Continuous fiber mixed-length chopping device

A continuous fiber, long and short technology, applied in the field of composite material chopping equipment, can solve the problems of low fiber chopping efficiency, time-consuming and labor-consuming, and low chopping quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

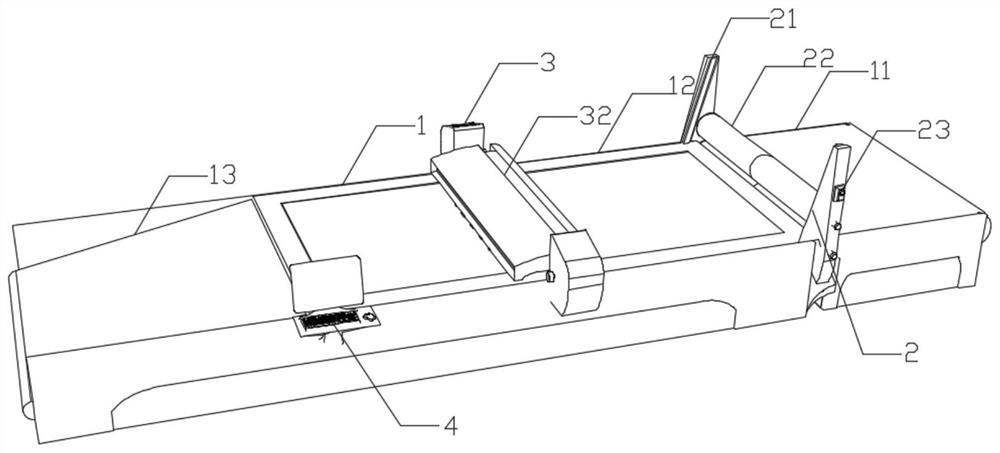

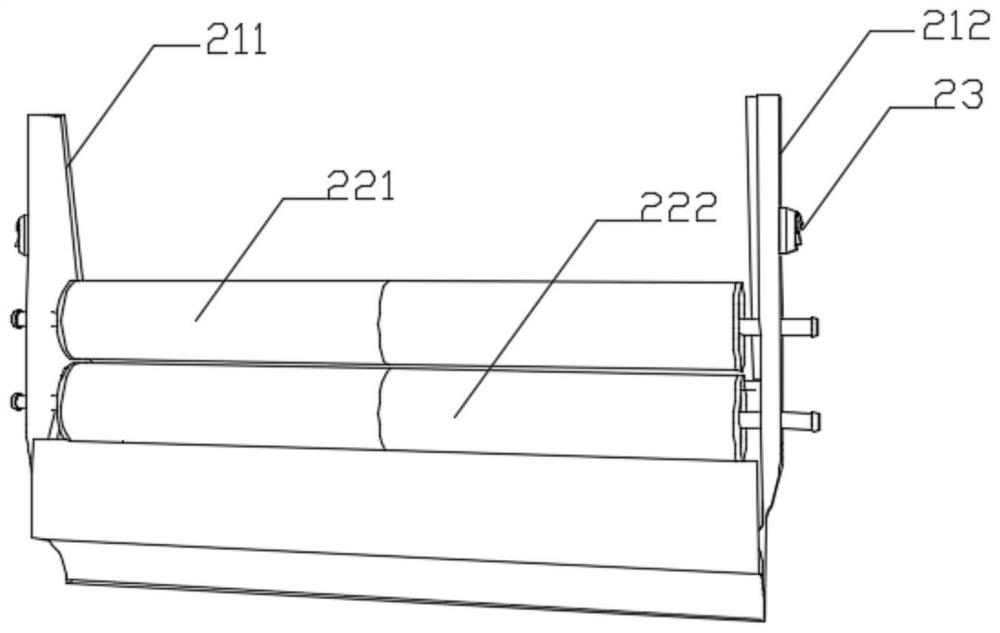

[0021] Such as figure 1 As shown, the continuous fiber mixed-length chopping device of the present invention includes a transmission mechanism 1, a pressing mechanism 2 and a cutting mechanism 3;

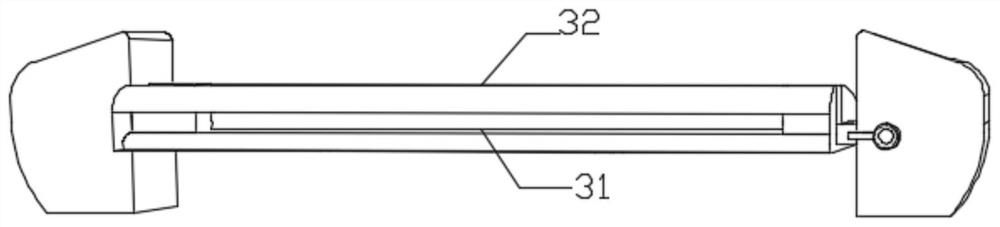

[0022] The conveying mechanism 1 includes a first conveying belt 11, a second conveying belt 12, and a feeding plate 13 arranged in sequence along the fiber advancing direction, and a pressing mechanism 2 is arranged between the first conveying belt 11 and the second conveying belt 12, and the conveying belt The front end of the material sheet 13 is close to the rear end of the second conveyor belt 12, and the cutting mechanism 3 is arranged on the second conveyor belt 12; the cutting time sequence of the cutting mechanism 3 can be adjusted according to the fiber length gradation.

[0023] As an improvement,

[0024] Also comprise numerical control mechanism 4, the signal output end of described numerical control mechanism 4 is connected with the first conveyor belt 11, the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com