Mold grinding and cleaning equipment

A technology for cleaning equipment and molds, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc., and can solve problems such as inability to fix molds, lack of cleaning functions, and poor grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

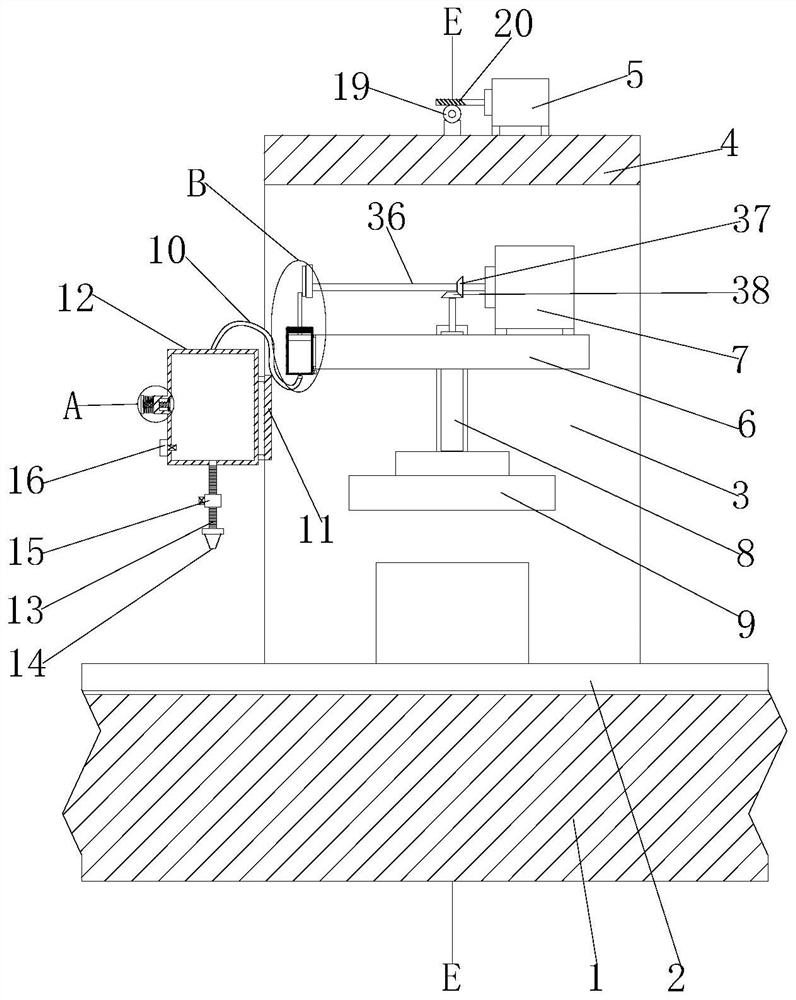

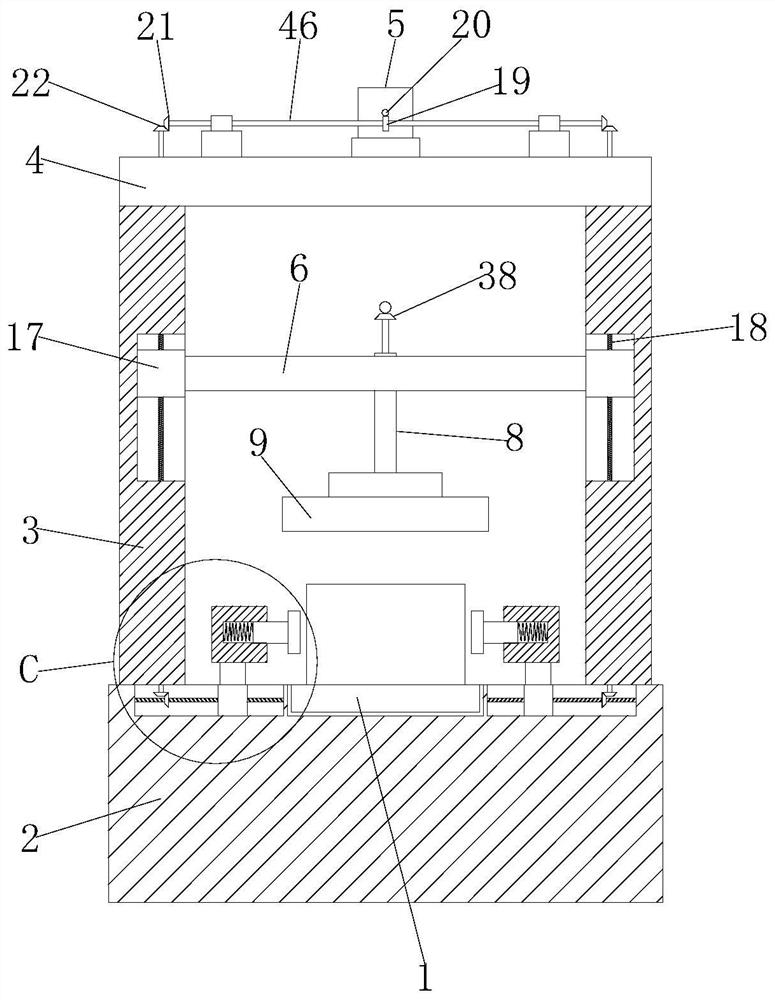

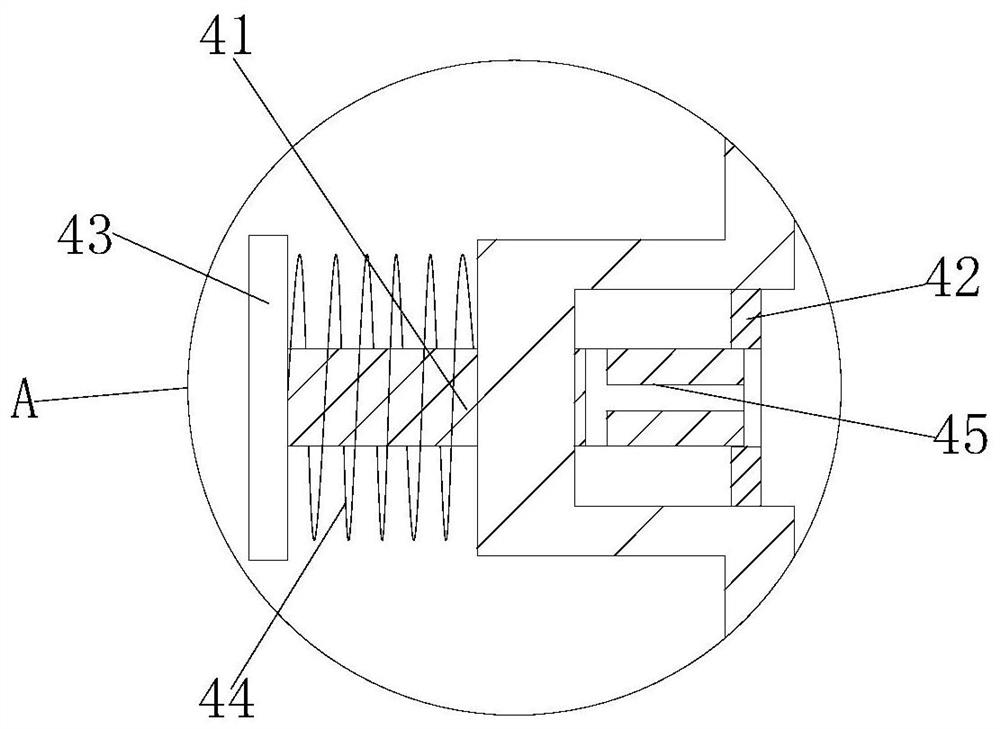

[0030] refer to Figure 1-6 , a mold grinding and cleaning equipment, including a base 1, the top of the base 1 is provided with a transmission plate 2, and the top of the base 1 is fixedly connected with two support plates 3 by welding, and the top ends of the two support plates 3 are fixedly connected by welding. The same top plate 4, the top of the top plate 4 is fixed with a first motor 5 by bolts, the side of the two supporting plates 3 close to each other is rotated and installed with the same lifting plate 6, and the top of the lifting plate 6 is fixed with a second motor 5 by bolts. The motor 7, the lifting plate 6 are provided with a rotating hole, and the rotating hole is equipped with a grinding shaft 8, and the bottom end of the grinding shaft 8 is fixedly connected with a grinding wheel 9 by welding, and the grinding shaft 8 is matched with the second motor 7, and the base 1 Two clamping mechanisms are arranged on the top of the top, and the two clamping mechanism...

Embodiment 2

[0042] The difference from Embodiment 1 is that the output shaft of the first motor 5 is connected with the seventh bevel gear, the outer fixed sleeve of the rotating rod 46 is provided with the eighth bevel gear, and the eighth bevel gear meshes with the seventh bevel gear .

[0043] In the present invention, when in use, the mold that needs to be polished is placed on the transmission plate 2, and the transmission plate 2 drives the mold to be displaced to directly below the grinding wheel 9 and then stops. At this time, the output shaft of the first motor 5 drives the seventh bevel gear Rotate, the seventh bevel gear drives the eighth bevel gear to rotate, the eighth bevel gear drives the rotating rod 46 to rotate, the rotating rod 46 drives the first bevel gear 21 to rotate, the first bevel gear 21 drives the second bevel gear 22 to rotate, the second bevel gear The gear 22 drives the first screw rod 18 to rotate, the first screw rod 18 drives the first slider 17 to move d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com