Supporting operation platform for high-rise steel structure construction and mounting method of supporting operation platform

A technology for steel structure construction and operation platform, which is applied in the direction of house structure support, house structure support, building structure, etc., can solve the problems of reduced construction efficiency, inability to expand the scope of work, fixed scope of work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

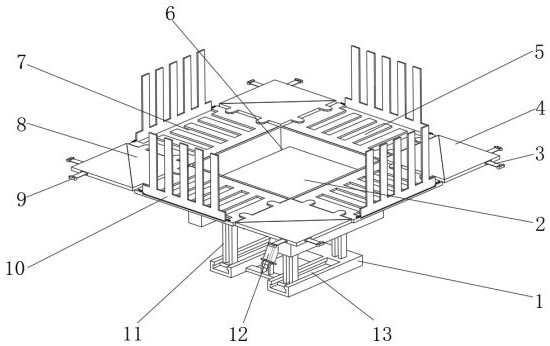

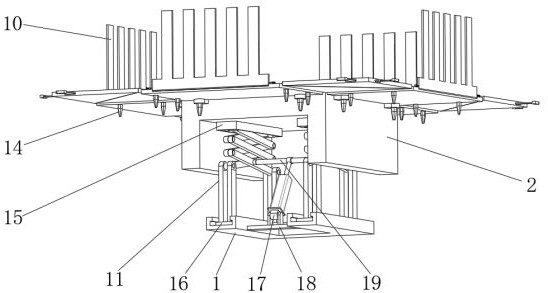

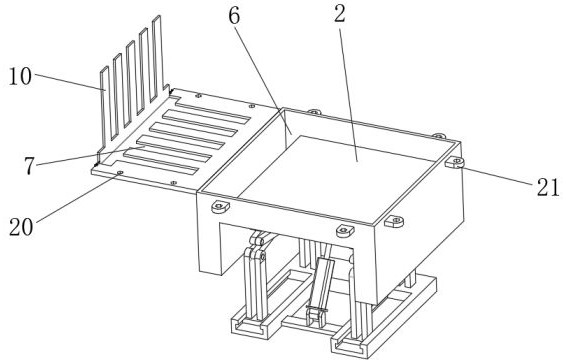

[0043] A supporting work platform for high-rise steel structure construction, such as Figure 1-4As shown, it includes a base 1, a support platform 2 and two scissor lift frames 11, the support platform 2 is installed on the top of the scissor lift frame 11, and the same support frame is welded between the inner walls on both sides of the base 1 18. The first hydraulic cylinder 12 is installed on the top of the support frame 18 through the hinge seat 17. The outer wall of the top side of the base 1 is provided with a lifting frame chute 13, and the outer wall of the bottom of the support platform 2 is provided with two installation rails 15; The two ends on one side of each scissor lift frame 11 are respectively fixed to the top outer wall of the base 1 and the bottom outer wall of the support table 2 by bolts, and the two ends on the other side of each scissor lift frame 11 are slidably connected to each other by a slider 16. In the lifting frame chute 13 and the mounting rai...

Embodiment 2

[0050] A supporting work platform for high-rise steel structure construction, such as Figure 5 , Image 6 As shown, in order to facilitate the adjustment of the position of the support platform 2; the present embodiment makes the following improvements on the basis of embodiment 1: the outer wall of the bottom of the base 1 is equipped with a roller 26, the bottom of the base 1 is provided with a slide rail 29, and the roller 26 rolls on the In the slide rail 29, a mounting plate is welded on the outer wall of one side of the slide rail 29, and the outer wall of one side of the mounting plate is fixed with a second hydraulic cylinder 27 by screws, and the output end of the second hydraulic cylinder 27 is fixed on one side of the support frame 18 by screws The outer wall: by setting the rollers 26, the second hydraulic cylinder 27 and the slide rail 29, etc., the position of the support table 2 can be adjusted conveniently, which improves the practicality.

[0051] For the co...

Embodiment 3

[0054] A method for installing a supporting work platform for high-rise steel structure construction, such as Figure 1-6 shown, including the following steps:

[0055] S1: The user lays the slide rail 29 on the construction site, judges according to the level bubble 28, and adjusts the threaded rod 31 to make the slide rail 29 level;

[0056] S2: Control the second hydraulic cylinder 27 to work, and push the scissor lift frame 11 to a designated position;

[0057] S3: the user takes out the edge mounting plate 5 and the corner flap 4 from the receiving cavity 6;

[0058] S4: install the edge mounting plate 5 in the mounting ear 21 on the outside of the support table 2 through the mounting column 14;

[0059] S5: Install the corner flap 4 in the assembly hole 20 of the edge mounting plate 5 through the assembly column 14;

[0060] S6: erect the guardrail 10, and fix the guardrail 10 through the fixing pin 22;

[0061] S7: Stand up the corner folded plate 4, pull the hangin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com