Intelligent regulation and control method for high-speed motorized spindle water cooling system

A high-speed motorized spindle and water cooling system technology, applied in general control systems, control/regulation systems, adaptive control, etc., can solve problems such as limited cost, achieve optimization accuracy, good fitting and generalization ability, nonlinear The effect of strong fitting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

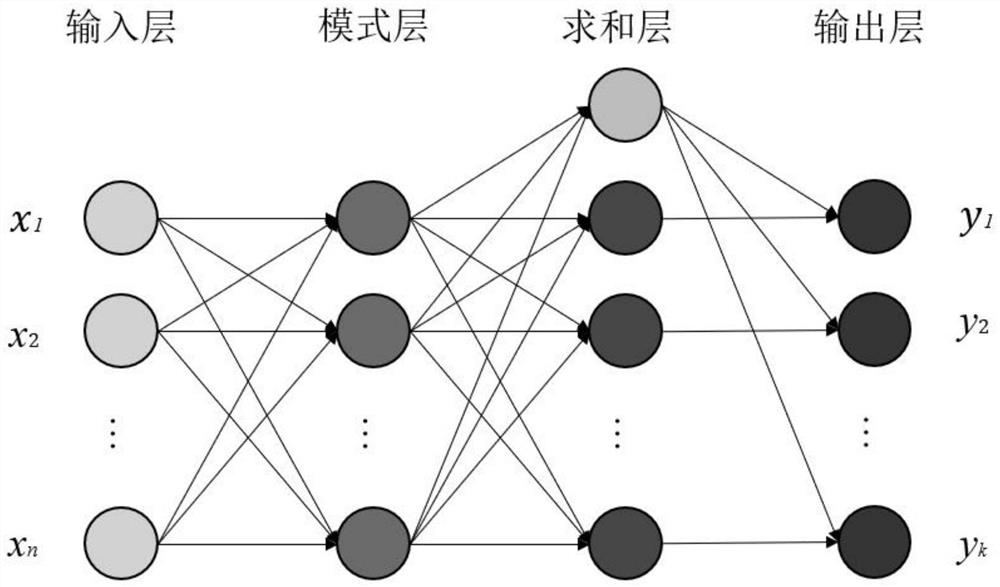

[0029] In this embodiment, the generalized neural network electric spindle thermal characteristic control cooling medium flow modeling method based on genetic algorithm optimization specific steps includes:

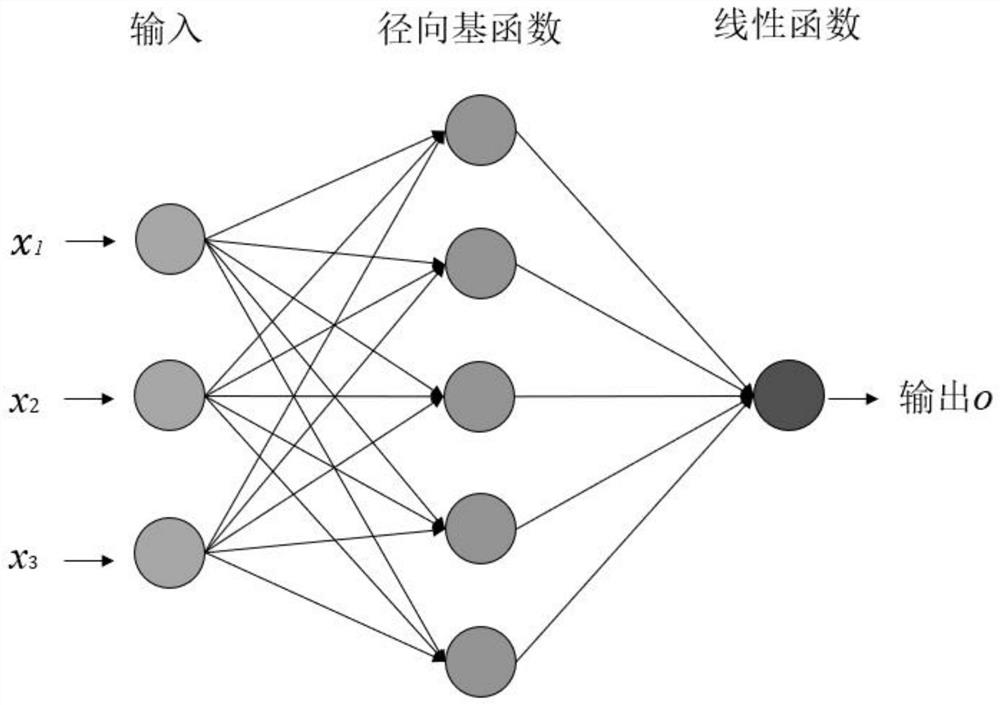

[0030] A. Establish RBF neural network structure

[0031] A1. The main feature of RBF neural network is that it can transform the problem in low-dimensional space into high-dimensional space to solve it, which also determines the characteristics of fast training of RBF neural network and the ability to solve any nonlinear problem.

[0032] Such as figure 1 As shown in the RBF network structure diagram, the independent variable of the radial basis function is a real number representing the distance, and its mathematical form can be expressed by the formula

[0033]

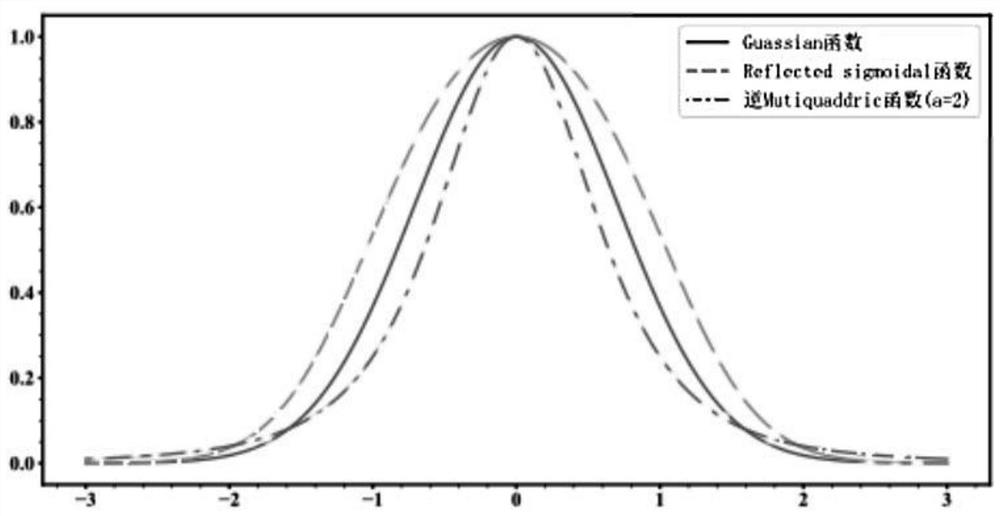

[0034] There are three types of radial basis functions:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com