Batch wire arranging device for braided wire winding

A cable arrangement and braided wire technology, applied in the directions of transportation and packaging, transportation of filamentous materials, thin material handling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

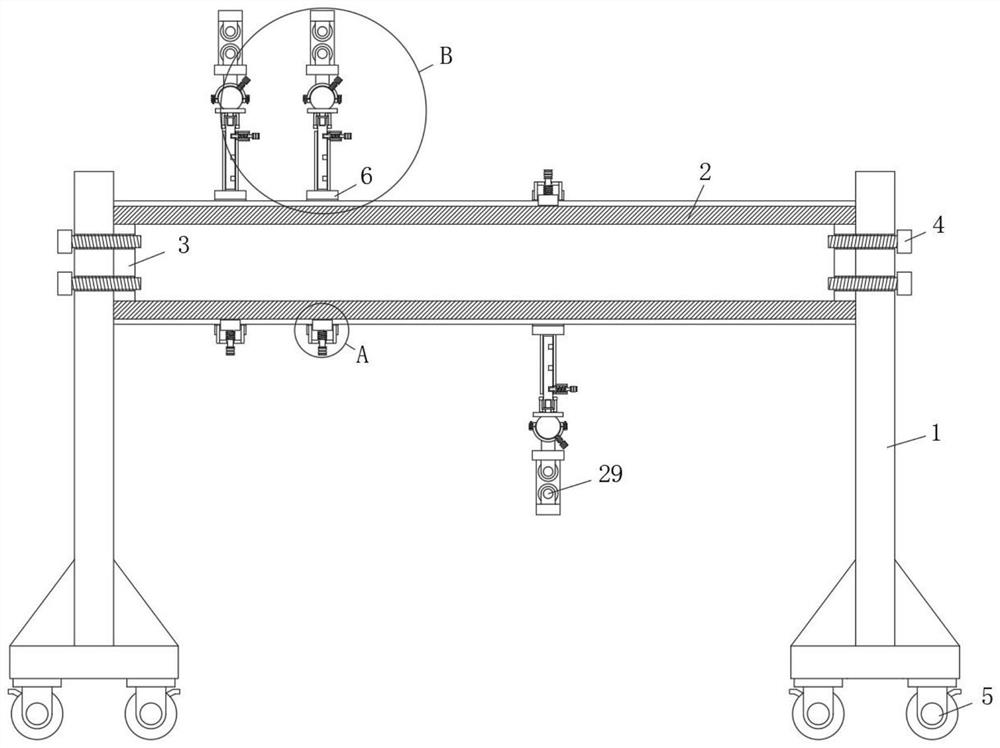

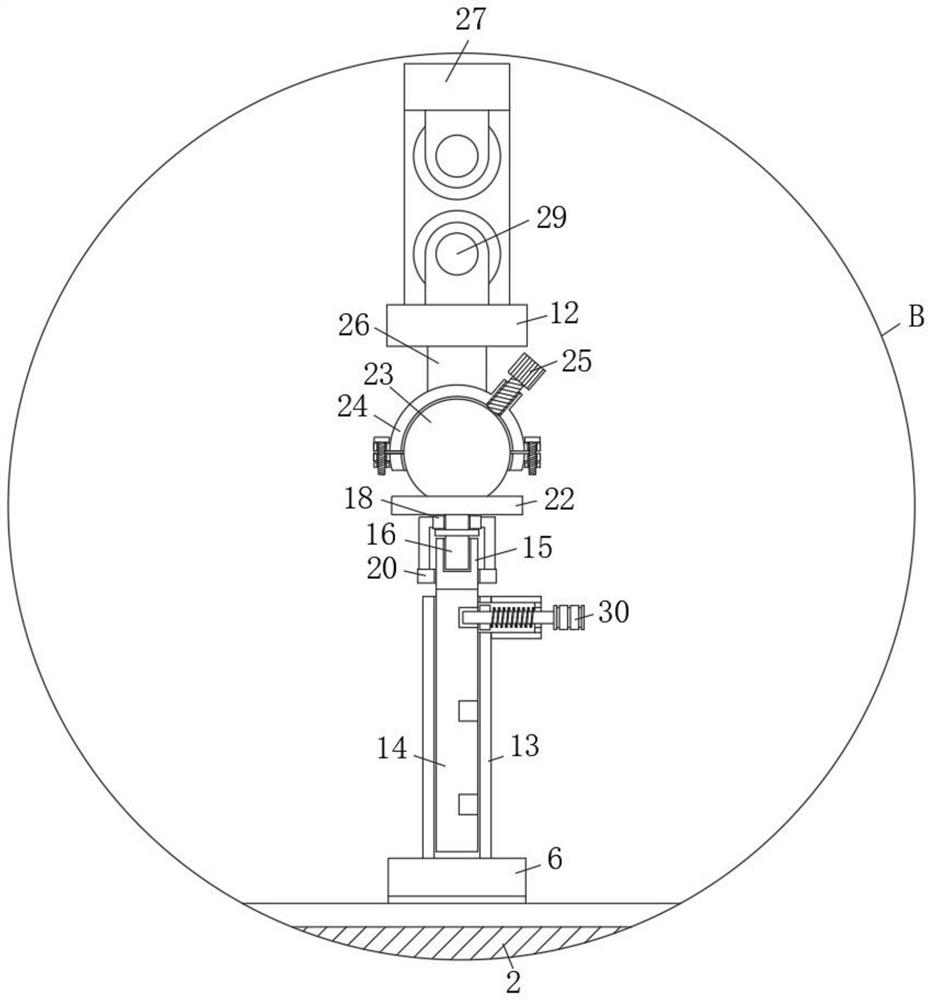

[0031] refer to Figure 1-5 , a batch wiring device for braided wire winding, comprising two vertically parallel vertical plates 1, a circular shaft tube 2 is arranged between the two vertical plates 1, and a sleeve is provided on the outer side of the circular shaft tube 2 for rotation 6. There is a fixing mechanism between the sleeve 6 and the cylindrical shaft 2, and one side of the sleeve 6 is provided with an installation end plate 12, and an adjustment mechanism is provided between the installation end plate 12 and the sleeve 6, and the installation end plate 12 is far away from One side of the casing 6 is provided with a U-shaped coaming plate 27, and the inner side of the U-shaped coaming plate 27 and the side where the end plate 12 is installed are symmetrically installed with a wire-passing roller 29;

