Folding insertion piece type battery and manufacturing process thereof

A manufacturing process and inserting technology, which is applied in the field of folded inserting battery and its manufacturing process, which can solve the problems of battery short circuit, dust piercing the diaphragm, easy powder falling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

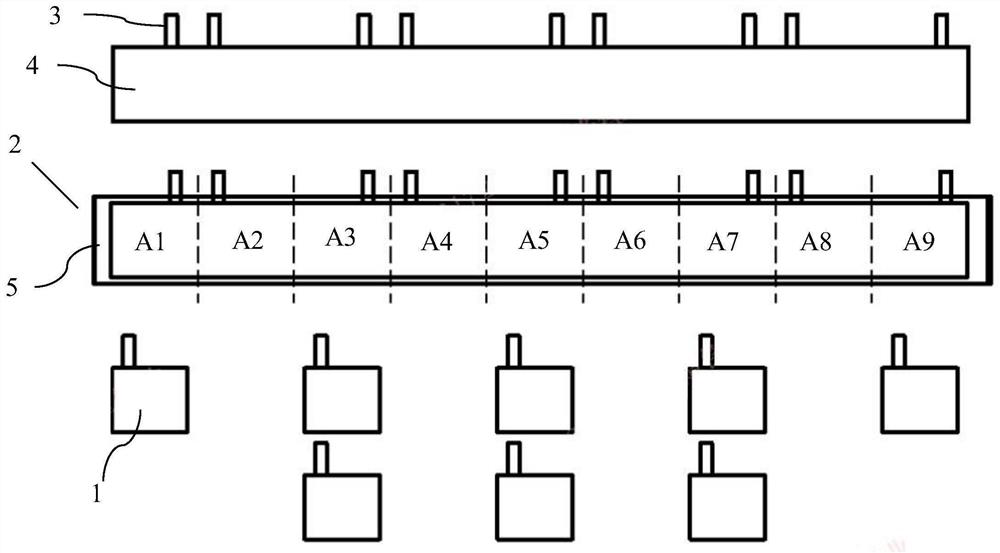

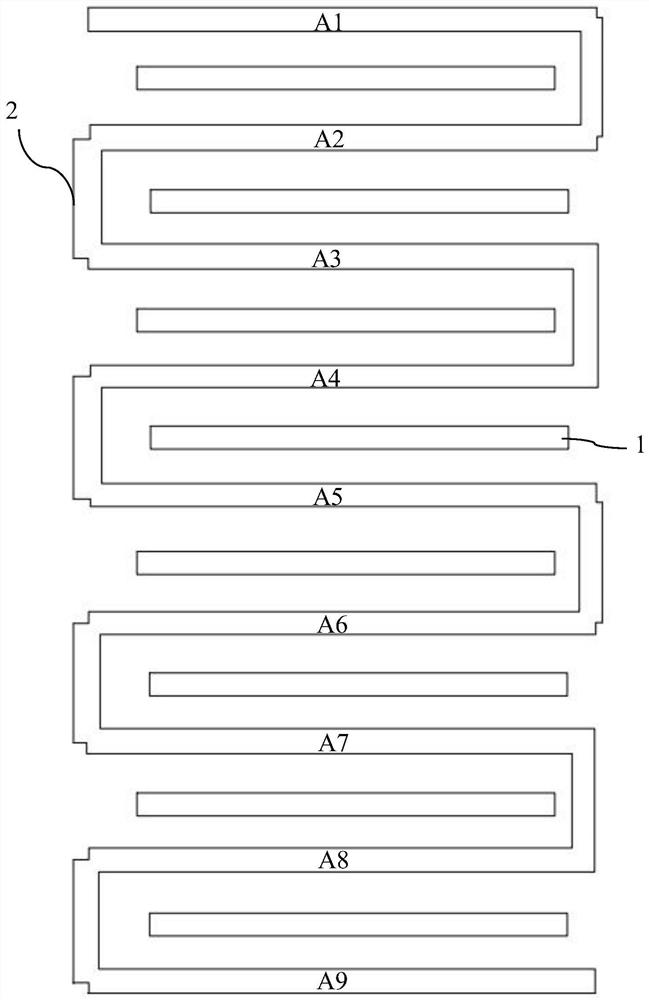

[0026] Reference attached Figure 1-2 , the present invention provides a folded insert type battery, comprising: an aluminum-plastic film outer package and an electrode group, wherein the electrode group is housed inside the aluminum-plastic film outer package, and the cavity formed by the electrode group and the aluminum-plastic film outer package It is filled with electrolyte solution; the pole group includes a first pole piece 1 and a composite electrode 2 , the composite electrode 2 is designed in a Z-shaped fold, and the folded composite electrodes 2 are interleaved with the first pole piece 1 .

[0027] The present invention also includes a pole lug, and the guide handle 3 of the pole group is connected to the pole lug by welding.

[0028] The tab includes a metal strip and tab glue, the tab glue is fused on the metal strip, and the metal strip is welded to the guide handle 3 .

[0029] The composite electrode 2 includes a second pole piece 4 and a diaphragm 5, and the ...

Embodiment 2

[0033] The present invention also provides a manufacturing process of a folded insert type battery. The composite electrode of the pole group is folded in a Z shape, and the first pole piece is inserted between the folded composite electrodes, and then the pole group is accommodated in an aluminum-plastic film In the outer packaging, the guide handle of the pole group and the metal strip of the tab are welded together, the tab glue and the aluminum-plastic film are welded together, and then the electrolyte is injected to form a folded insert battery.

[0034] The composite electrode includes a second pole piece and a diaphragm, and the second pole piece and the diaphragm are combined together.

[0035] In this embodiment, the second pole piece is a whole pole piece, which can be used as a negative pole or a positive pole, and is provided with a single guide handle or a plurality of guide handles, and the guide handle is molded by laser die-cutting or tool die-cutting , the gui...

Embodiment 3

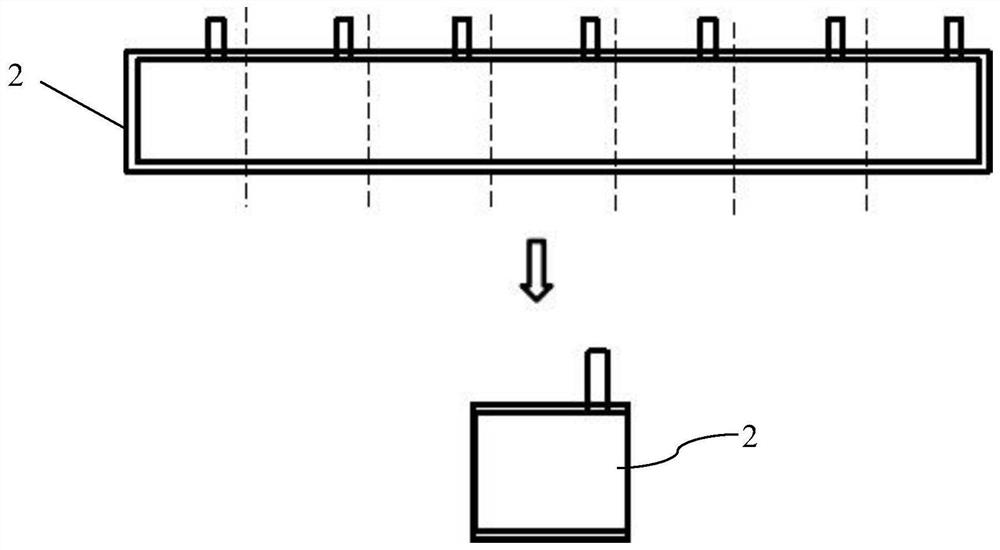

[0040] Such as image 3 As shown, the difference between this embodiment and embodiment 1 is that the composite electrode is formed in the following manner: the second pole piece is composited with the diaphragm, then cut and stacked.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com