Construction of stamen-type s-doped manganese-copper electrocatalysts based on metal polyphenol-modified sodium alginate/nanocellulose composite aerogels

A composite aerogel and nanocellulose technology, applied in circuits, structural parts, electrical components, etc., can solve problems such as the single synthesis cost of precursors, and achieve the effects of excellent limiting current, simple equipment, and strong resistance to methanol poisoning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

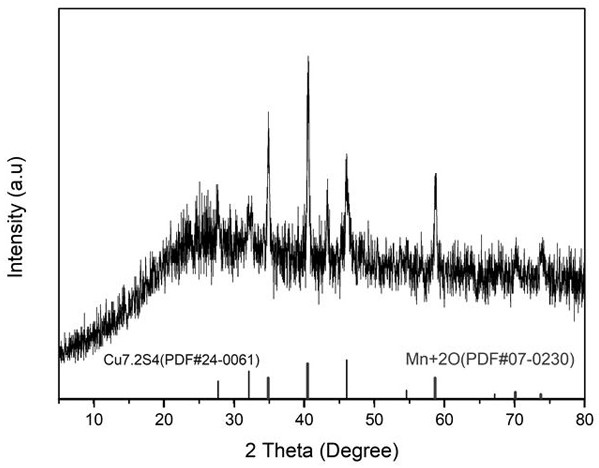

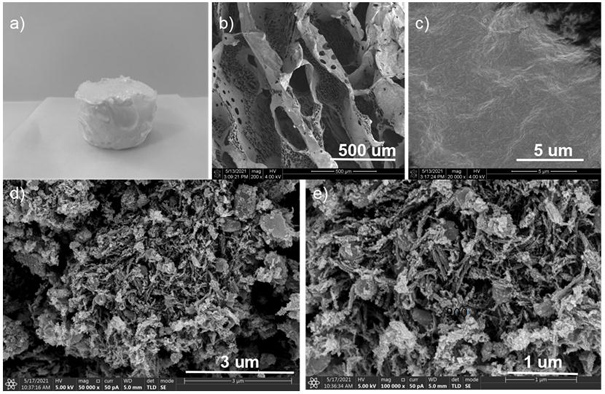

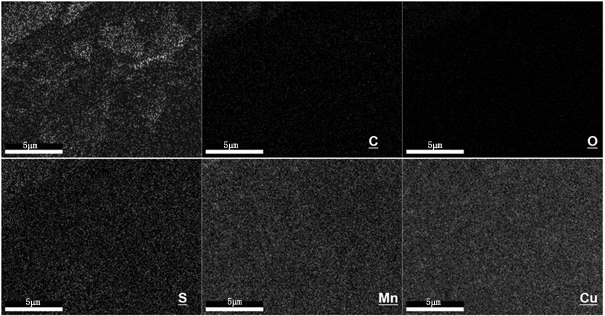

[0051] The present embodiment demonstrates a C@MnOCu 7.2 S 4 -Synthesis method of TA catalyst:

[0052] (1) Weigh 3g of cotton in a three-neck round bottom flask, add 13mL of concentrated sulfuric acid (98%) and 13mL of deionized water, stir at a uniform speed of 1.5h in a 45 °C water bath pot, and then dilute the sulfuric acid with deionized water to terminate the hydrolysis reaction, and remove the supernatant after standing. The lower suspension is then centrifuged in a high-speed centrifuge (10000 rpm / min, 10min / time) until the milky white liquid appears, and the milky liquid is collected sequentially to obtain a nanofibrous crystal (CNC) solution.

[0053] (2) Take 2g of sodium alginate and dissolve it in 100mL deionized water, and carry out magnetic stirring at room temperature for 2h.

[0054](3) Take 100mL nanofiber crystal solution and 100mL sodium alginate solution mixed at room temperature for magnetic stirring for 2h, then pour into a plastic mold, and then freeze-dry ...

Embodiment 2

[0064] The present embodiment demonstrates a C@MnOCu 7.2 S 4 -Study on the electrochemical properties of TA nanocomposite catalysts.

[0065] The catalyst preparation process of the present invention added Nafion is produced by Aldrich Sigma Company, the concentration of 5wt%.

[0066] The catalyst is pipetted with a pipette 7 ul droplets onto the working electrode, waiting for natural drying and then repeating this step 3 times, followed by slowly entering the working electrode into the oxygen saturated 0.1 M KOH electrolyte, in this step to prevent the formation of bubbles on the working electrode, the electrolyte should continue to pass through oxygen during the entire test to ensure oxygen saturation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com