Mounting device for field unit

A field device, fastening device technology, applied in the direction of measurement device, antenna support/installation device, utilization of re-radiation, etc., can solve the problem of unspecified antenna connection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

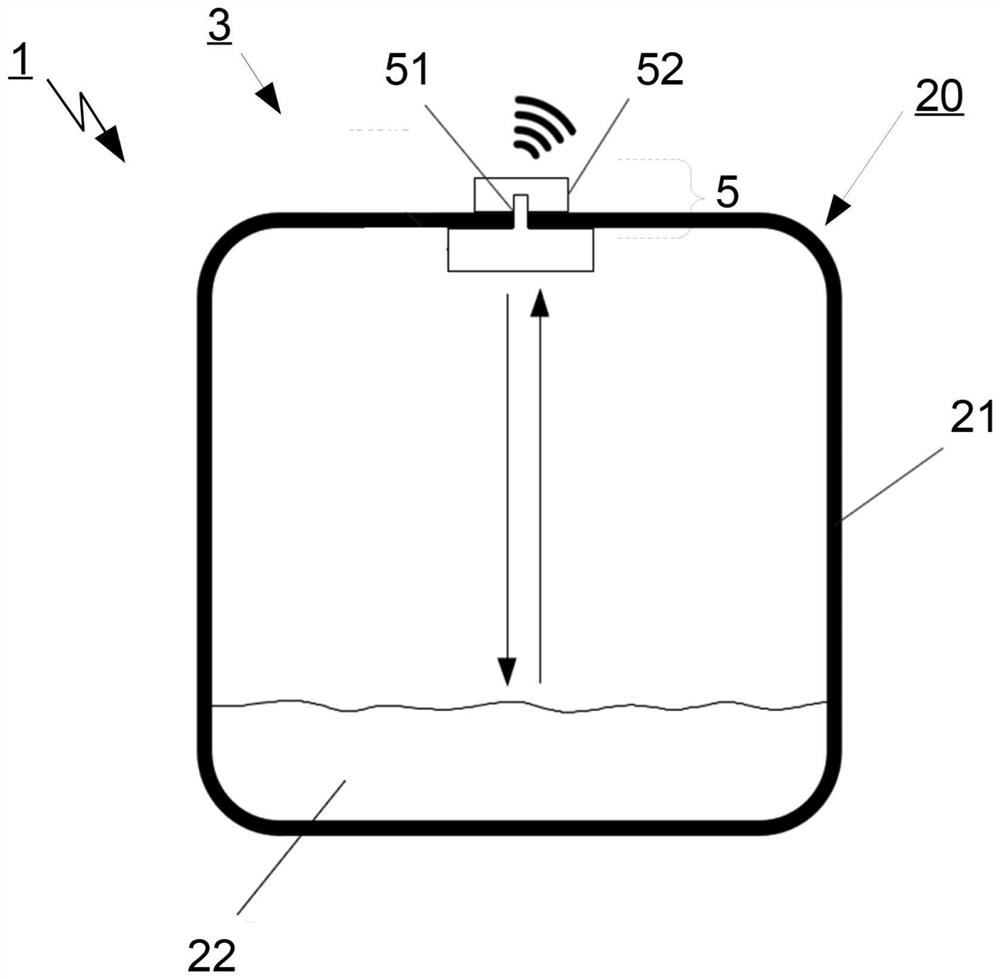

[0049] figure 1 Shown is a metering device 1 according to the present application for filling level measurement in a metal tank with an autonomous field device 3 formed as a filling level metering device.

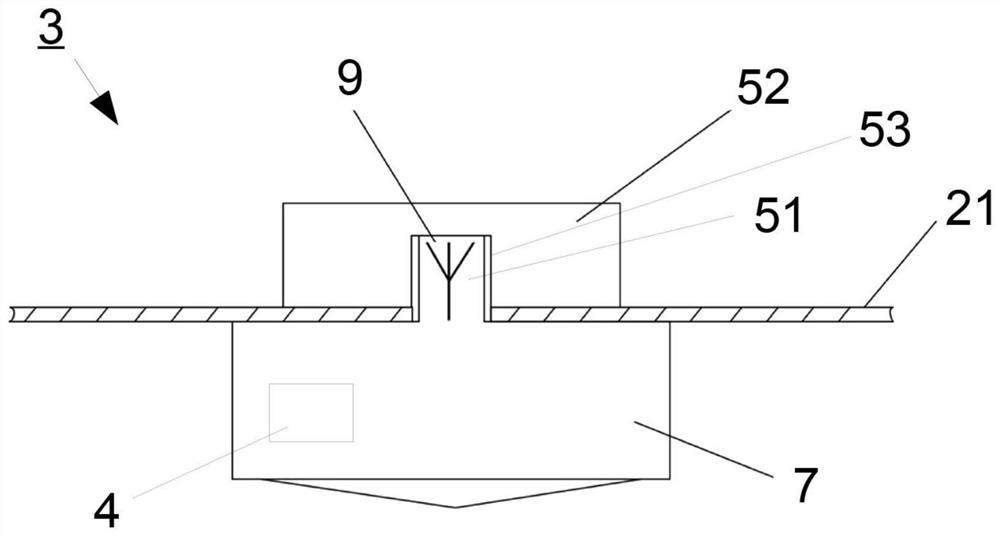

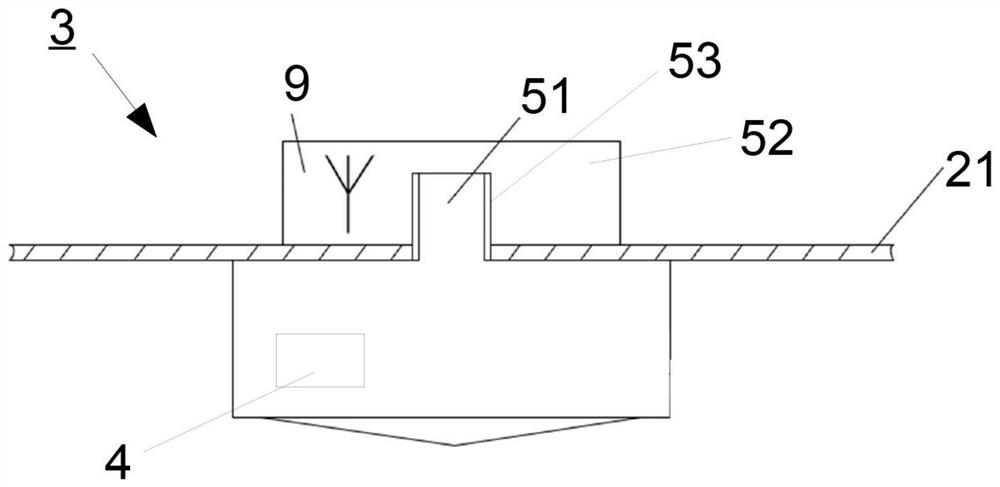

[0050] In the present embodiment, the autonomous level metering device 3 is formed as a radar level metering device and measures the level of the medium 22 in the container 20 . In the wall 21 of the container 20 is formed a hole in which the autonomous level metering device 3 is held using fastening means 5 . To this end, the fastening device 5 has a first sensor-side part 51 which is arranged in the container 20 together with at least a radar sensor for fill level measurement.

[0051] The fill level sensor is arranged in a cylindrical housing 7 which is integrally formed with the first part 51 of the fastening device 5 . In order to form the mechanical interface, the first part 51 of the fastening means has a cylindrical bolt-like extension which is arranged in the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com