Steel pipe with integrated connecting structure

A connection structure and one-piece technology, applied in the direction of connection components, rod connections, non-detachable pipe connections, etc., can solve the problems of easy water seepage, cumbersome joints, and easy cracking at the joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

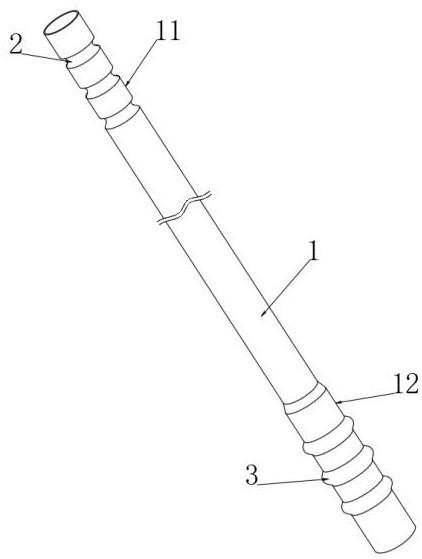

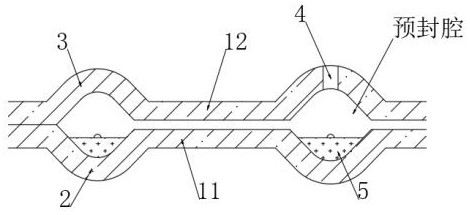

[0043] see figure 1 , a steel pipe with an integrated connection structure, comprising a pipe body 1, one end of the pipe body 1 is fixedly connected with an inner sealing end 11, the other end of the pipe body 1 is fixedly connected with an outer sealing end 12, and the inner sealing end 11 and the outer sealing end The ends 12 are matched with each other, the inner sealing end 11 is provided with a plurality of evenly distributed inner convex rings 2, and the outer sealing end 12 is provided with a plurality of evenly distributed outer convex rings 3, and the inner convex ring 2 and the outer convex ring 3 are connected to each other. match.

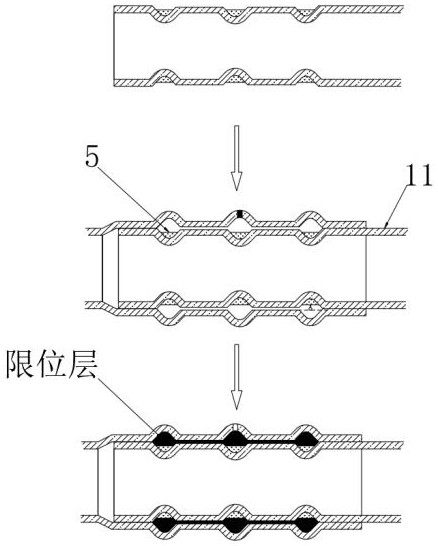

[0044] see Figure 3-4 , the upper end of the outer convex ring 3 located in the middle is dug with a material injection port 4, and the outer end of the inner convex ring 2 is provided with a pair of silicone half-rings 5 with magnetic sheets 6 at the ends. The inner wall of the sealing end 12 and the outer surface of the inner se...

Embodiment 2

[0054] In this embodiment, there is no silicone half-ring 5 outside the inner convex ring 2 and its related technical features. After the two steel pipes are plugged into each other, they are directly fixed and sealed by pouring molten plastic, and the rest are consistent with Embodiment 1.

[0055] This embodiment is suitable for transporting liquids with relatively stable hydraulic pressure, or liquids that are transported smoothly. In this case, the strength requirement for the limiting layer is relatively low, and this arrangement makes the cost lower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com