Novel reverse engaging gear shifting system

A new type of technology for driving gears, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve problems such as uneven shifting, engine and gearbox failures, strong frustration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

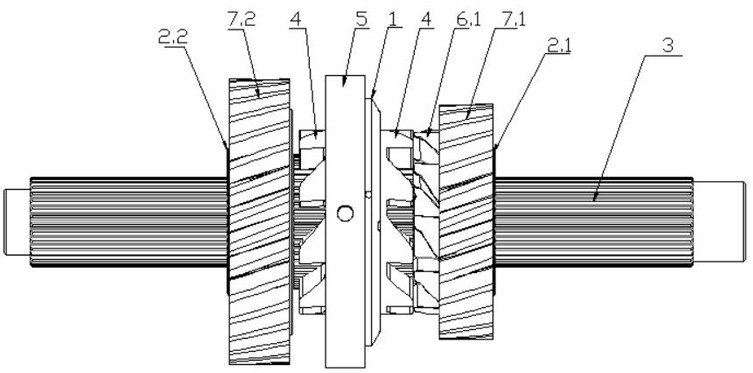

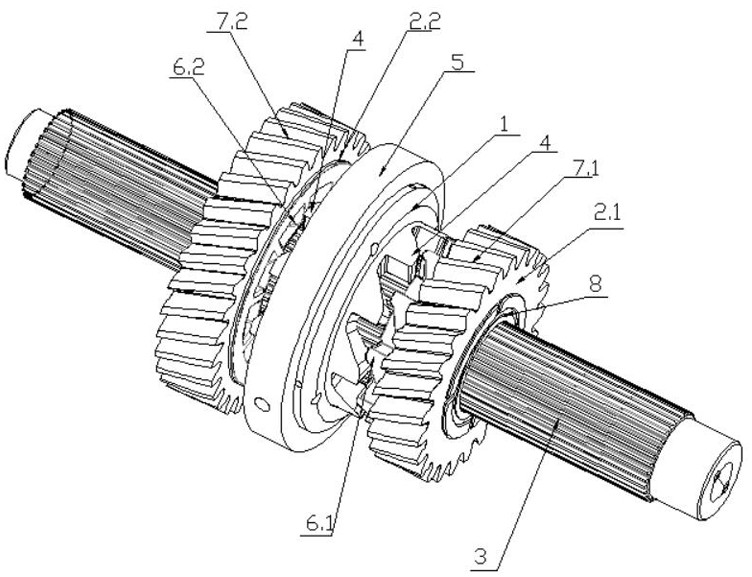

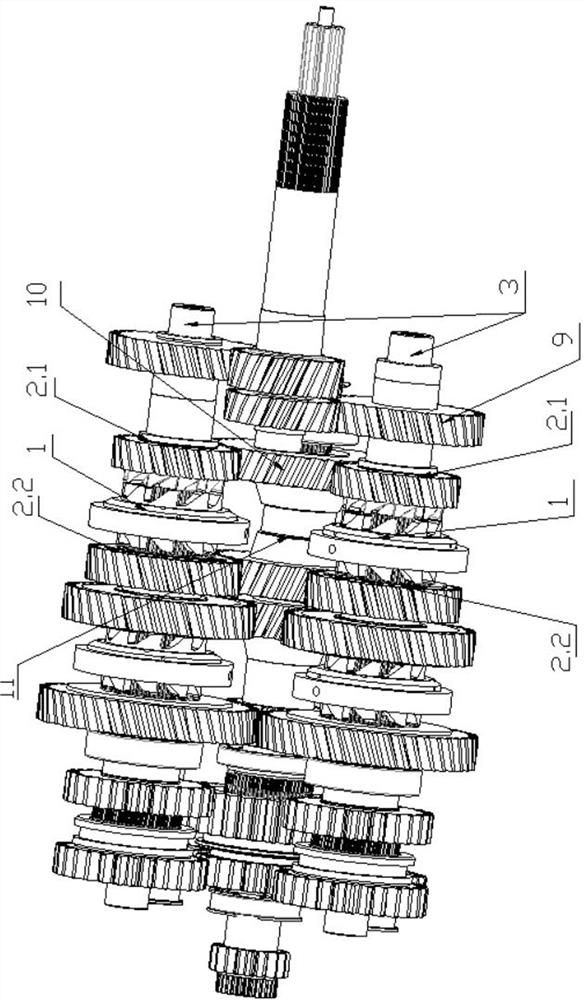

[0021] For the convenience of explanation, below in conjunction with the accompanying drawings, the novel inverse combination shifting system of the invention will be described in detail.

[0022] Such as Figure 1 to Figure 3 As shown in , a new type of reverse gear shifting system includes a drive gear 1 and a gear gear that cooperates with the drive gear 1. Only two gears are drawn in the figure, which are the first gear gear 2.1 and the second gear Gear gear 2.2, the specific number of gears can be designed according to the requirements of the gearbox, one drive gear moves left and right and two gears are combined to control two gears respectively, if there are four gears, two drive gears can be set .

[0023] The drive gear 1 and the gear gear are set on the same transmission shaft 3, the drive gear 1 and the transmission shaft 3 rotate synchronously, and the drive gear 1 can move axially along the transmission shaft 3 under the action of external force, and realize Eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com