Mixed oil conveying pipeline facilitating mixed oil cutting

It is a technology for mixing oil and pipelines, which is applied in pipeline protection, pipeline anti-corrosion/rust protection, pipes/pipe joints/fittings, etc. It can solve the problems of oil influence along the line, difficult cutting, poor cutting effect, etc., and achieve stability And the effect of high safety in use, strong adjustability, and reduced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

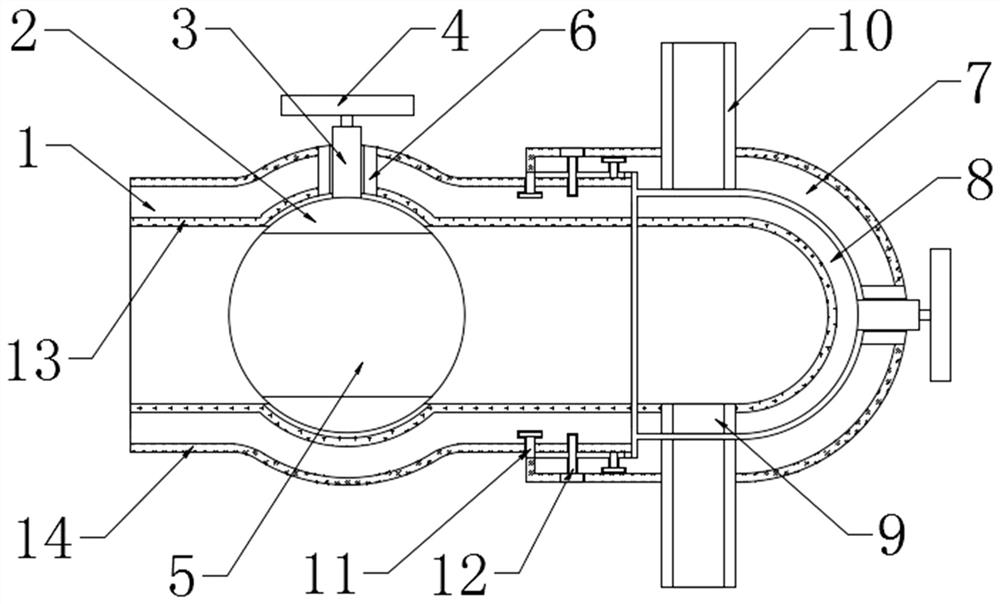

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

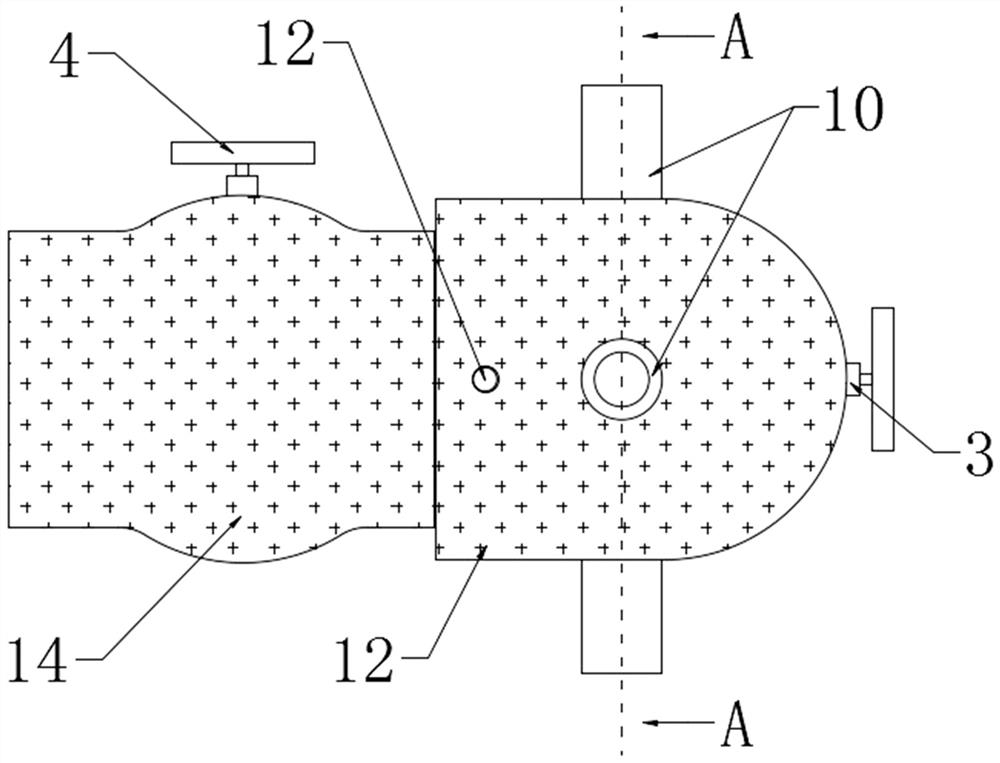

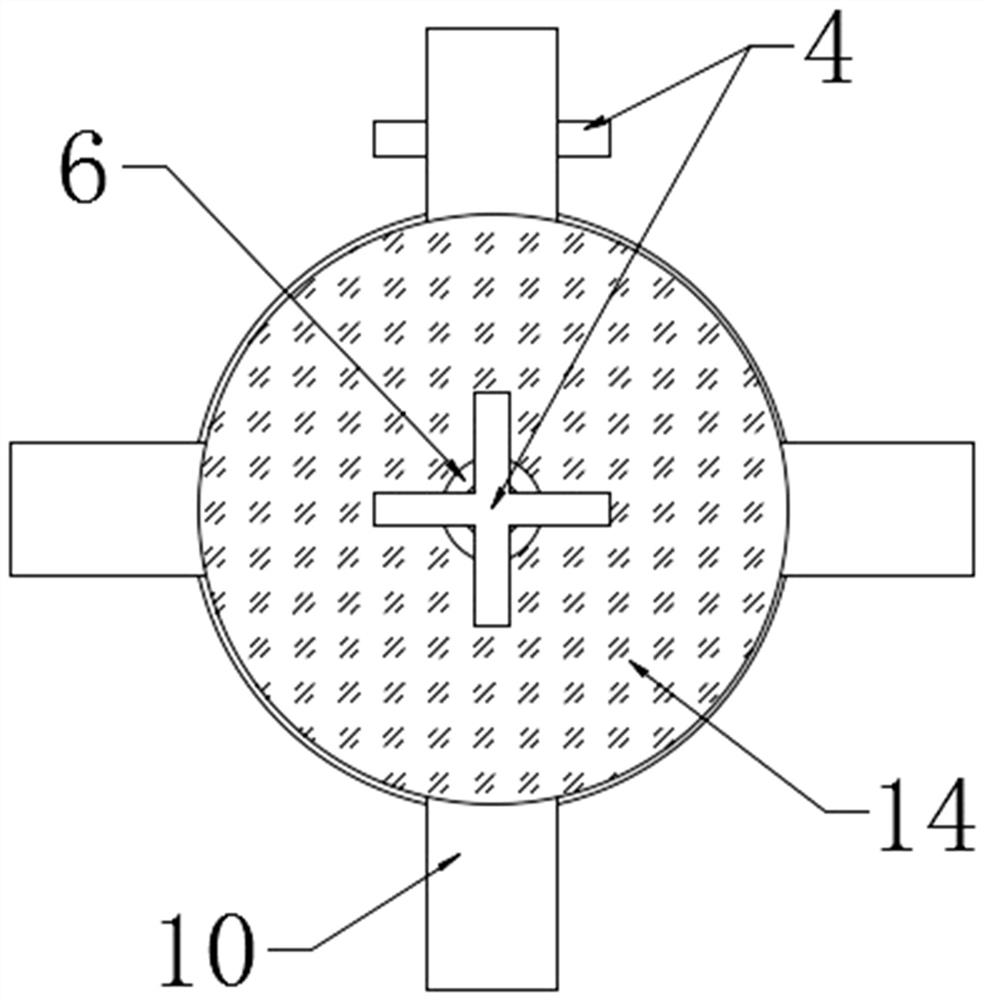

[0025] refer to Figure 1-Figure 4 , a pipeline for mixed oil transportation that is convenient for mixed oil cutting. 1 The side wall is provided with a connecting block 7, the connecting block 7 is connected with the main pipe 1 with a limit slider 11 and a fixing bolt 12, and the inner side of the connecting block 7 is provided with a diversion valve ball 8, and the diversion valve ball 8 The side wall is provided with a diversion groove 9, the side wall of the connecting block 7 is equipped with a branch pipe 10, the side wall of the diversion valve ball 8 and the control valve ball 2 are all equipped with a rotating shaft 3, and the rotating shaft 3 is far away ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com