Lithium ion battery structure and tab electric connection method

A lithium-ion battery and negative electrode connection technology, which is applied to small-sized batteries/battery packs, structural parts, secondary batteries, etc., can solve the problems of the connection mode of the positive terminal with many lines, the safety needs to be improved, and it is not conducive to mass production. , to achieve the effect of reducing the die-cutting pole piece process of the battery cell, reducing the occupation of the internal space of the battery cell, and increasing the utilization rate of the module space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a lithium-ion battery structure;

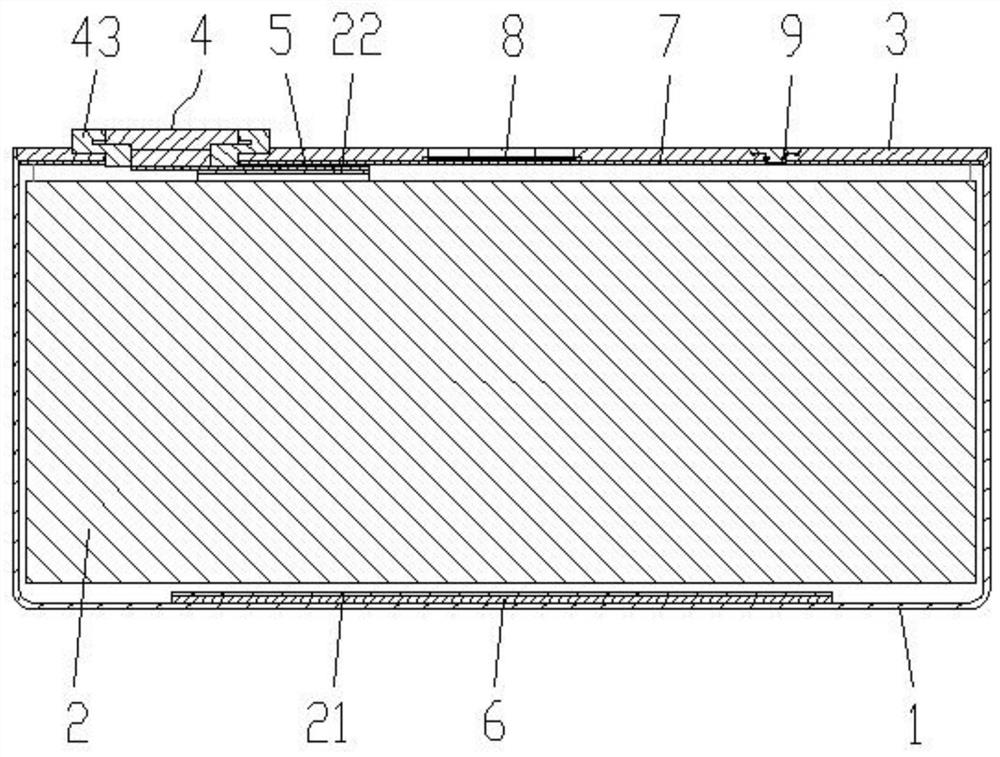

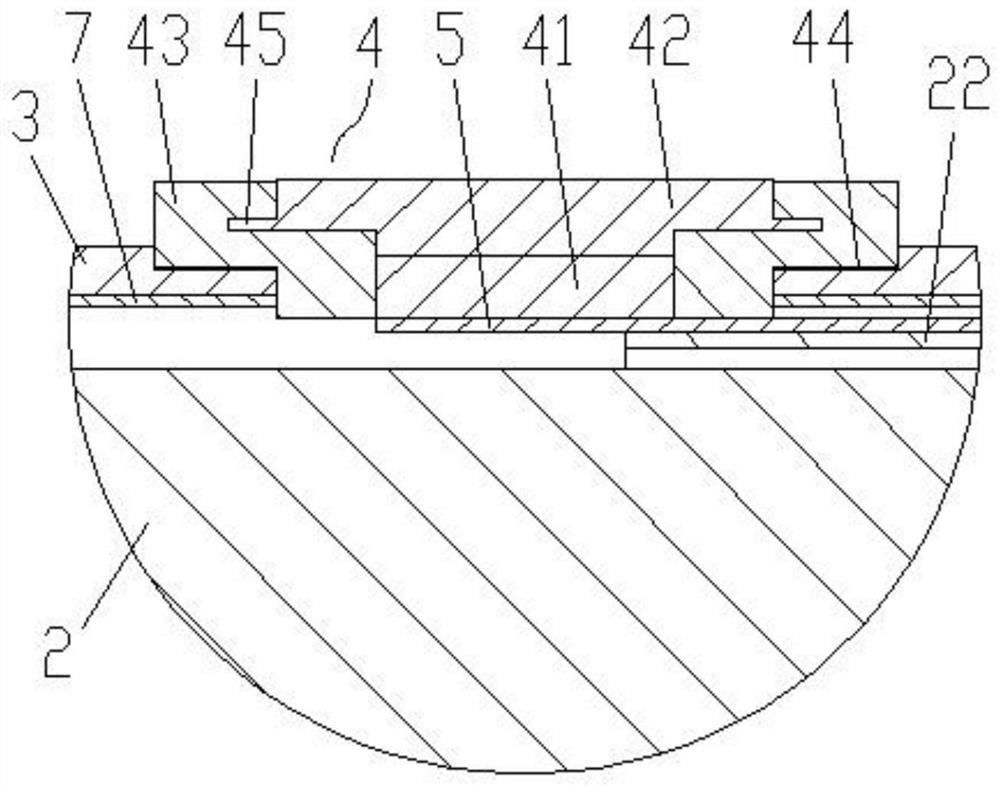

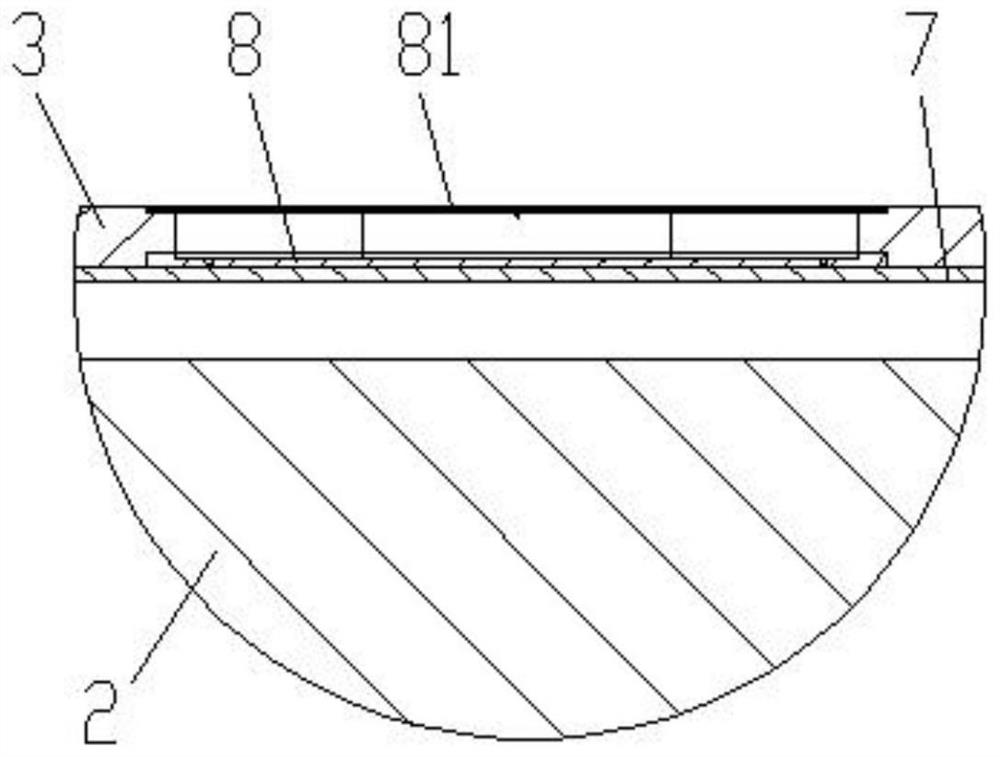

[0033] like Figure 1-Figure 8 As shown, the lithium-ion battery structure in this embodiment includes a casing 1, a battery cell 2 and a top cover 3, and there are several battery cells 2 arranged side by side inside the casing 1, and the top cover 3 is welded to On the top of the housing 1, the battery cell 2 is provided with positive tabs 21 and negative tabs 22, the positive tabs 21 are full tabs, and the positive tabs 21 and negative tabs 22 are respectively located on the upper and lower sides of the battery cell 2. side, wherein the negative tab 22 is located on the upper side of the cell 2, the positive tab 21 is located on the lower side of the cell 2, the top cover 3 is provided with a negative post 4, and the negative tab 22 is connected to the The negative pole 4 is connected to each other, and the positive tab 21 is connected to the bottom of the casing 1 through the positive connecting piece 6 . ...

Embodiment 2

[0044] This embodiment provides a method for electrically connecting the tabs of the lithium-ion battery structure as described in Example 1. Laser welding the negative tab of the battery cell to one side of the negative electrode connecting piece, and then welding the other side of the negative electrode connecting piece to the Negative pole laser welding; laser welding the positive ear of the cell to one side of the positive connecting piece, and then laser penetration welding the other side of the positive connecting piece to the bottom of the shell. This tab electrical connection method not only securely connects the negative tab of the cell to the negative column of the top cover, and tightly connects the positive tab to the bottom of the case, but also keeps the case intact after welding, preventing liquid leakage, bulging, etc. The ear die-cutting process reduces equipment wear and cost, and increases production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com