Rotating head spindle of high-speed steel wire braiding machine

A technology of rotary head and braiding machine, which is applied in the direction of braided fabrics, textiles and papermaking, etc. It can solve the problems of unsteady and stable pay-off of frame spindles, inconvenient disassembly and replacement, and no direction positioning, etc., so as to improve production efficiency and product quality. ,Easy pay-off and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

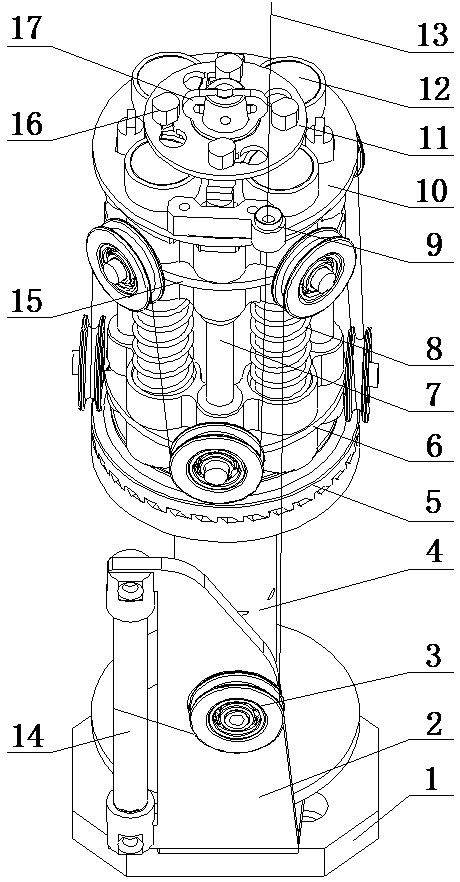

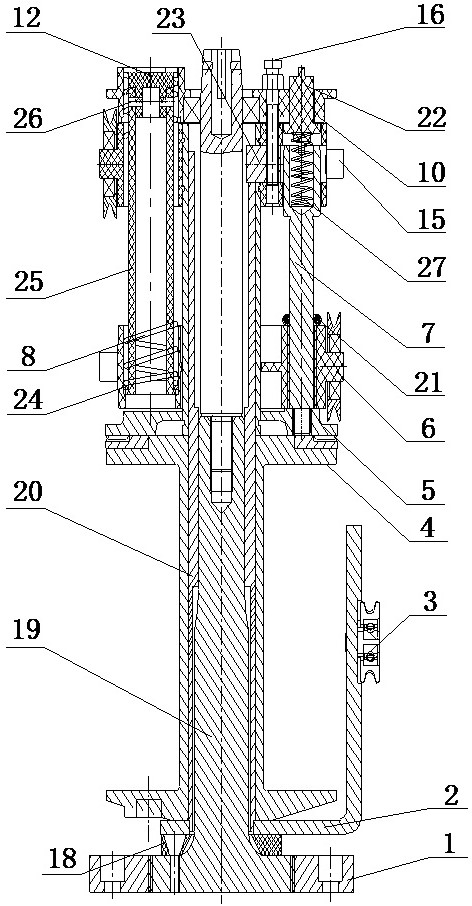

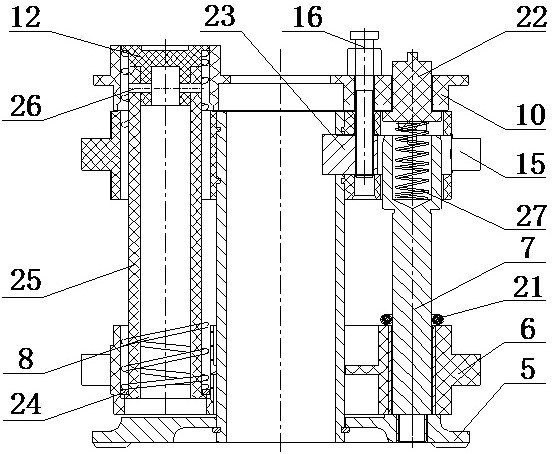

[0029] Embodiment: the rotary head spindle includes: base 1, bobbin 4, pressure cap 17, bobbin shaft spacer 18, bobbin shaft 19, center tube 20 of thread passing frame, guide wheel group, rotary head threading device and thread passing frame components;

[0030] Tighten the bobbin shaft 19 at the center of the base 1, the bobbin shaft spacer 18 is sleeved on the bobbin shaft 19, and fixed on the top of the base 1 with screws, and the bobbin shaft 19 is sleeved with the central tube of the wire stand 20: The bobbin shaft 19 above the bobbin shaft spacer 18 is connected with a bobbin assembly; the bobbin 4 is sleeved on the bobbin shaft 19, which is located at the position where the bobbin shaft 19 is connected with the bobbin assembly The lower end of the rotary head pay-off device is installed on the upper end of the bobbin 4, and the upper end of the rotary head pay-off device is stuck on the card slot of the center tube 20 of the wire frame through the T-shaped pin 23, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com