Power shift gearbox for wheel excavator

A power shifting and excavator technology, applied in the field of gearboxes, can solve the problems of many gears, low shifting efficiency, low efficiency, etc., and achieve the effects of compact internal structure, space utilization, and reliable shifting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

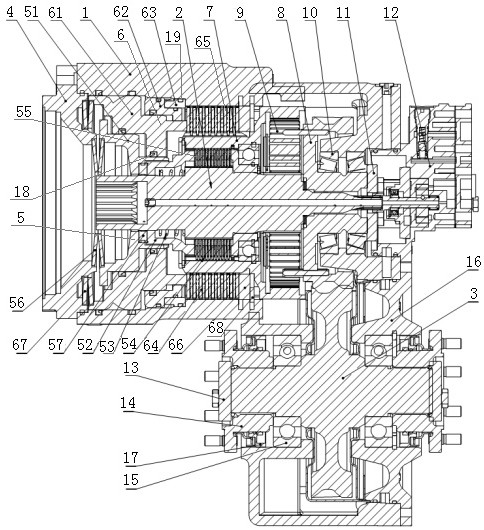

[0017] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a gear box 1, an input shaft 2 and an output shaft 3 are installed in the gear box 1, the front end of the input shaft 2 is connected to an input flange 4, and a low-speed clutch 5 is set on the input shaft 2, and the low-speed clutch 5 is connected with the gear box A high-speed clutch 6 is set between 1, and a ring gear 7 is arranged between the low-speed clutch 5 and the high-speed clutch 6. The external spline of the input shaft 2 meshes with the Samsung gear 9 installed on one side of the Samsung frame 8, and the Samsung frame 8 external teeth Mesh with the external teeth of the output shaft 3. The low-speed clutch 5 includes a low-speed plunger 51, a low-speed clutch plate top cover 52, a low-speed spring 53, a low-speed external tooth brake pad 54, a low-speed internal tooth friction plate 55, a low-speed disc spring 56 and a low-speed thrust bearing 57, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com