Non-contact pipeline flowing ore pulp concentration online device and detection method

A pulp concentration, non-contact technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of frequent maintenance of weighing cleaning equipment, low sampling accuracy, large concentration error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

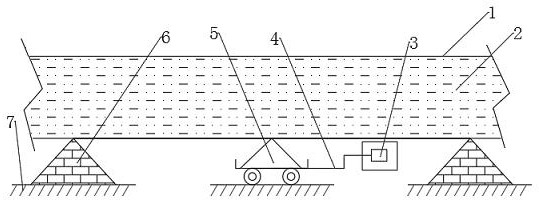

[0044] A non-contact method for on-line detecting the concentration of pipeline flowing pulp, comprising the following steps:

[0045] ⑴Initial data testing and input:

[0046] When the tube is empty, the weight taken by the floor scale electronic scale 5 is M 0 =50Kg; when the pipeline is filled with flowing water, the weight taken by the floor scale electronic scale 5 is M 1 =150Kg; the true specific gravity of the fixed material in the pulp is determined to be p=3, and the obtained M 1 , M 0 , p initial data input to the concentration data processing display 3.

[0047] ⑵On-line test of pulp concentration in the pipeline:

[0048] Set the initial error coefficient r=1, the real-time weight M of the pipeline 1 weighed by the floor scale electronic scale 5, the unit is Kg; it is transmitted to the concentration data processing display 3 through the data transmission line 4, and is calculated and output through the online output mass concentration data model The pulp mass...

Embodiment 2

[0063] A non-contact method for on-line detecting the concentration of pipeline flowing pulp, comprising the following steps:

[0064] ⑴Initial data testing and input:

[0065] When the tube is empty, the weight taken by the floor scale electronic scale 5 is M 0 =150Kg; when the pipeline is filled with flowing water, the weight taken by the floor scale electronic scale 5 is M 1 =310Kg; the true specific gravity of the fixed material in the pulp is determined to be p=2.5, and the obtained M 1 , M 0 , p initial data input to the concentration data processing display 3.

[0066] ⑵On-line test of pulp concentration in the pipeline:

[0067] Set the initial error coefficient r=1, the real-time weight M of the pipeline 1 weighed by the floor scale electronic scale 5, the unit is Kg; it is transmitted to the concentration data processing display 3 through the data transmission line 4, and is calculated and output through the online output mass concentration data model The pulp m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com