Accurate measurement device and method for loading force of ultralow-temperature equipment

A technology of precise measurement and loading device, applied in measurement device, using stable tension/pressure test material strength, mechanical bearing test, etc., can solve the problems of large heating temperature control temperature drift error and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

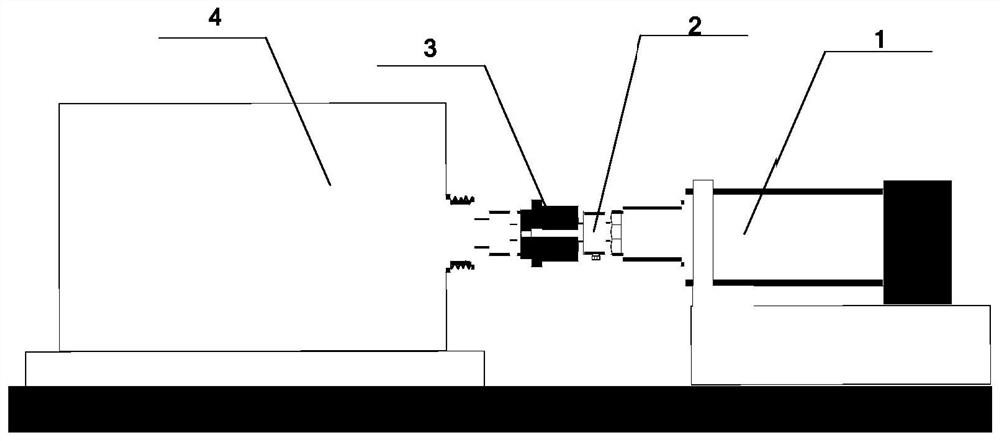

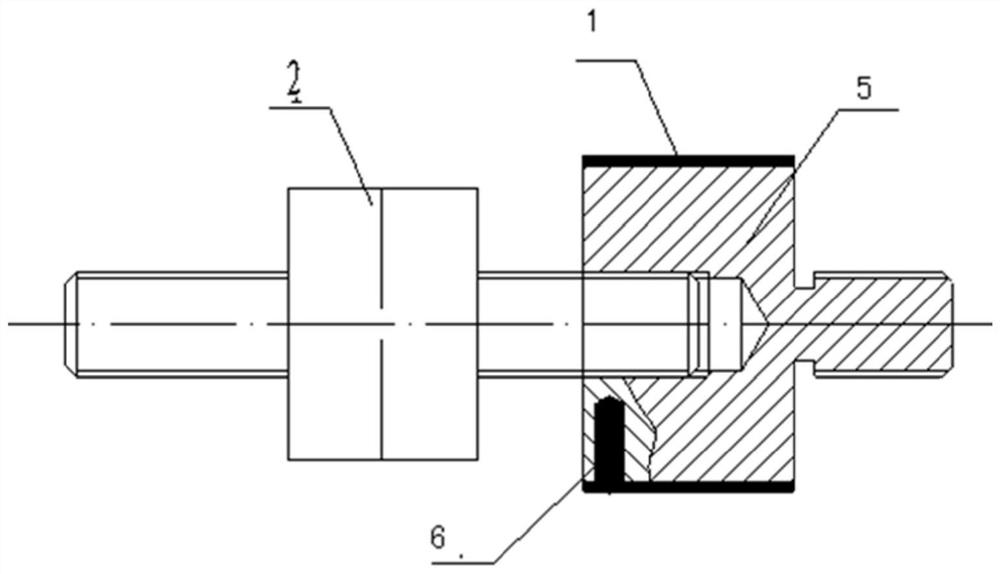

[0026] An accurate measurement device for the loading force of ultra-low temperature equipment, which can highly simulate the test environment and the environment when the force sensor is sent for inspection, and keep it relatively consistent. It can basically solve the problem of temperature drift in low temperature measurement and prolong the working life of the force sensor. Specifically:

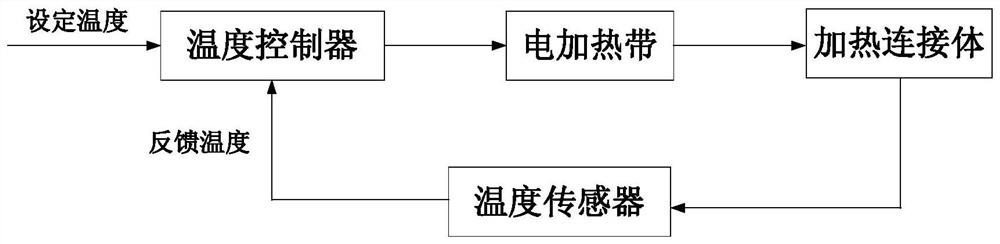

[0027] The output end of the loading device used to provide the loading force provides the loading force for the equipment to be loaded through the force sensor and the loading connector. One end of the force sensor is connected to the output end of the loading device, and the other end is connected to the loading connector to measure the loading force. The outside of the loading connector is coated with an electric heating belt that provides a working temperature environment for the force sensor, and a temperature sensor that monitors the temperature of the force sensor in real time is em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com