Vacuum suction cup type outer jolt ramming device for low-temperature storage tank

A technology of low-temperature storage tanks and vacuum suction cups, which is applied in the direction of containers, large containers, packaging, etc. It can solve the problems of destructive product particle size, inability to install vibrators, and affect product quality, etc., to achieve compact structure and ensure thermal insulation performance , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

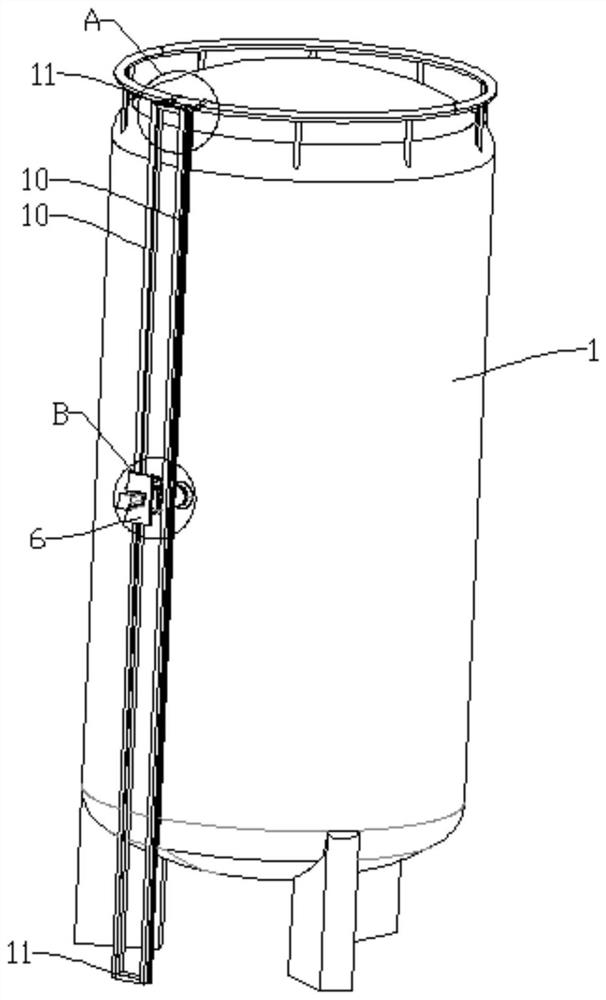

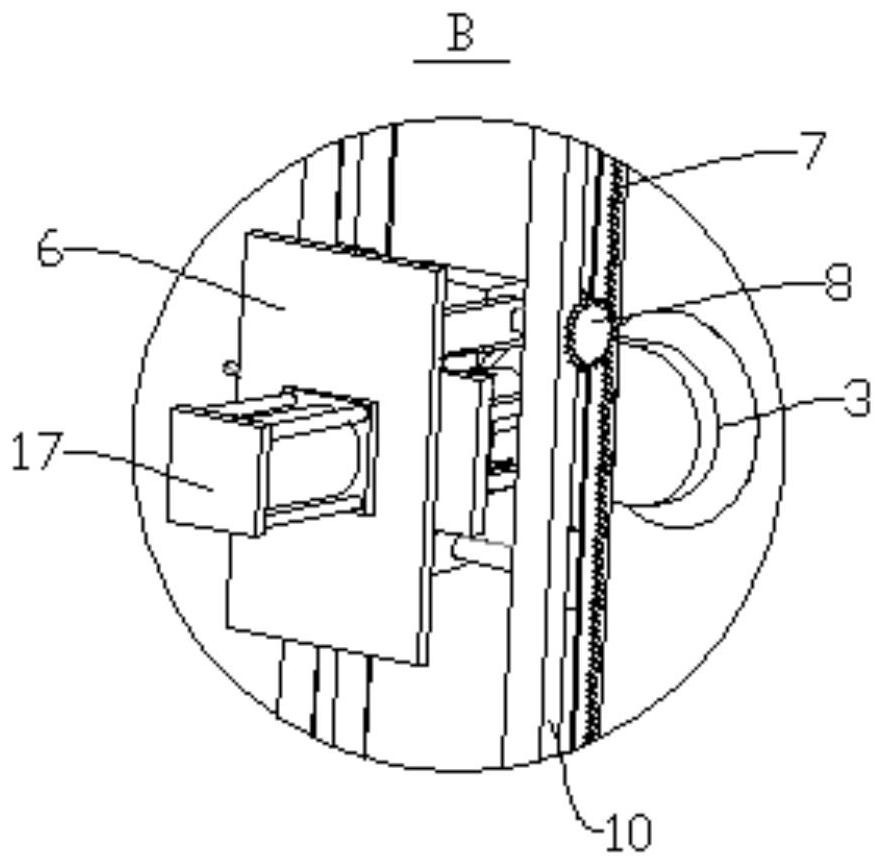

[0019] Such as figure 1 and image 3 In the shown embodiment, it mainly includes two hangers 10 symmetrically arranged left and right, and a lifting frame 6 capable of sliding up