Lifting device with cargo shaking preventing function for cargo transportation

A technology of cargo transportation and lifting devices, which is applied in the direction of transportation and packaging, hoisting devices, trolley cranes, etc. It can solve the problems of knotting together, damage to goods, messiness, etc., and achieve the effect of avoiding the shaking of goods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

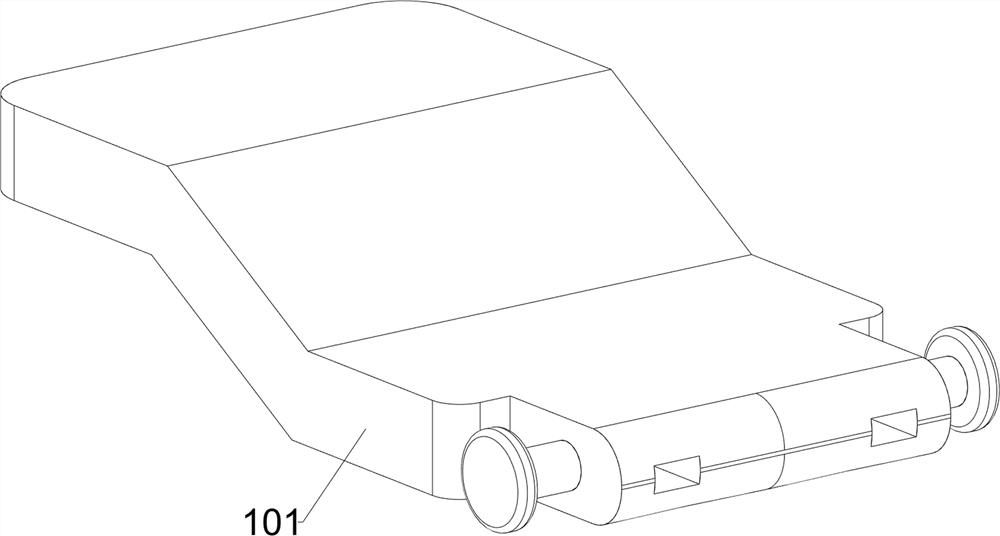

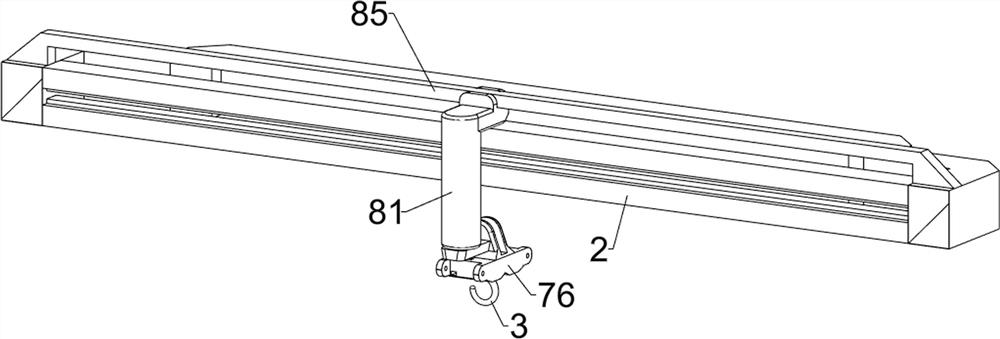

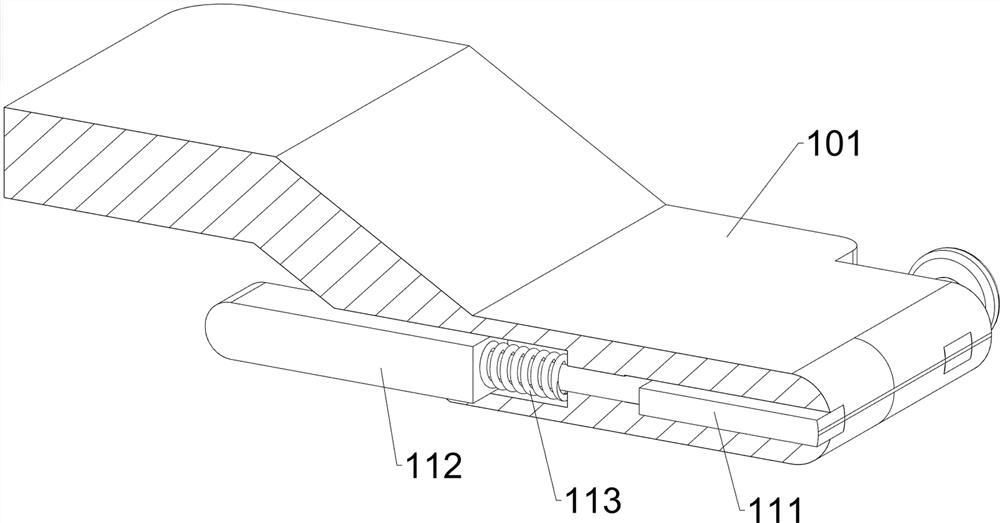

[0033] Such as Figure 1 to Figure 9 As shown, this embodiment discloses a lifting device with a function of preventing goods from shaking for transporting goods, including wheels 1, support frames 2, slide rails 21, hooks 3, first motors 4, second motors 5, and moving components 6 and the lifting assembly 7, the left and right sides of the four corners of the lower part of the support frame 2 are connected with wheels 1 in a forward and backward symmetrical rotation type, and a slide rail 21 is connected between the left and right sides of the upper part of the support frame 2, and the slide rail 21 is provided with a mobile assembly 6, The moving assembly 6 is provided with a first motor 4 and a second motor 5 , a lifting assembly 7 is provided between the rear side of the output shaft of the second motor 5 and the moving assembly 6 , and a hook 3 is provided on the lifting assembly 7 .

[0034] The moving assembly 6 includes a first roller 61, a support frame 62, a first pu...

Embodiment 2

[0039] Such as Figure 1 ~ Figure 3 , Figure 10 ~ Figure 15 As shown, in some embodiments, a uniform component 9 is also included, and the uniform component 9 includes a third pulley 91, a fourth pulley 92, a third transmission belt 93, a groove drum 94, a guide rod 95 and a slider 96, and the Wire pulley 71 transmission shaft rear ends are all connected with the 3rd belt pulley 91, and support frame 62 inner bottom, left and right sides are all connected with guide bar 95, all rotatably connected with groove tube 94 on the guide bar 95, and groove tube 94 rear sides are all connected The 4th belt pulley 92 is arranged, the 3rd transmission belt 93 is connected between the 3rd belt pulley 91 and the 4th belt pulley 92 on the left and right sides, and the sliding block 96 is all slidably connected on the guide bar 95, and the stay rope 72 on the left and right sides is all worn. Through the slider 96, the slider 96 cooperates with the groove tube 94.

[0040] The rotation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com