Cooling unit for an electrical machine and method for producing cooling unit

A technology for cooling units, machines, applied in electrical components, cooling/ventilation devices, manufacturing of motor generators, etc., can solve the problems of increased temperature, increased electrical machine packaging, i.e. outer size, less heat and material transport, etc., achieve the effect of avoiding repetition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

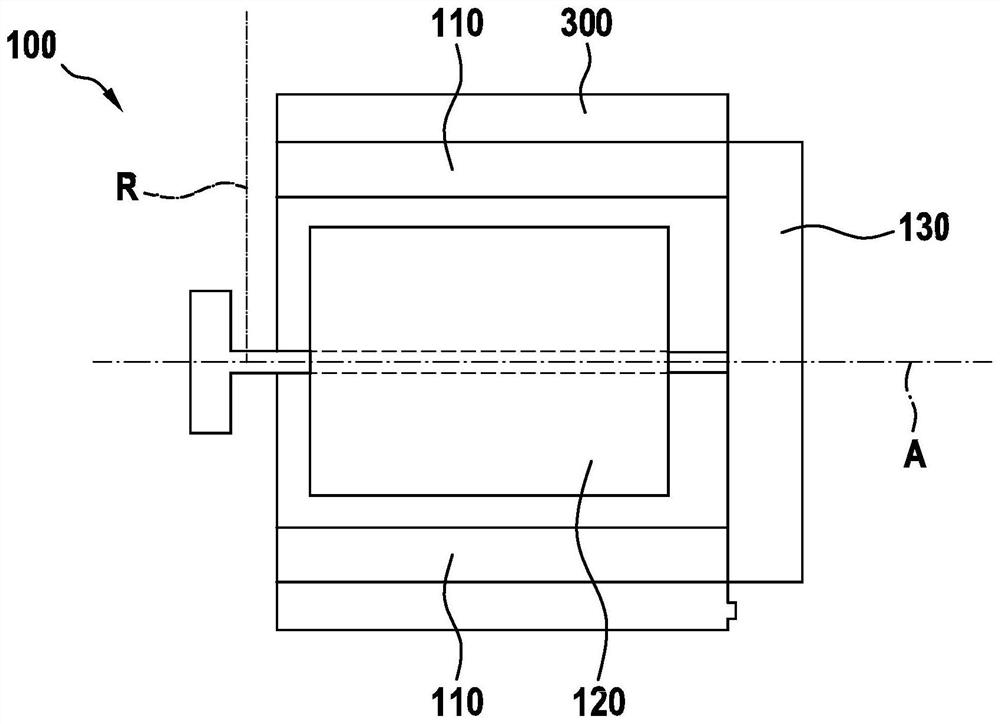

[0029] figure 1An electric machine 100 according to the invention with a cooling unit 300 is schematically shown in a preferred embodiment. The electric machine 100 has a stator 110 and a rotor 120 arranged inside the stator 110 , which is rotatable about an axis of rotation A, which also defines the axial direction. Let R correspond to the radial direction.

[0030] Furthermore, a control and regulation unit 130 is arranged, which has in particular a so-called inverter.

[0031] Cooling unit 300 has an at least substantially hollow-cylindrical jacket, or is designed substantially jacket-shaped, and is arranged around stator 110 . For a more detailed design of the cooling unit, see the subsequent drawings and related descriptions.

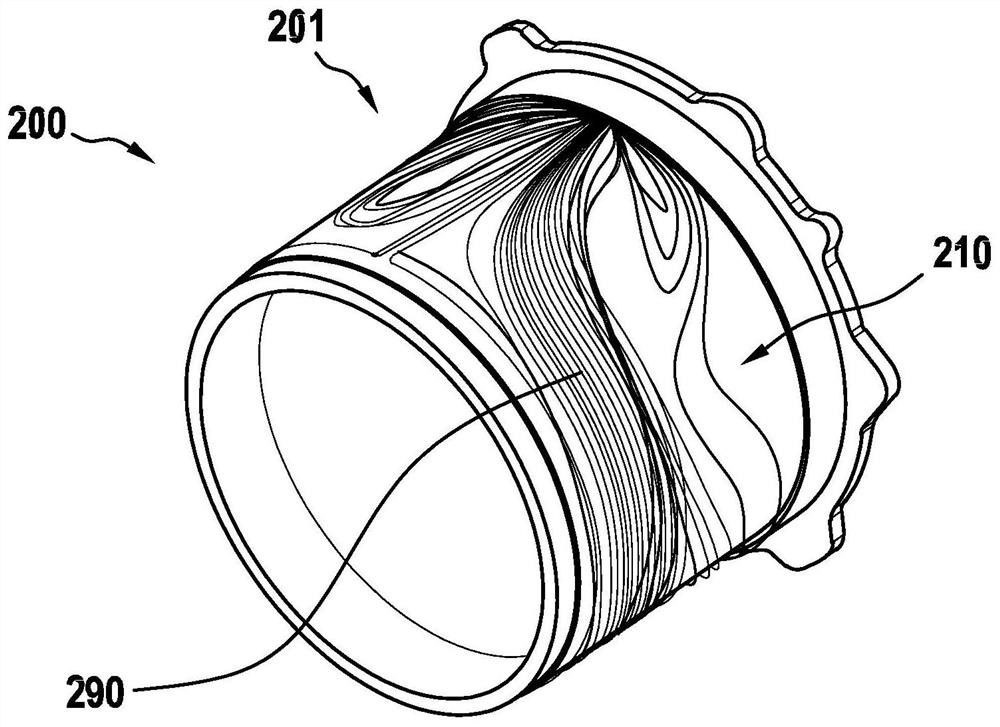

[0032] figure 2 A cooling unit 200 not according to the invention is shown in perspective view in FIG. The cooling unit 200 has a substantially hollow cylindrical envelope 201 , at least part of which is shown. Cooling channels 210 are provi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap