A kind of ventilation pipe for sweet potato cellar

A technology for ventilation pipes and sweet potatoes, applied in the field of sweet potato storage, can solve the problems of sweet potato eating, sweet potato rot and the like, and achieve the effect of reducing the problem of excessive noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

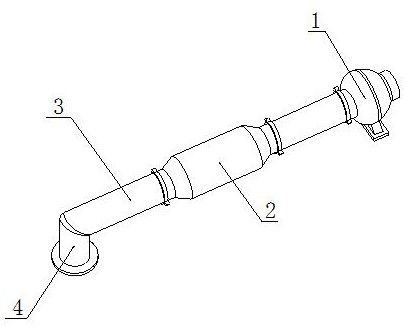

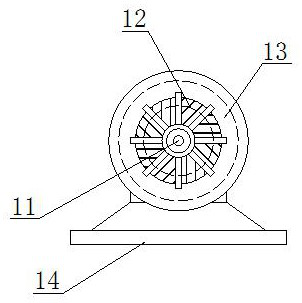

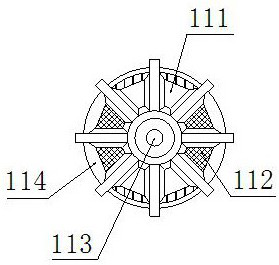

[0030] as attached figure 1 to the attached Figure 5 shown:

[0031] Its structure includes a blocking tube 1, a muffler tube 2, a connecting tube 3, and an air outlet 4. Both ends of the muffler tube 2 are respectively connected to the connecting tube 3 through flanges, and the end of the connecting tube 3 on one side is connected to the top of the air outlet 4. The end of the connecting pipe 3 on the other side is welded with the blocking cylinder 1. The blocking cylinder 1 includes a partition turntable 11, an air inlet and outlet 12, a circulation cylinder 13, and a fixed seat 14. The isolation turntable 11 is integrally connected with the circulation cylinder 13. The two ends of the circulation cylinder 13 are connected with the inner end of the air inlet and outlet 12, the interior of the air inlet and outlet 12 is in clearance fit with the surface of the partition turntable 11, and the outer wall of the circulation cylinder 13 is embedded and fixed with the upper end ...

Embodiment 2

[0038] as attached Image 6 to the attached Figure 9 shown:

[0039] The muffler cylinder 2 includes a muffler component 21 , an intercommunication cavity 22 and a stabilization ring 23 . The muffler composition 21 is integrally connected to the interior of the stabilization ring 23 , and the two walls of the stabilization ring 23 are engaged with the inner wall of the intercommunication cavity 22 . Connection, the interior of the intercommunication cavity 22 is integrally movably coordinated with the silencing component 21, the silencing component 21 is distributed in the intercommunication cavity 22, and the whole is embedded and connected with the center of the stabilizing ring 23, wherein the silencing component 21 is conducive to the intercommunication cavity 22. The hollow sound formed during the ventilation process is weakened, and the occurrence of noise or abnormal sound formed inside the intercommunication cavity 22 is reduced.

[0040] The noise reduction compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com