Passive safety device of vehicle

A passive safety and vehicle technology, applied in the direction of freight vehicles, motor vehicles, transportation and packaging, etc., can solve problems such as unloading inconvenience, driver death, aggravating tragedies, etc., to avoid steel plate slipping, low cost, and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

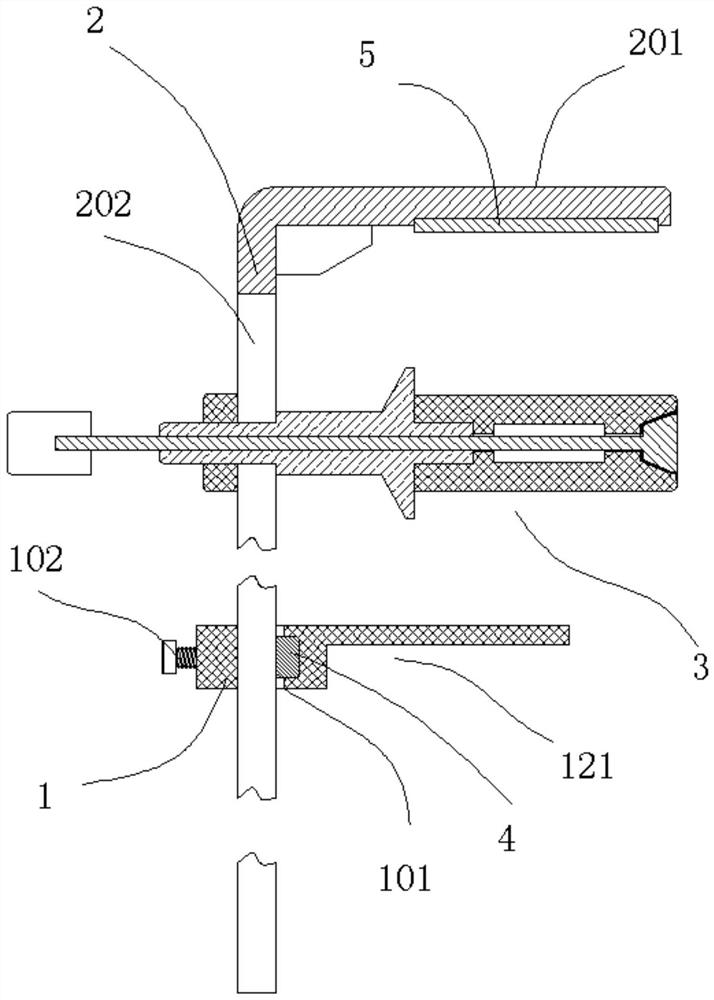

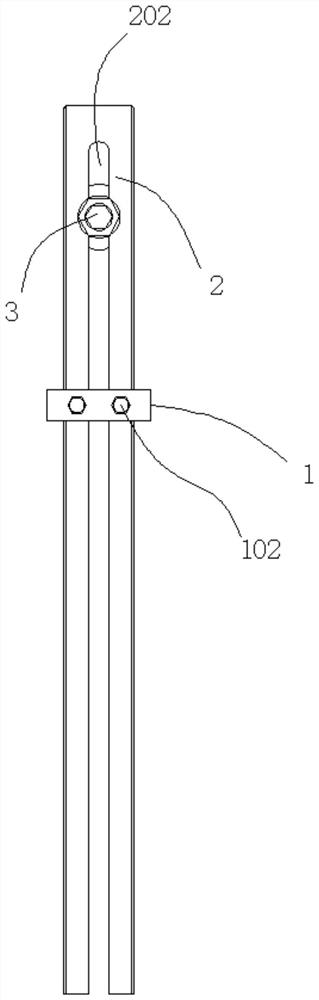

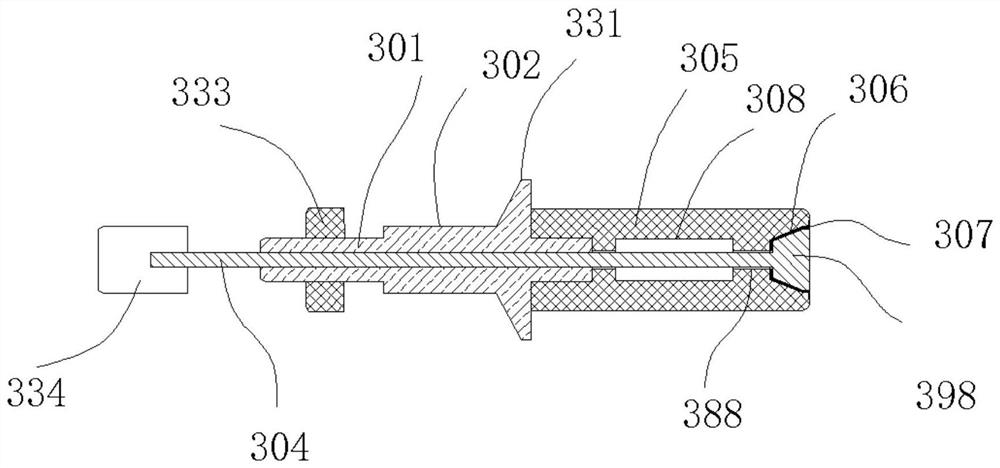

[0038] A passive safety device for a vehicle, comprising a bracket 1 installed on the side of the vehicle body, a vertically penetrating square groove 101 is arranged on the top of the bracket 1, and a side bar 2 is installed in the square groove 101, and the side bar 2 The upper end of the rod 2 is bent at right angles to form a limiting plate 201, and a bar-shaped groove 202 is arranged on the surface of the side plate 2, and the bar-shaped groove 202 runs through the side bar 2 downwards, and passes through the bar. The elastic spacer 3 is matched with the shaped groove 202 ; the screw 102 for fixing the side bar 2 is screwed into the outside of the bracket 1 .

Embodiment 2

[0040] On the groove wall of the through groove 101, the end corresponding to the screw 102 is provided with an embedding groove, and a rubber stopper 4 is embedded in the embedding groove, and the stopper 4 acts on the The side plate 2 and the stop block 4 are to increase the frictional resistance between the side plate and to avoid assembly gaps at the same time.

Embodiment 3

[0042] A first embedding groove is provided at the inner top position of the limiting plate 201, and a stop piece 5 is embedded in the first embedding groove; the stop piece 5 can prevent the gap between the steel plate and the limiting plate 201 during transportation The hard collision can also increase the contact friction with the steel plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com