A tunnel construction trolley

A technology for tunnel construction and trolley, which is applied in drilling equipment, drilling equipment and methods, mining equipment, etc., can solve the problems of small number of arms of bolt support equipment, poor geology, and high labor intensity of workers, and achieves the improvement of anchorage. The effect of pole construction work efficiency, reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

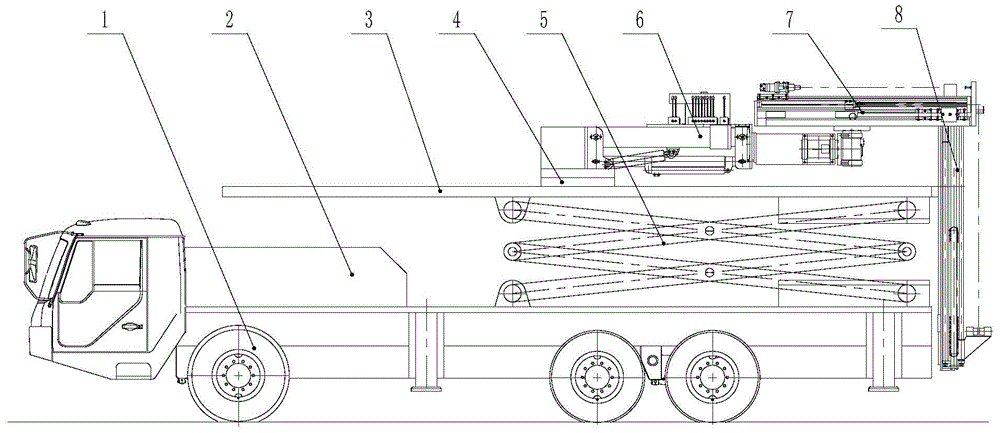

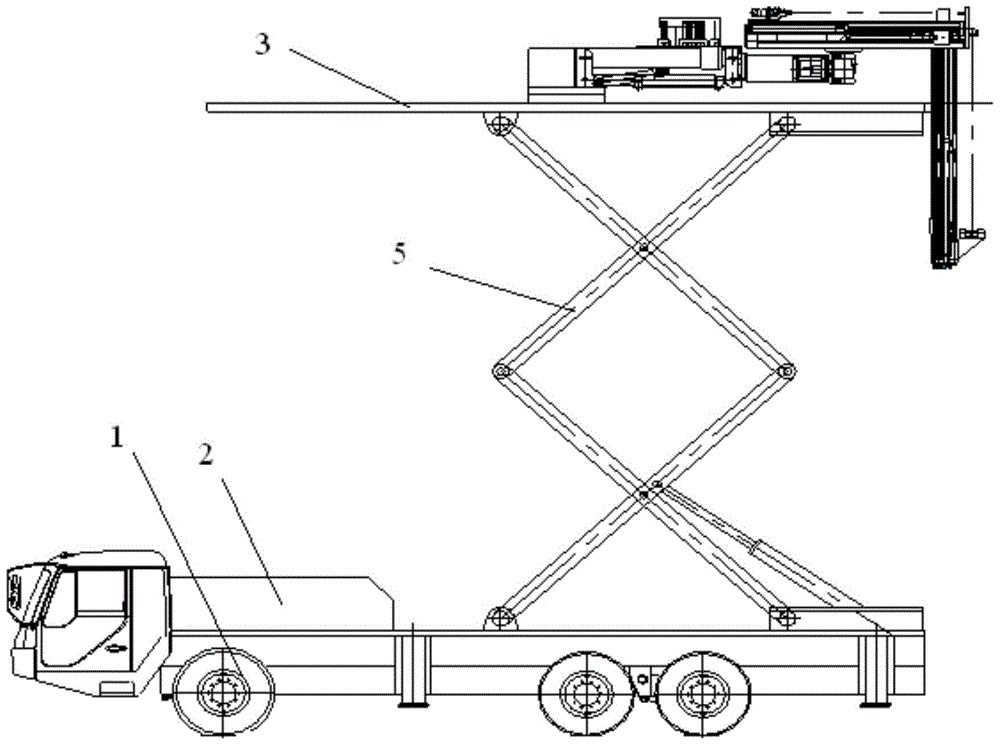

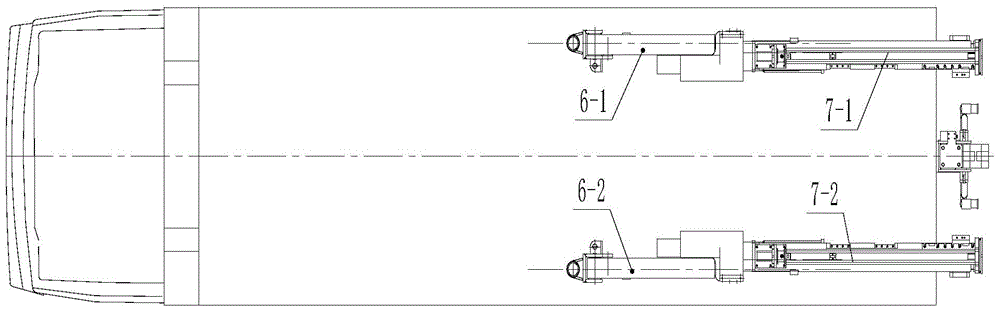

[0035] The invention is a tunnel construction trolley, which has a large lifting working platform, and is a multifunctional vehicle capable of carrying out full-section tunnel bolt support and lifting heavy objects. With various functions, it is suitable for various cross-section tunnels (especially large cross-section tunnels) and conforms to the domestic tunnel support construction technology and working conditions. The invention realizes the mechanization and automation of all-round construction of bolts in large-section tunnels, reduces the labor intensity of workers, improves the quality, accuracy and efficiency of bolt support construction, and better guarantees the quality of the project. It fundamentally solves the difficult problem of tunnel bolt support construction caused by the change of tunnel construction technology, insufficient mechanization of bolt support, and the variability of geological conditions.

[0036] Refer to attached figure 1 As shown, the tunnel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com