Ultrasonic thermal excitation stroke adaptive loading device and method for concrete mesoscopic defects

A loading device and concrete technology, which is applied in the field of hidden defect detection in concrete engineering, can solve the problems of strict process control requirements, complicated coupling pressure application device, difficulty in adapting to large-scale detection requirements, etc., to achieve efficient recovery, convenient layout, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

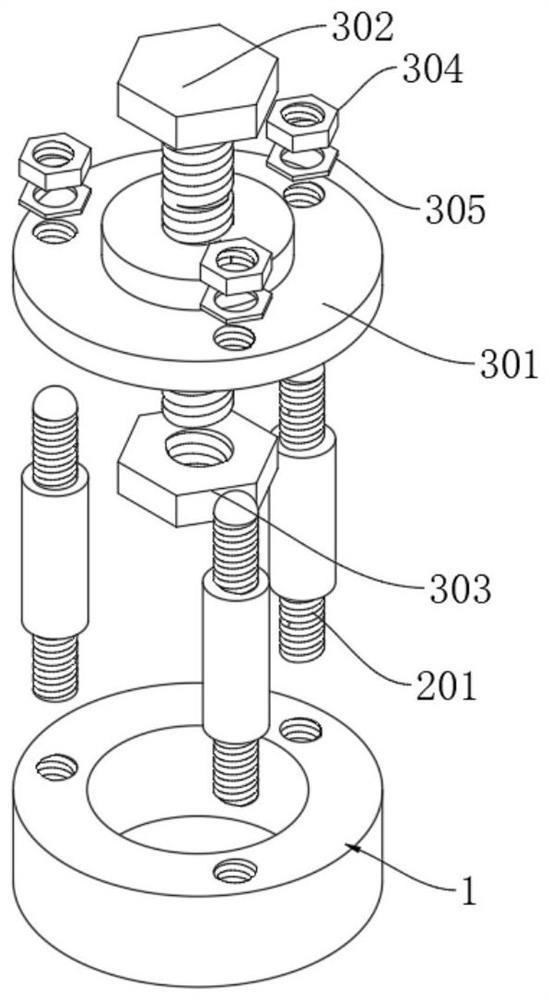

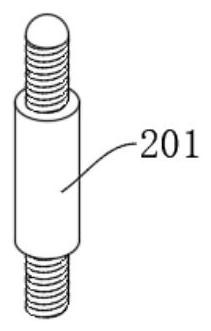

[0030] An ultrasonic thermal excitation stroke adaptive loading device for concrete mesoscopic defects, including: a rigid fixing unit 1, a semi-flexible supporting unit 2 and a rigid loading unit 3, and the rigid fixing unit 1 and the excited object are bonded and connected by a cured adhesive , the upper side of the rigid fixing unit 1 is threadedly connected to the lower end of the semi-flexible supporting unit 2, the upper end of the semi-flexible supporting unit 2 is threadedly connected to the lower side of the loading unit 3, and the rigid fixing unit 1, the semi-flexible supporting unit 2 and the rigid loading unit 3 are from bottom to top Connected in sequence to form a rigid system consisting of adhesive, rigid fixing unit 1 and rigid loading unit 3, matching the coupling pressure of semi-flexible support unit 2, the ultrasonic thermal excitation stroke adaptive loading device is stably applied, and the excitation stroke adaptive loading device functions The object is...

Embodiment 2

[0042] Example 2: Based on Example 1, but with the following differences:

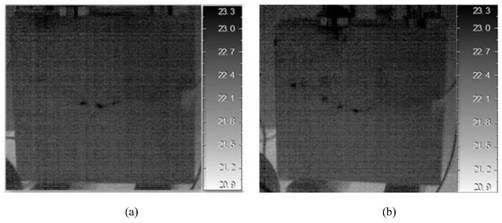

[0043] refer to image 3 , using the method in Example 1, the middle of the 430mm×400mm×100mm concrete block was wedged and split to produce transverse cracks, but the cracks did not completely penetrate the test block in the transverse direction, and the crack opening width was 0.01~0.38mm . Use the pressure clamp and the excitation stroke adaptive loading device in turn to apply 1500N coupling pressure to the 40kHz ultrasonic transducer with a rated power of 50W, connect the ultrasonic circuit to excite the concrete sample for 10s, and capture the thermal image, such as image 3 .

[0044] from image 3 It can be seen from the two loading methods that the cracks in the thermal images are excited with a visible temperature rise: image 3 In (a), the difference between the temperature rise at the identifiable crack and the temperature rise of the surrounding concrete is mainly concentrated in 0.3~0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com