Automatic charging management control system and method for automatic guided vehicle

An automatic guided vehicle and control system technology, applied in electric vehicle charging technology, charging stations, electric vehicles, etc., can solve the problems of coarse division, affecting the operation efficiency of AGV, and unable to guarantee the operation efficiency of AGV, so as to achieve high management and control efficiency. , the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

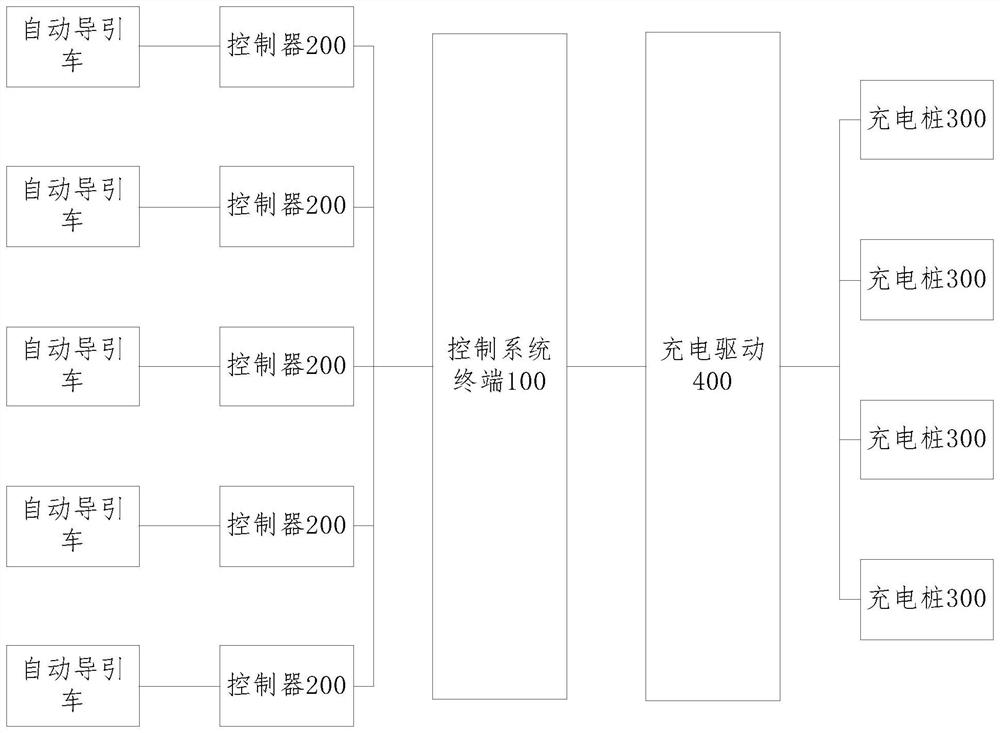

[0078] Such as figure 1 As shown, an automatic guided vehicle automatic charging management control system includes a control system terminal 100, a controller 200 for controlling the automatic guided vehicle, and a plurality of charging piles 300; the charging piles 300 are driven by charging 400 and controlled The system terminal 100 communicates; the charging pile 300 is used to charge the automatic guided vehicle, and the charging driver 400 is used to analyze, repackage and logically process the messages communicated between the charging pile 300 and the control system terminal 100; wireless communication between the control system terminal 100 and the controller 200.

[0079] It should be noted that the setting of the charging driver 400, as a communication middleware between the control system terminal 100 and the charging pile 300, acts as an adapter, so that the control system terminal 100 can communicate with various types of charging piles 300; Improve the flexibil...

Embodiment 2

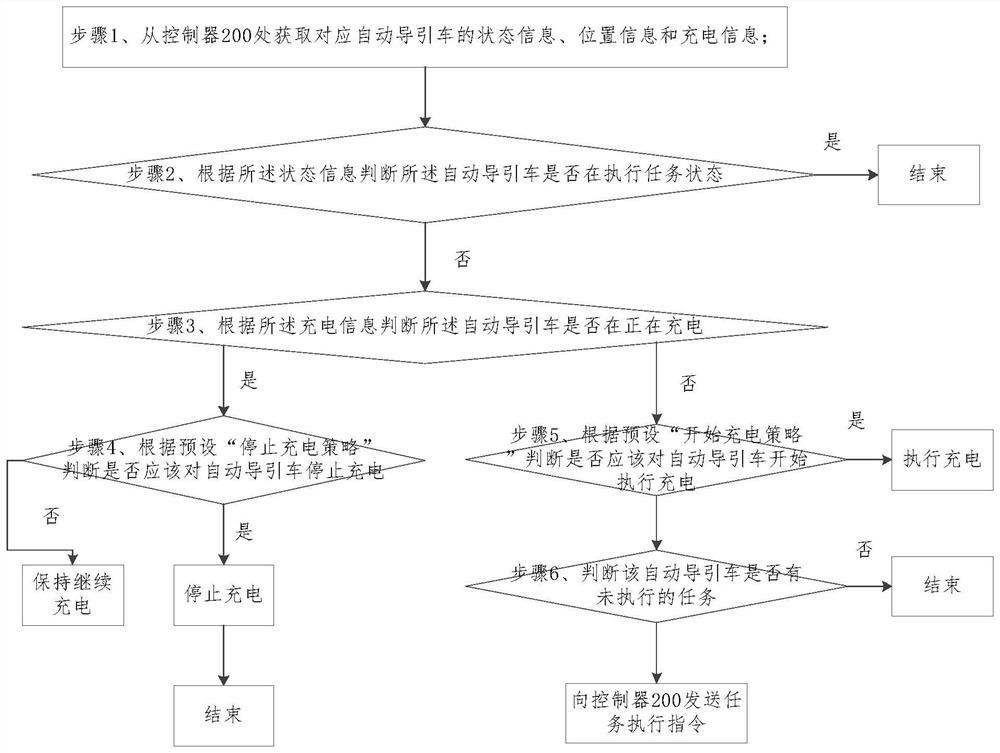

[0133] Such as Figure 4 As shown, an automatic guided vehicle automatic charging management control method regularly traverses all automatic guided vehicles in the current working scene, and performs the following steps for each automatic guided vehicle:

[0134] Step 1. Obtain the state information, location information and charging information of the automatic guided vehicle; the state information is used to reflect the state of the automatic guided vehicle, and the automatic guided vehicle has a task execution state and a non-execution task state; the The charging information is used to reflect whether the automatic guided vehicle is charging;

[0135] Step 2, judging whether the automatic guided vehicle is performing a task according to the status information, if so, then end; if not, then enter the next step;

[0136] Step 3, judging whether the automatic guided vehicle is charging according to the charging information, if yes, then proceed to step 4, if not, then proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com