and down is arranged between the two hangers 10 . The front end of the lifting frame 6 is provided with a vibrating component, which can realize the vibration of the material in the cryogenic storage tank 1 .

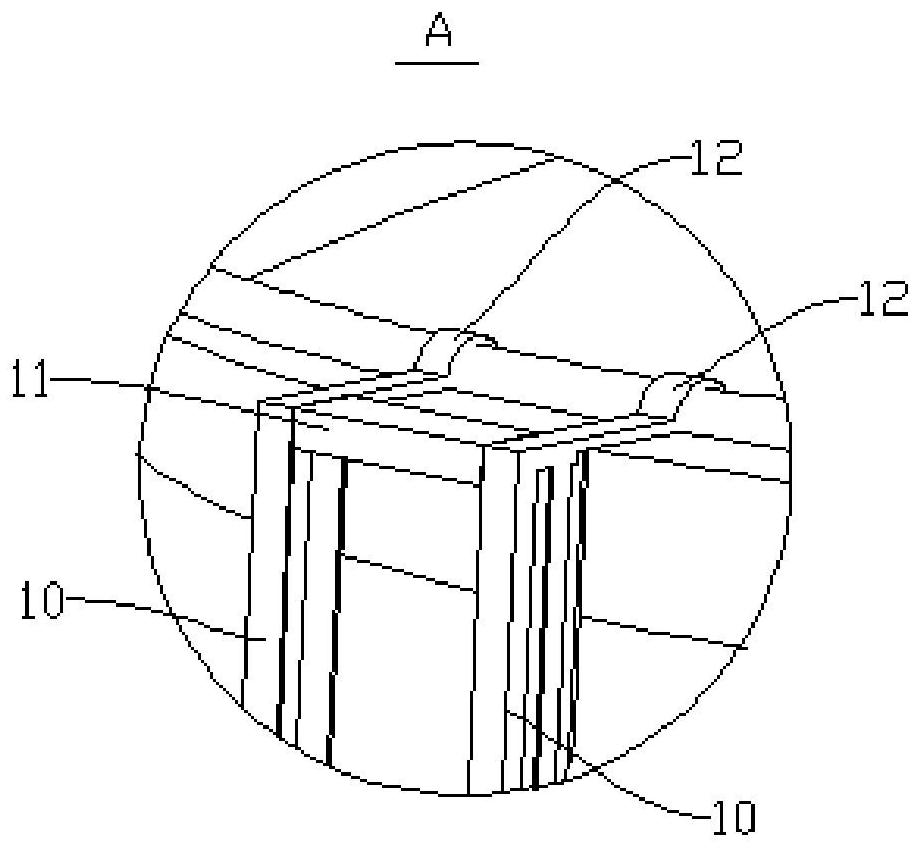

[0020] Such as figure 1 and figure 2 In the shown embodiment, crossbars 11 are arranged between the upper and lower parts of the two hangers 10, and the two hangers 10 are welded to both ends of the crossbars 11 respectively.

[0021] In order to facilitate the installation of the hanger 10 on the cryogenic storage tank 1, as figure 1 and figure 2 In the shown embodiment, the upper front ends of the two hangers 10 are respectively welded with hooks ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com