Engineering geological drilling and exploring equipment

A drilling equipment and engineering geology technology, applied in drilling equipment, drilling tools, earthwork drilling, etc., can solve problems such as deformation, bit damage, and increased friction between the bit and the soil layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

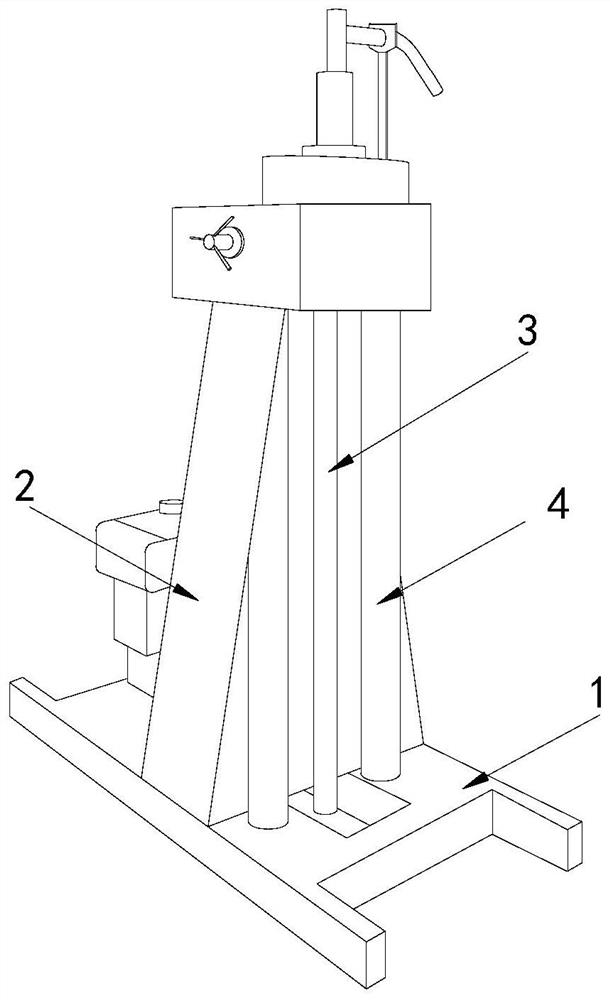

[0028] Example 1: Please refer to Figure 1-Figure 6 , the specific embodiments of the present invention are as follows:

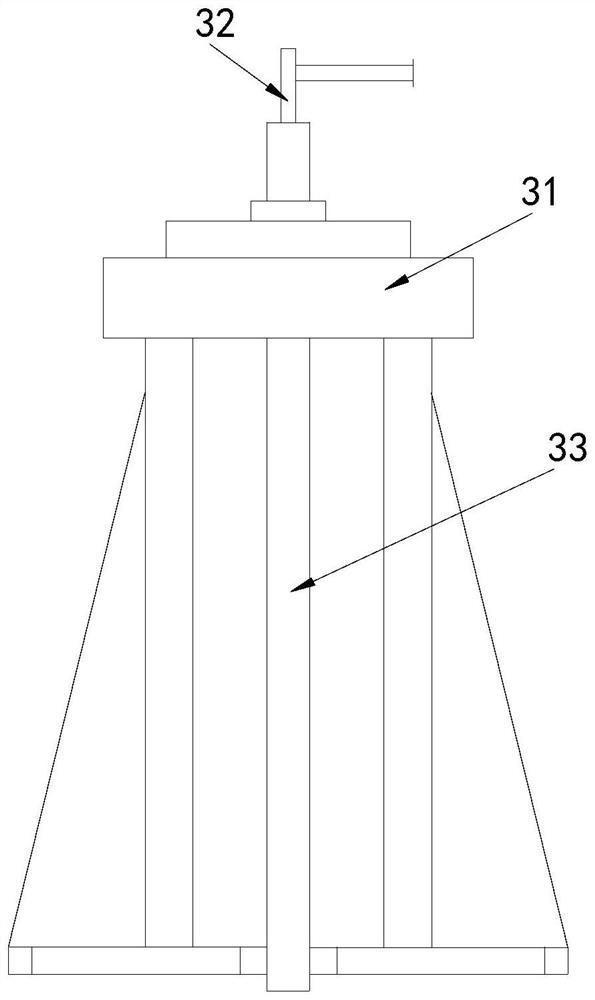

[0029] Its structure comprises support plate 1, support frame 2, main body 3, support column 4, and the top of described support plate 1 is provided with support frame 2, and described main body 3 is installed on the top front end of support frame 2, and described support column 4 is provided with There are two, and they are installed on both sides of the main body 3 respectively. The main body 3 includes a limiting platform 31, a water inlet pipe 32, and drilling equipment 33. The limiting platform 31 is installed on the top of the support frame 2. The inlet The water pipe 32 is installed vertically on the top of the limiting platform 31 , and the drilling equipment 33 passes through the limiting platform 31 and is connected with the water inlet pipe 32 .

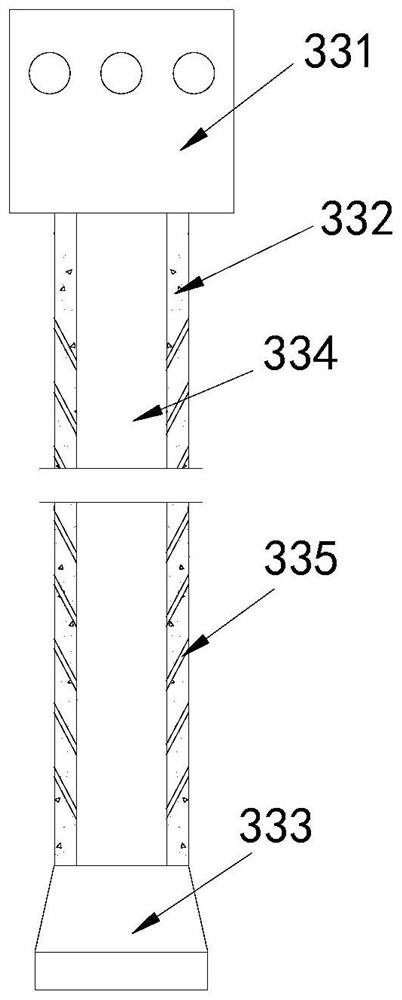

[0030] The drilling equipment 33 includes a mounting seat 331, a drilling pipe 332, a drilling blo...

Embodiment 2

[0035] Example 2: Please refer to Figure 7-Figure 9 , the specific embodiments of the present invention are as follows:

[0036]The friction device a4 includes a friction block c1, a cut groove c2, a water outlet c3, and a friction groove c4. There are eight friction blocks c1 arranged around the bottom end surface of the drill bit a1. The cut groove c2 is set There are eight of them, and they are located between two friction blocks c1. The water outlet c3 is set in the cut groove c2. The friction groove c4 is located on the front and rear end surfaces of the friction block c1. The friction groove c4 is wave-shaped, which is beneficial to The friction force with the soil is improved through the friction groove c4.

[0037] The water outlet hole c3 includes a water storage tank c31, a fine flow hole c32, a water outlet port c33, and a soil retaining block c34. The water storage tank c31 is arranged at the upper end of the cutting groove c2. Arranged on the top end surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com