Pulverized coal sorting device

A sorting device and pulverized coal technology, which is applied in the direction of solid separation, separation of solids from solids by air flow, filtration and sieving, etc., can solve the problems of reducing the powder selection efficiency of the powder separator, not being able to automatically dredge, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

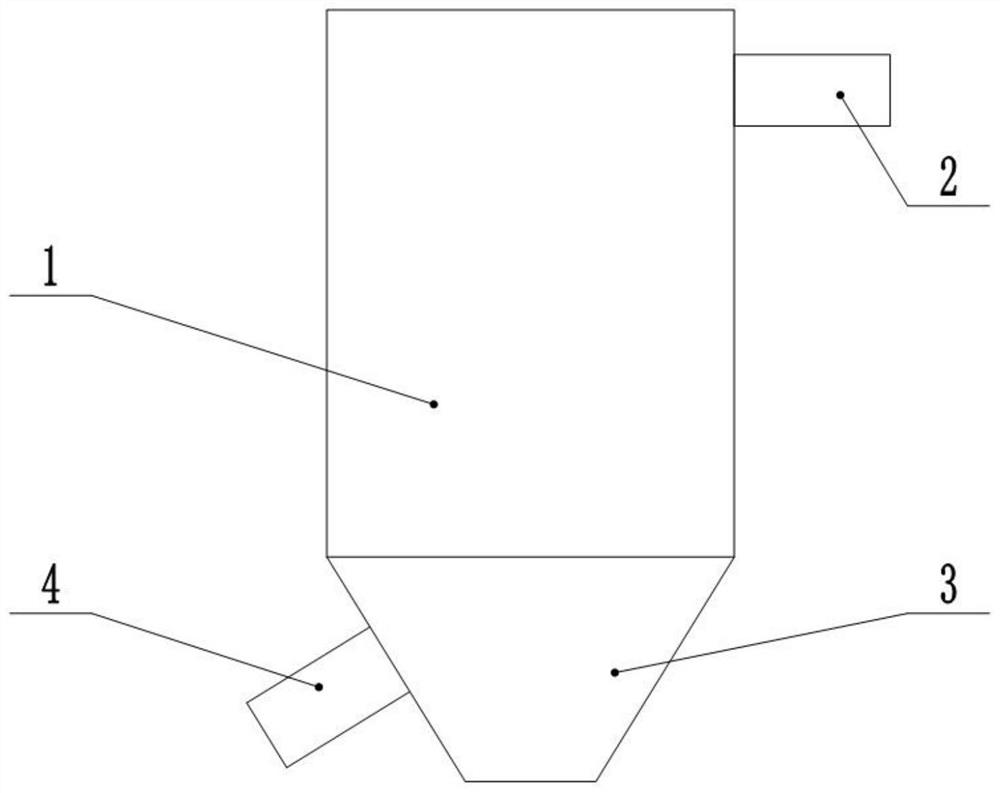

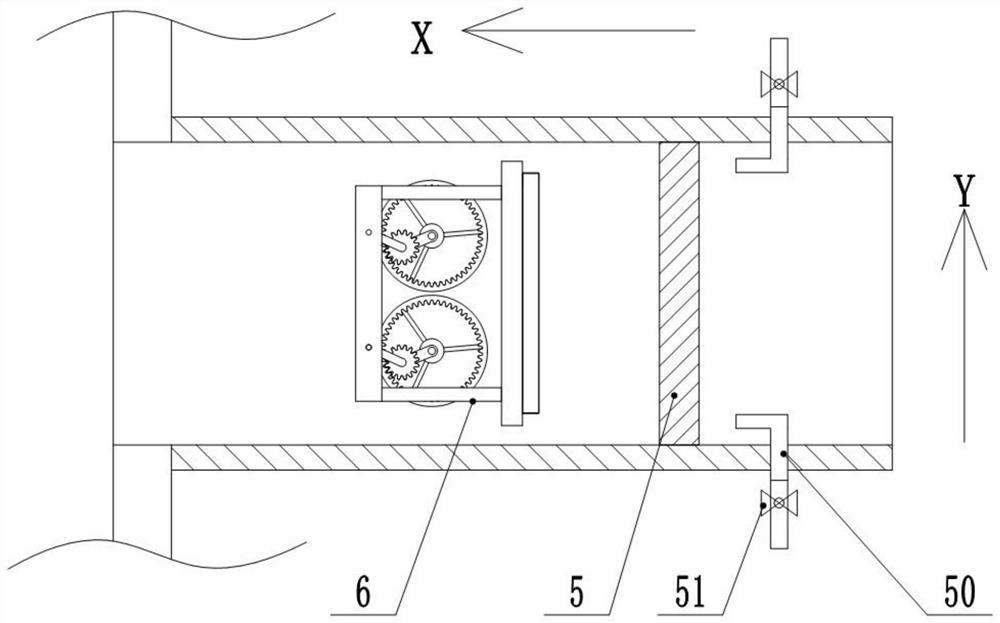

[0026] A pulverized coal sorting device, comprising a powder separator body 1, a fine powder discharge pipe 2 is arranged on the upper part of the powder separator body 1, a feed port 3 is arranged at the bottom of the powder separator