Fixed bent iron for installing tension type screen

An installation and screen technology, which is applied in the fields of filter screen, solid separation, chemical instruments and methods, etc., can solve the problems of increasing the installation workload and installation difficulty, affecting the strength of the screen machine, and troublesome installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

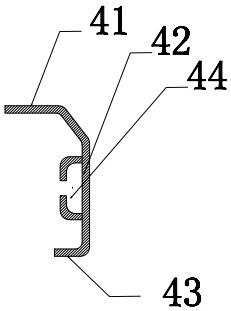

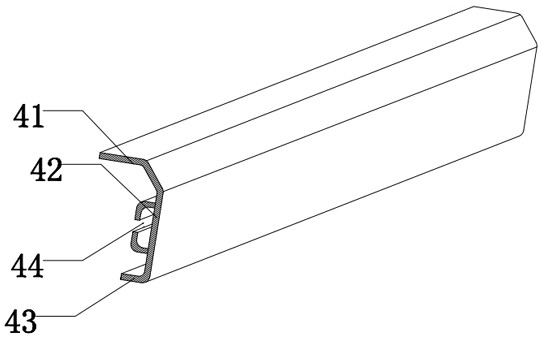

[0014] Such as figure 1 , figure 2 As shown, the fixed bent iron 4 is in a "giant" shape, including an upper support plate 41, a vertical plate 42, a lower hook plate 43 and a C-shaped groove 44. The upper support plate 41, vertical plate 42, and lower hook plate 43 are sequentially connected into a whole, the upper support plate 41 and the lower hook plate 43 are all bent to one side, and the inner side of the vertical plate 42 is provided with a C-shaped groove 44 .

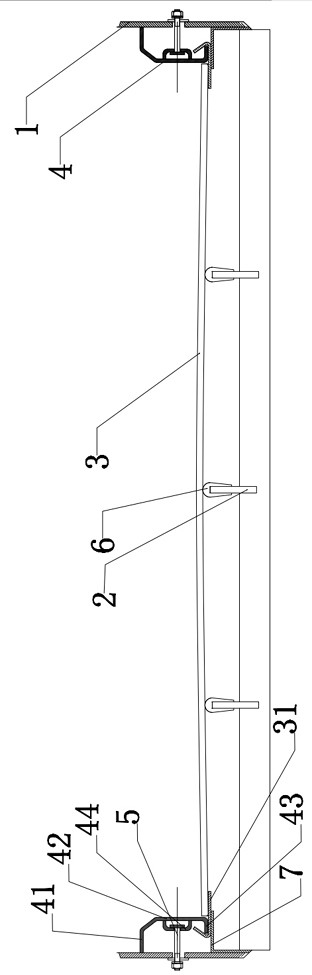

[0015] Such as image 3 As shown, the screen mesh supporting frame 2 is installed on the girder of the screen machine, the screen mesh 3 is flatly laid on the screen mesh supporting frame 2, and the two ends of the screen mesh 3 are provided with upward bending and tightening hooks 31. The bending tension hook 31 is covered on the angle iron 7, and the angle iron 7 is arranged on the inner wall plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com