Multi-layer film type acoustic meta-material structure and design method thereof

An acoustic metamaterial and multi-layer film technology, applied in the field of acoustic metamaterial research, can solve the problems of narrow sound insulation frequency band and low sound insulation, and achieve the effect of increasing the amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

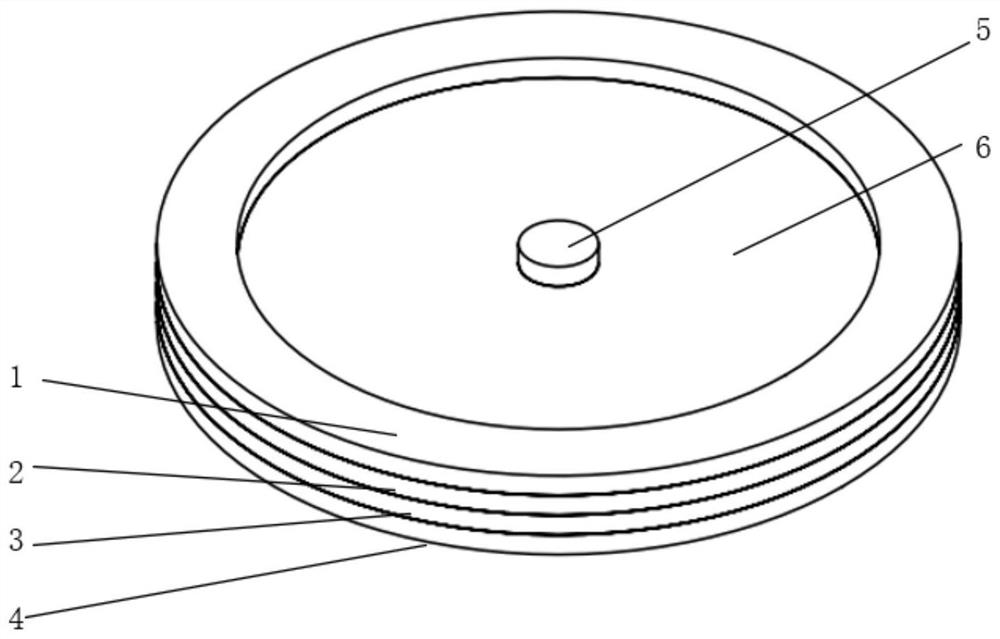

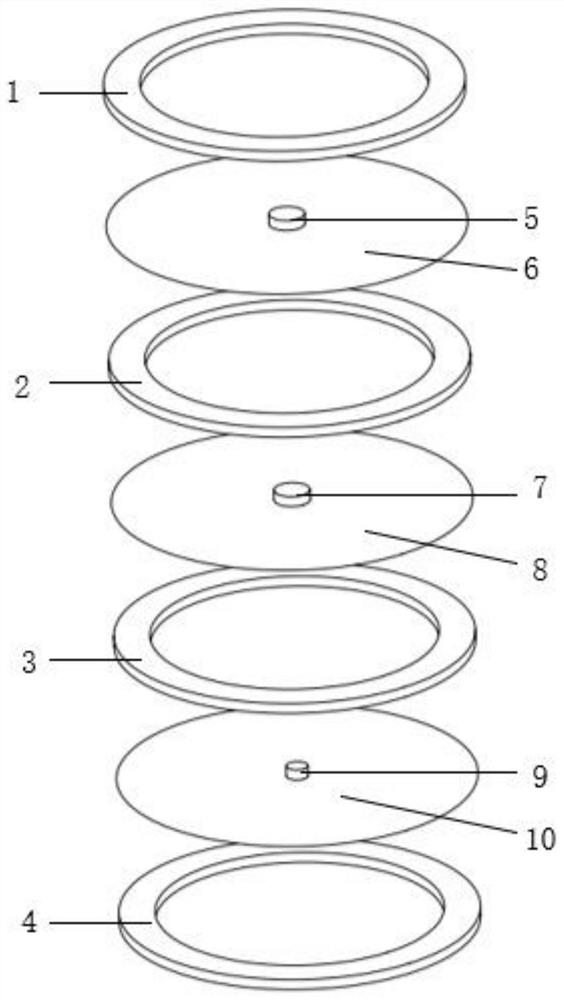

[0059] In this example, if figure 2 and image 3 As shown, a multi-layer thin-film acoustic metamaterial structure includes 3 stacked thin-film acoustic metamaterial units with different structural parameters, including the first frame 1 and the second frame for supporting the base and separating each metamaterial unit 2. The third frame 3 and the fourth frame 4, the first elastic film 6, the second elastic film 8 and the third elastic film 10 fixed between the frames after being tensioned, the first elastic film attached to each layer of elastic film respectively An additional mass 5, a second additional mass 7 and a third additional mass 9; ensure that the vibrations between the acoustic metamaterial units do not affect each other, forming a wide-band low-frequency sound insulation structure with multiple sound insulation peaks.

[0060] In this embodiment, the first frame 1, the second frame 2, the third frame 3 and the fourth frame 4 are all made of ABS resin material, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com