body 1, and a bottom part of the powder separator body 1 is arranged There is a coarse powder discharge pipe 4, a filter screen 5 installed in the fine powder discharge pipe 2, and a dredging part 6 installed in the fine powder discharge pipe 2;

[0027] The powder separator body 1 is a purchased part, and its basic structure is a prior art, so the present application does not repeat it.

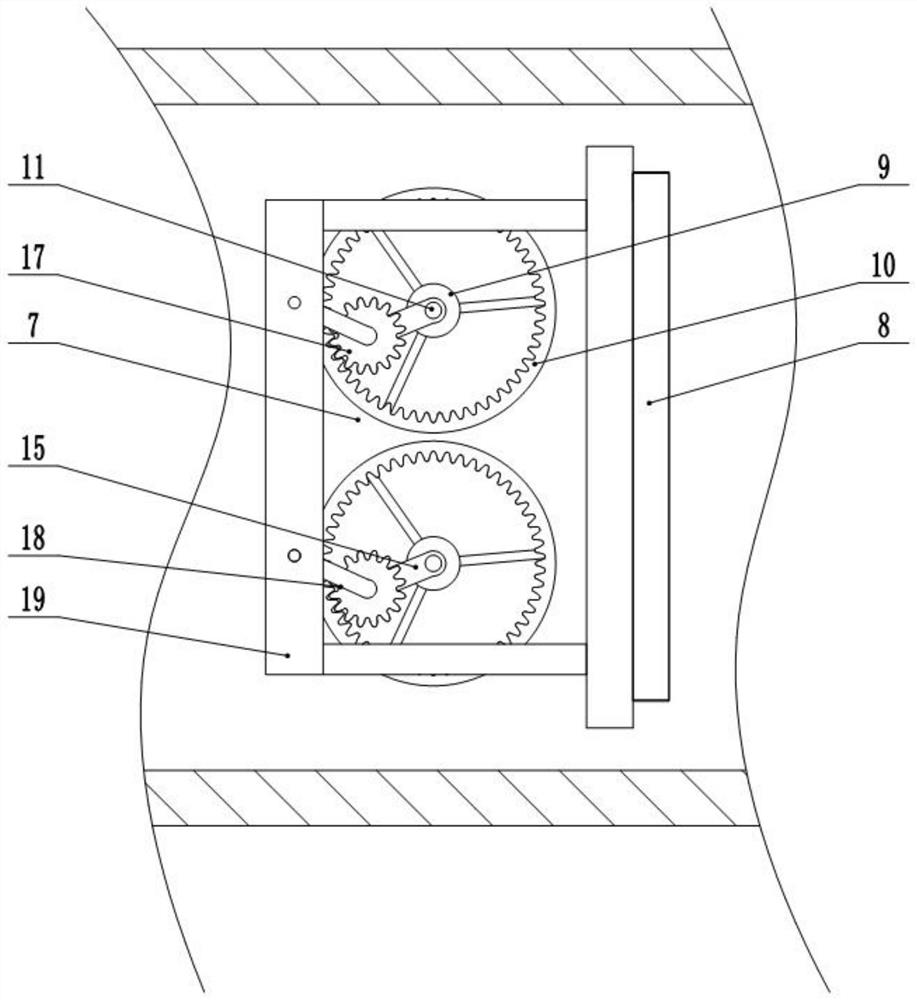

[0028] The dredging component 6 includes a driving assembly 7 installed in the fine powder discharge pipe 2, a knocking assembly 8 installed on the driving assembly 7 and expandable or contractible;

[0029] The drive assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com