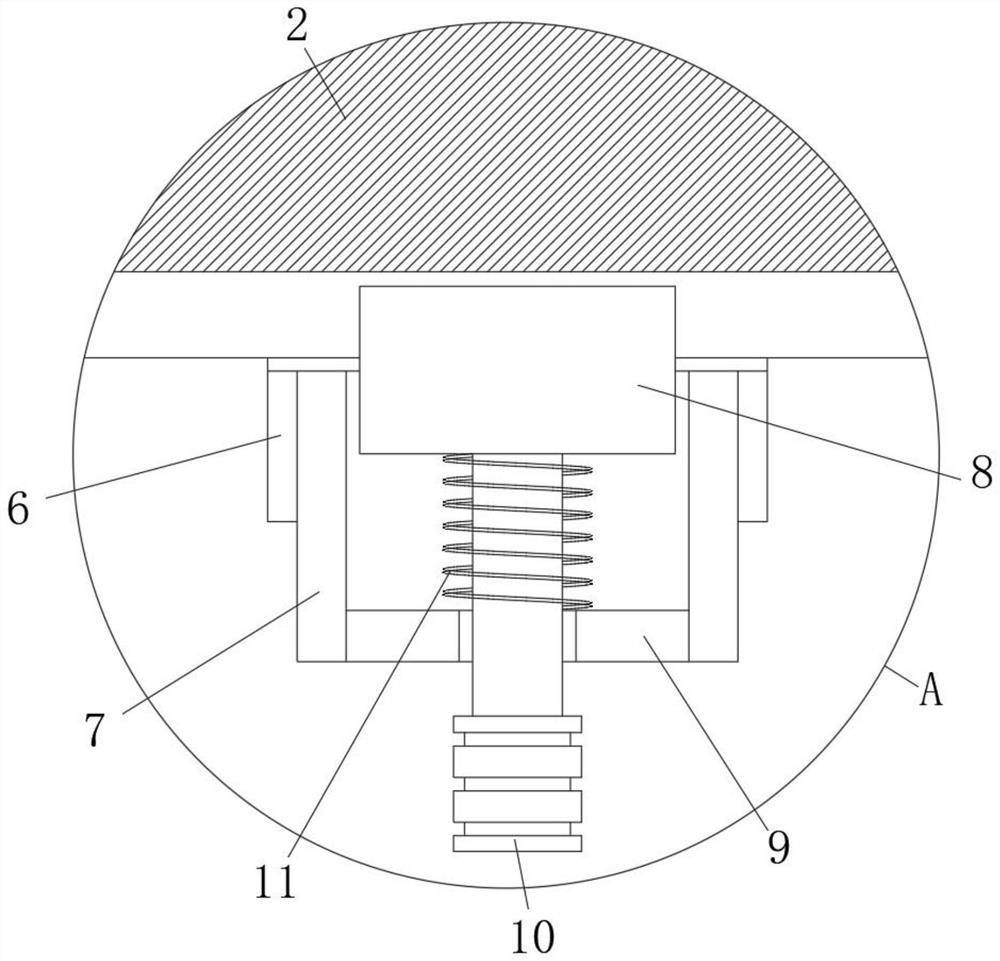

[0032] The fixing mechanism includes a vertical tube 7 fixed on the tube wall of the casing 6. The outer side of the cylindrical shaft tube 2 is divergently provided ...

Embodiment 2

[0038] like Figure 1-5 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the inner walls of both ends of the cylindrical shaft 2 are fixedly connected with the installation inner plate 3 , and a fixing bolt 4 is arranged between the installation inner plate 3 and the vertical plate 1 .

[0039] In this embodiment, it is easy to disassemble, so that the device can select a corresponding number of sleeves 6 according to the number of strands of the braided wire.

Embodiment 3

[0041] like Figure 1-5As shown, this embodiment is basically the same as Embodiment 1. Preferably, one end of the handle 10 slides through the inner side of the track ring 9 and is provided with anti-slip grooves.

[0042] In this embodiment, it is convenient for people to adjust the angle of the casing 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com