Sealing assembly and battery negative pressure formation and secondary liquid supplementing method

A technology for sealing components and batteries, which is applied to battery components, circuits, electrical components, etc., and can solve problems such as polluting the environment, small size of sealing nails, and affecting battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

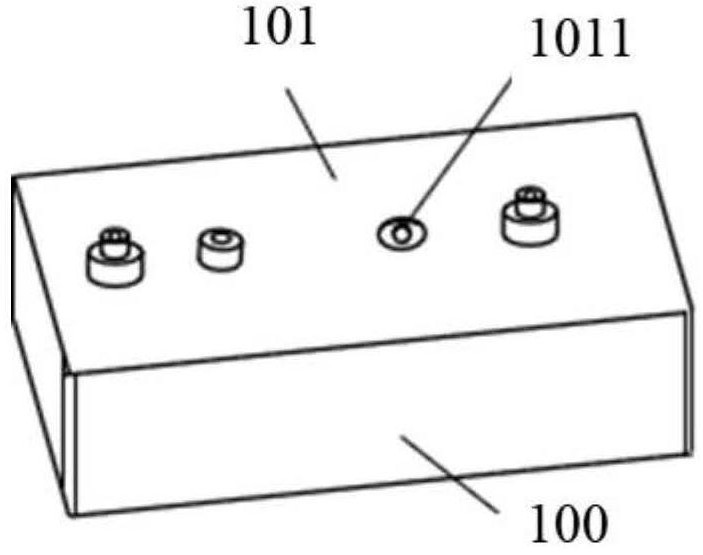

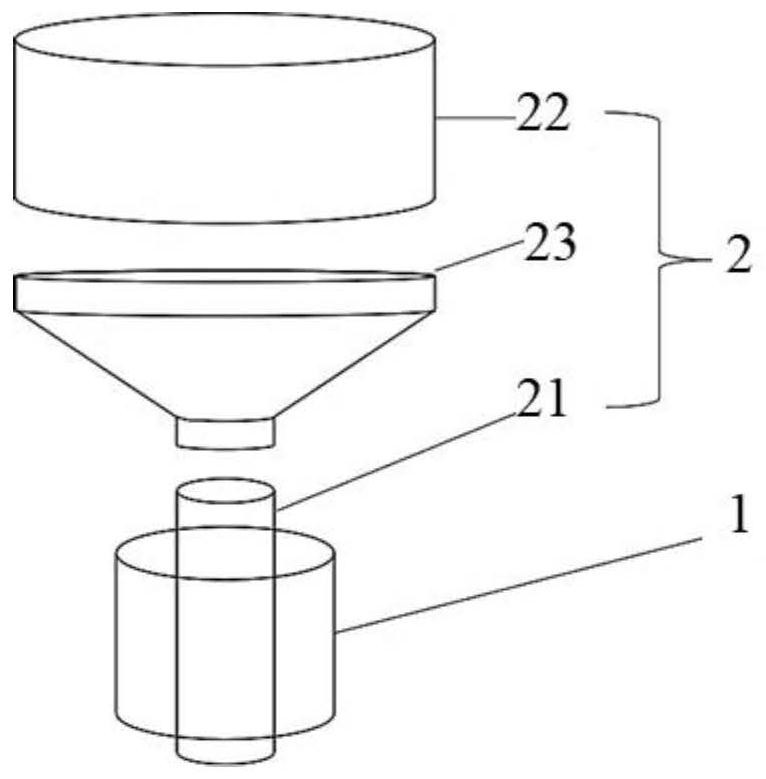

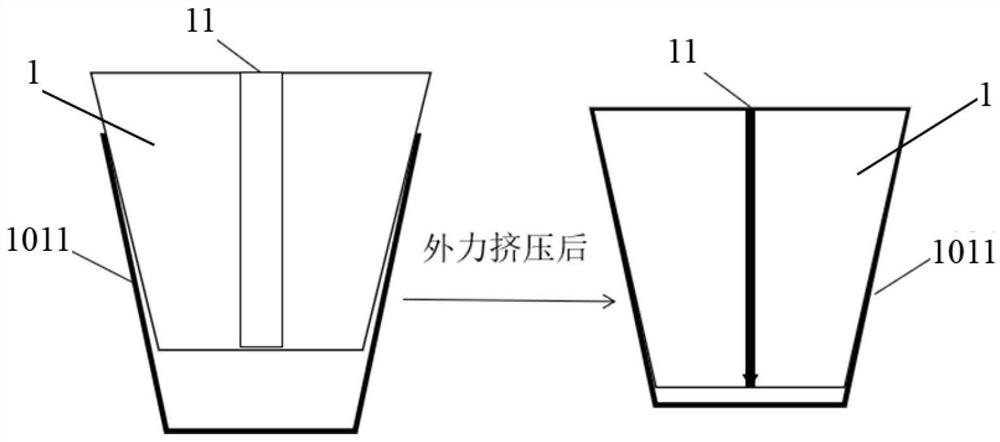

[0056] Such as Figure 1-Figure 5 As shown, this embodiment provides a sealing assembly for the formation and liquid replenishment process of the battery 100. The upper cover 101 of the battery 100 is provided with a liquid injection hole 1011 that is wide at the top and narrow at the bottom. The sealing assembly includes a sealing nail cylinder 1 And the external pipeline 2, the sealing nail cylinder 1 is made of silica gel or rubber, the sealing nail cylinder 1 can be inserted into the liquid injection hole 1011 and can shrink and deform under the action of the inner wall of the liquid injection hole 1011, wide at the top and narrow at the bottom The liquid injection hole 1011 is convenient to squeeze the sealing nail cylinder 1 to close the through hole 11 left by the external pipeline 2 on the sealing nail cylinder 1; the lower end of the external pipeline 2 can be inserted into the sealing nail cylinder 1 and extend into In the battery 100 , the upper end of the external ...

Embodiment 2

[0083] Such as Figure 6 As shown, this embodiment provides a sealing assembly, which differs from the sealing assembly provided in Embodiment 1 in that:

[0084] In the sealing assembly provided in this embodiment, the number of external pipelines 2 is multiple, and the multiple external pipelines 2 include a vacuum tube 24 and a liquid injection tube 25. The vacuum tube 24 and the liquid injection tube 25 are arranged side by side and can be inserted and sealed. The nail cylinder 1 extends into the battery 100, the upper end of the vacuum tube 24 is used to communicate with the vacuum pump, and the upper end of the liquid injection tube 25 is used to communicate with the pressurizing equipment.

[0085] Optionally, the vacuum tube 24 and the liquid injection tube 25 are arranged side by side and fixedly connected, so as to insert both into the sealing nail cylinder 1 at the same time.

[0086] Optionally, the upper end of the vacuum tube 24 is provided with a vacuum pump co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com