Processing method of film-coated apples

A processing method and technology of apples, applied in the direction of protecting fruits/vegetables with a coating protective layer, can solve the problems that the apple coating operation cannot be realized, and achieve the effect of avoiding collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

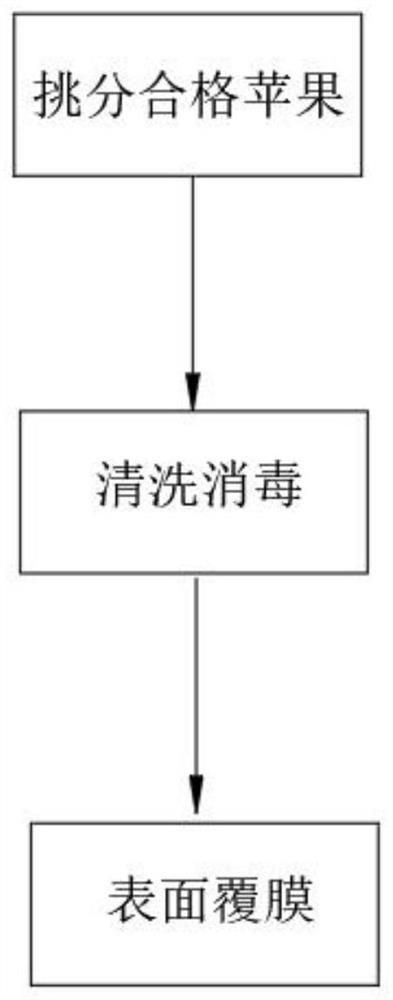

[0033] A method for processing coated apples, comprising the following steps

[0034] Step 1: Select the picked apples;

[0035] Step 2: Clean and disinfect qualified apples;

[0036] Step 3: Pass the apples into the coating device and cover with wax oil.

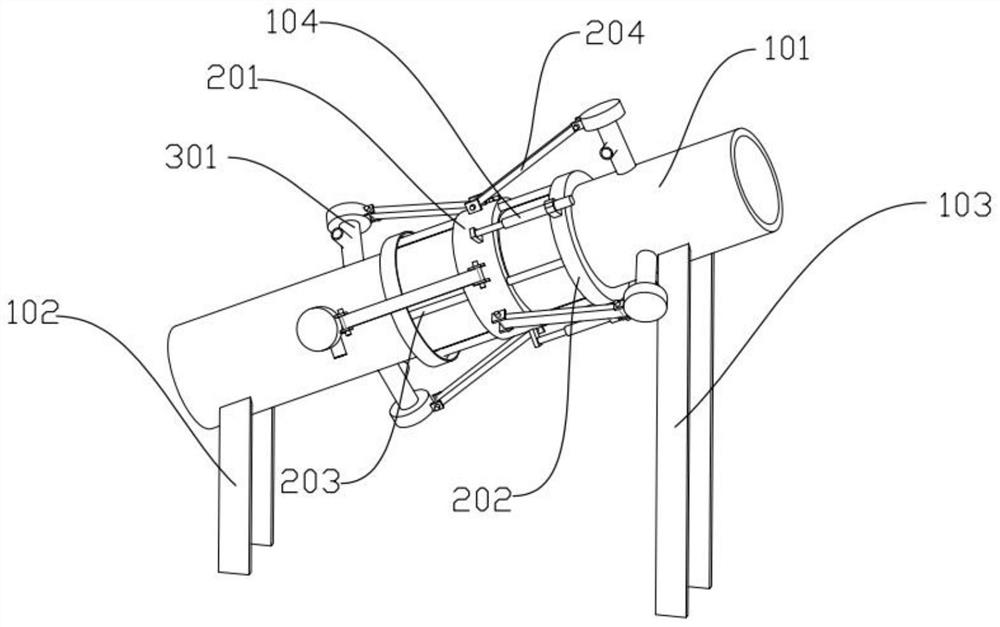

[0037] Also, as an example, such as figure 1 As shown, this example solves the problem of covering the apple with a layer of wax oil,

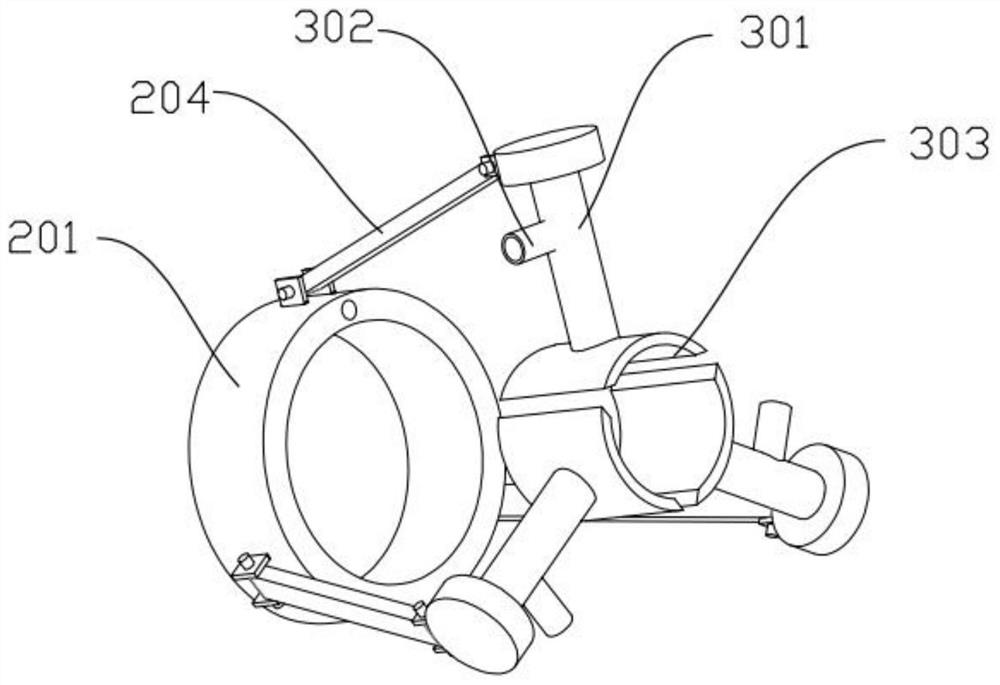

[0038] Since one end of the wax-coated barrel 101 is fixedly connected with two support parts I102, and the other end of the wax-coated barrel 101 is fixedly connected with two support parts II103, a plurality of round holes 107 are arranged at both ends of the wax-coated barrel 101, and a plurality of round holes 107 A plurality of wax-coated parts 301 are slidably connected inside. Since the heights of the support part I102 and the support part II103 are different, the support part I102 and the support part II103 can fix the wax-coated bucket 101 in an inclined posture, so that the Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com