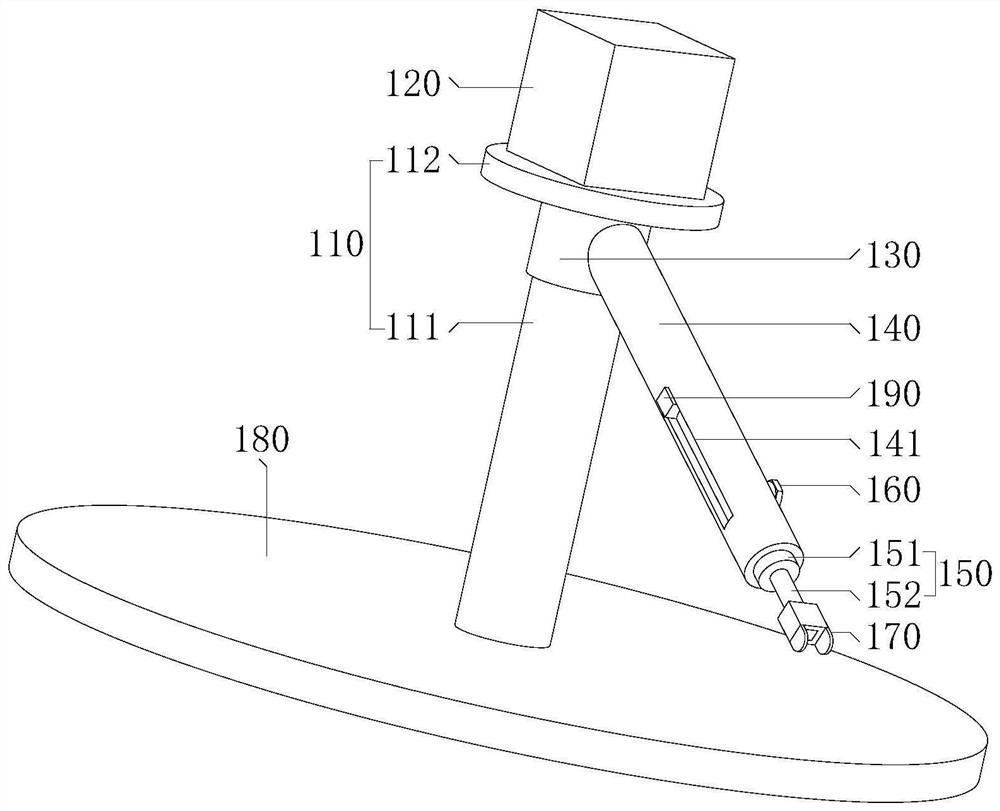

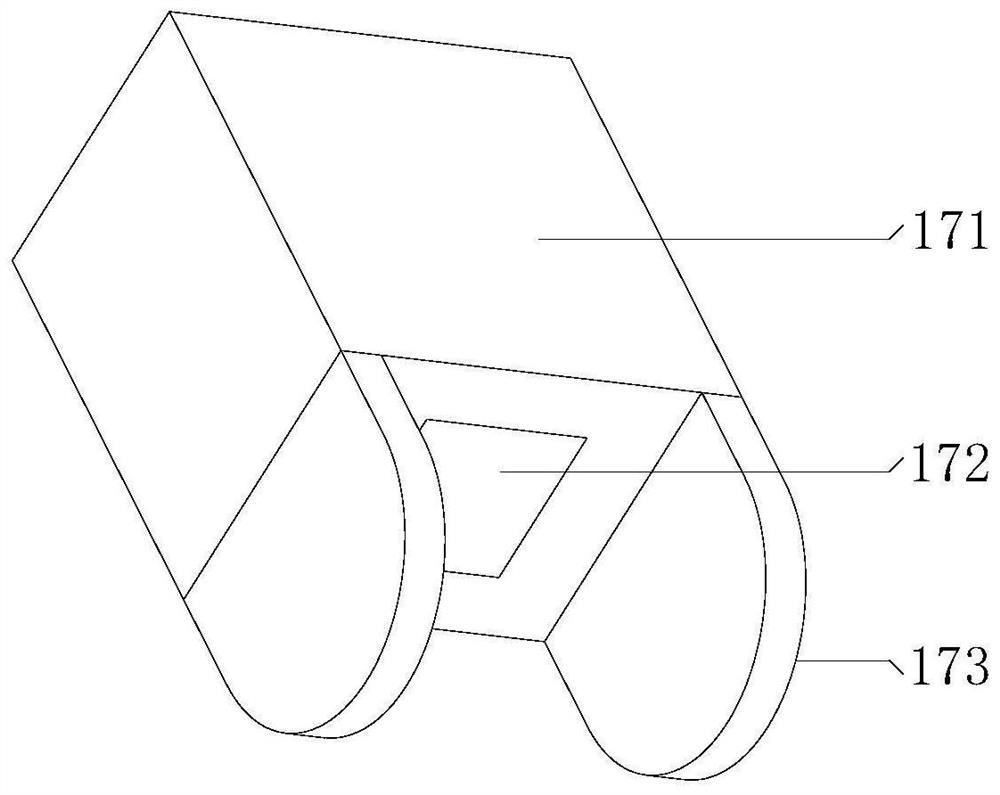

[0035] see figure 2 and image 3 , the basic mechanism 100 includes a connecting column 110, a chassis 180, a display module 120, a collar 130, a sleeve 140, a sliding rod 150, a first slider 190, a locking member 160 and a measuring assembly 170, and the connecting column 110 includes a column body 111 and the top plate 112, the top plate 112 is fixed on the top of the column 111, the middle part of the upper surface of the chassis 180 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com